The group has taken component in the producing and revising of ISO/TC100 worldwide chain common a number of many years in accomplishment and hosted the 16th ISO/TC100 International once-a-year conference in 2004.

Overview

Fast Particulars

-

Applicable Industries:

-

Producing Plant, Machinery Repair Retailers, Meals & Beverage Manufacturing unit, Printing Stores, Building works , Strength & Mining, Promoting Business

-

Material:

-

Metal

-

Regular:

-

ANSI

-

Spot of Origin:Zhejiang, China

-

Brand name Title:

-

OEM

-

Mechanical items:

-

transmission

-

Area therapy:

-

Blackout

-

Heat treatment:

-

Area quenching

-

Internal warmth remedy:

-

High quality treatment method

-

Standard or Nonstandard:

-

Nonstandard Plastic Gear

-

Machining Process:

-

Equipment hobbing machine

-

Software:

-

Sector Machinery

-

Description:

-

Electricity Transmission

-

Module:

-

12A

Provide Ability

-

Source Potential:

- ten thousand Piece/Items for every Month

Packaging & Shipping and delivery

- Packaging Details

- Wood scenario packing.

- Port

- HangZhou

-

Picture Case in point:

-

-

Lead Time

:

-

| Quantity(Pieces) |

one – a thousand |

>1000 |

| Est. Time(times) |

40 |

To be negotiated |

On-line Customization

Product Description

|

Merchandise title

|

indurstry sprocket

|

|

|

|

|

Material

|

C45,40Cr,20CrMnTi,42CrMo,Copper,Stainless steel and so on as for each your requests.

|

|

|

|

|

Processing method

|

Forging,Machining,Hobbing,Milling,Shaving, Grinding,Heat treatment

|

|

|

|

|

Heat Treatment

|

Carburizing,Induction,Flame,Nitriding

|

|

|

|

|

Main Equipment

|

Lathe, equipment shaper, hobbing equipment, CNC machining middle, drilling machine

|

|

|

|

|

Utilized

|

Equipment Plant, mining equipment, chemical market, glass equipment, three-dimensional garage

|

|

|

|

|

Our virtues

|

Manufacturing unit direct revenue, large good quality and lower price tag.

|

|

|

|

|

Export Marketplaces

|

North The us, South The usa, Eastern Europe, Southeast Asia, Africa, Oceania, Mid East, Jap Asia,

Western Europe

|

|

|

|

|

Software

|

Industry sprockets can be usedin power driving, conveyor, lifting, mine, agricultural, food industry and many others.,

Together with rollerchains

|

|

|

|

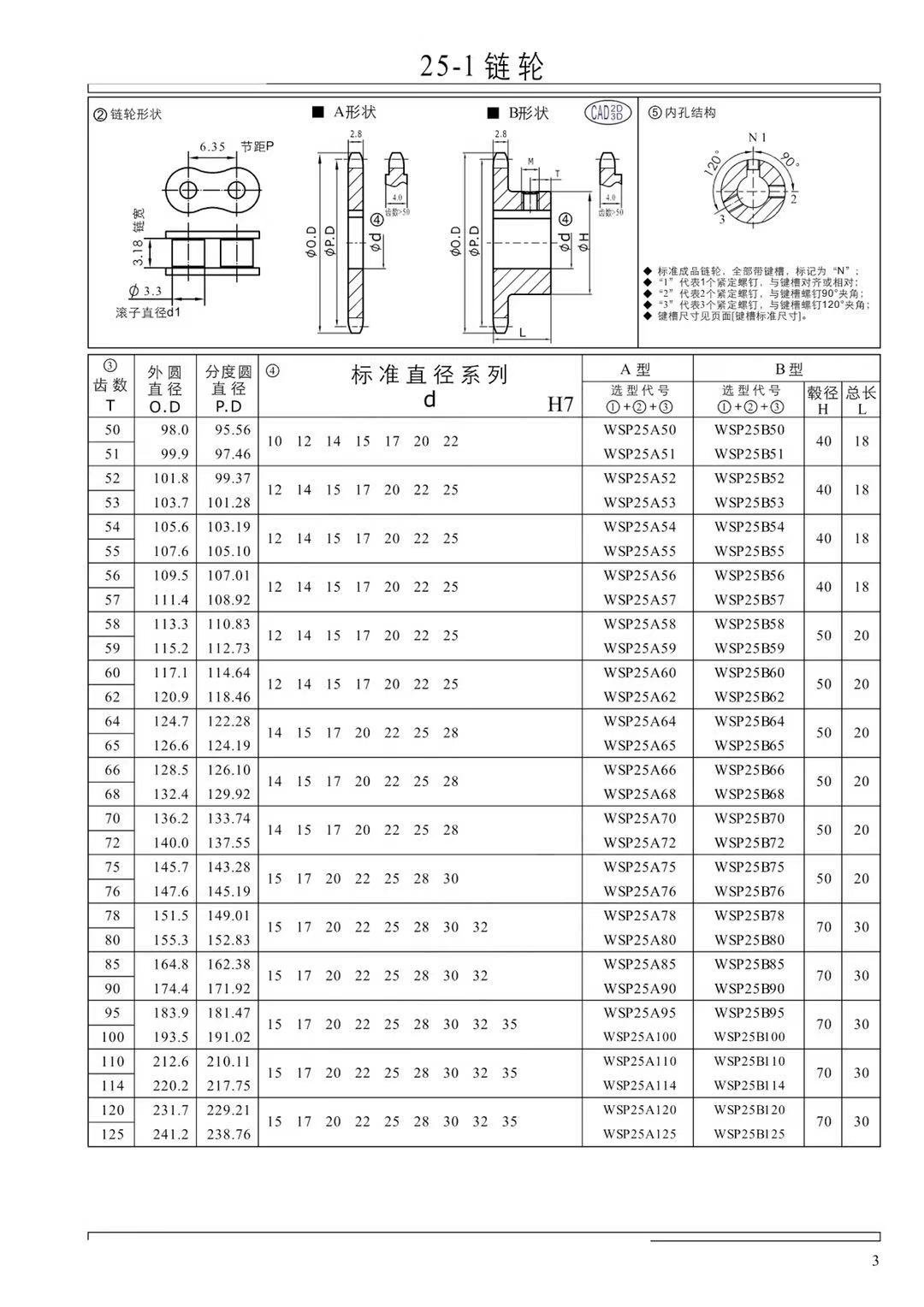

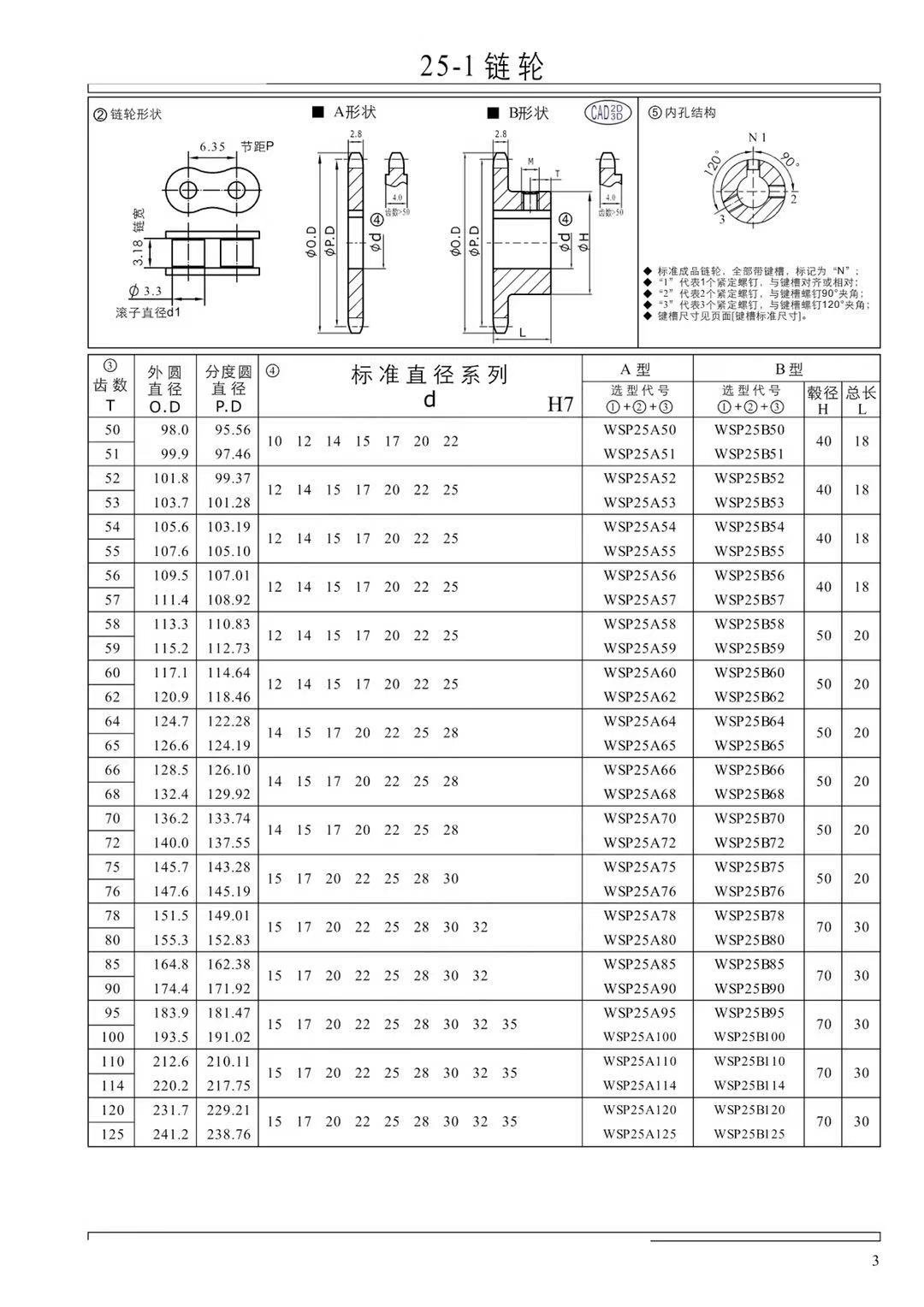

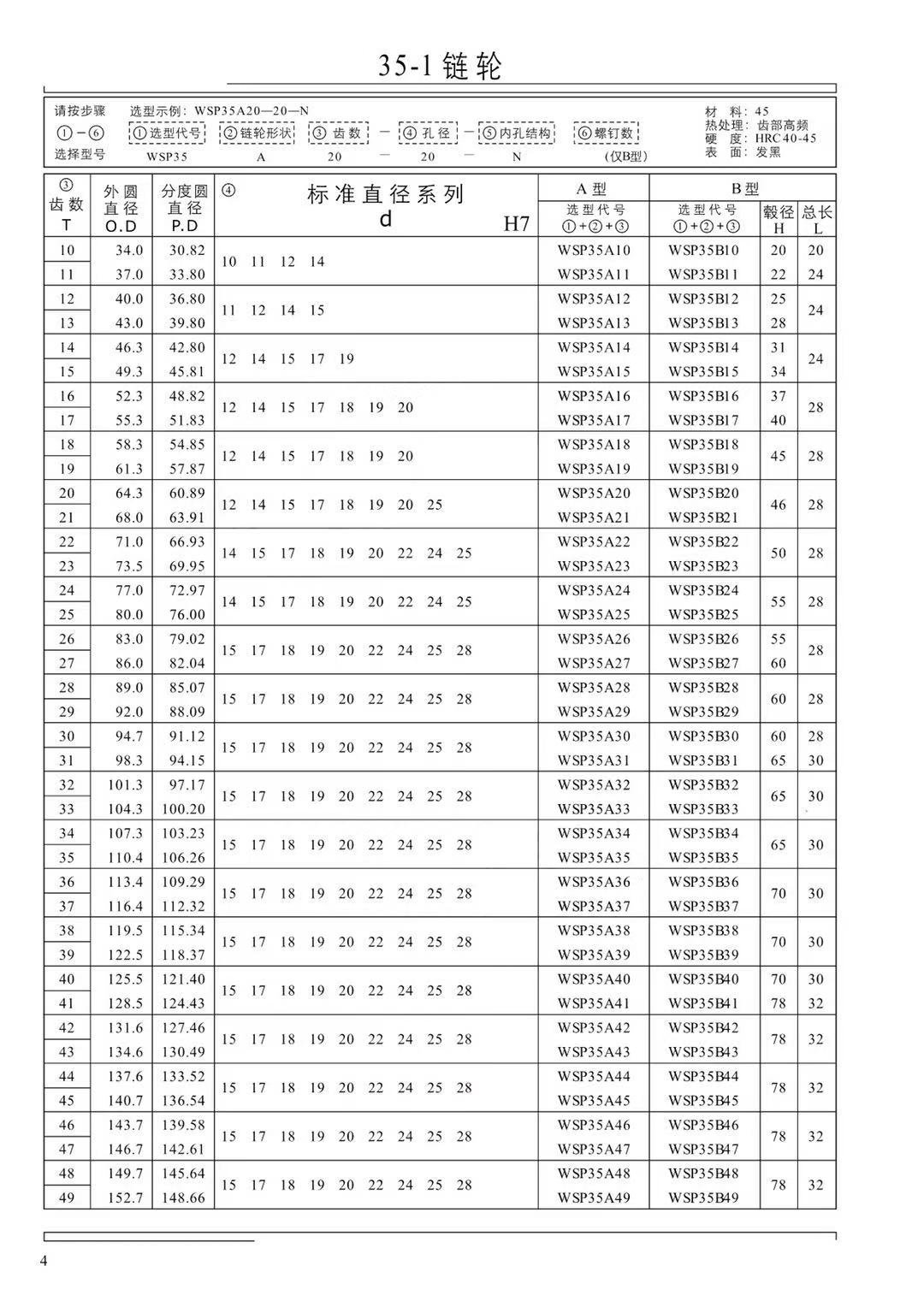

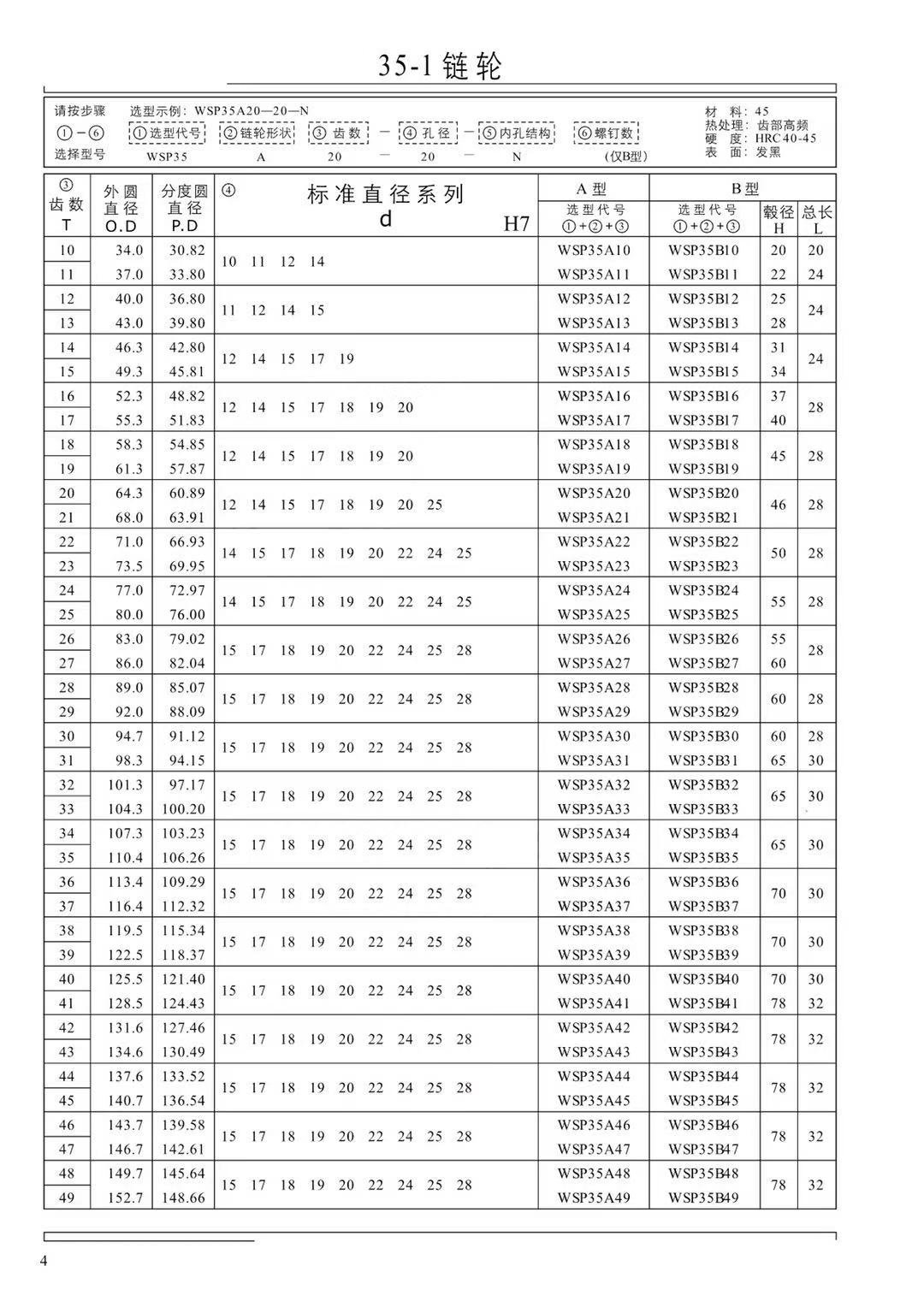

Items Show

Shell out Attention

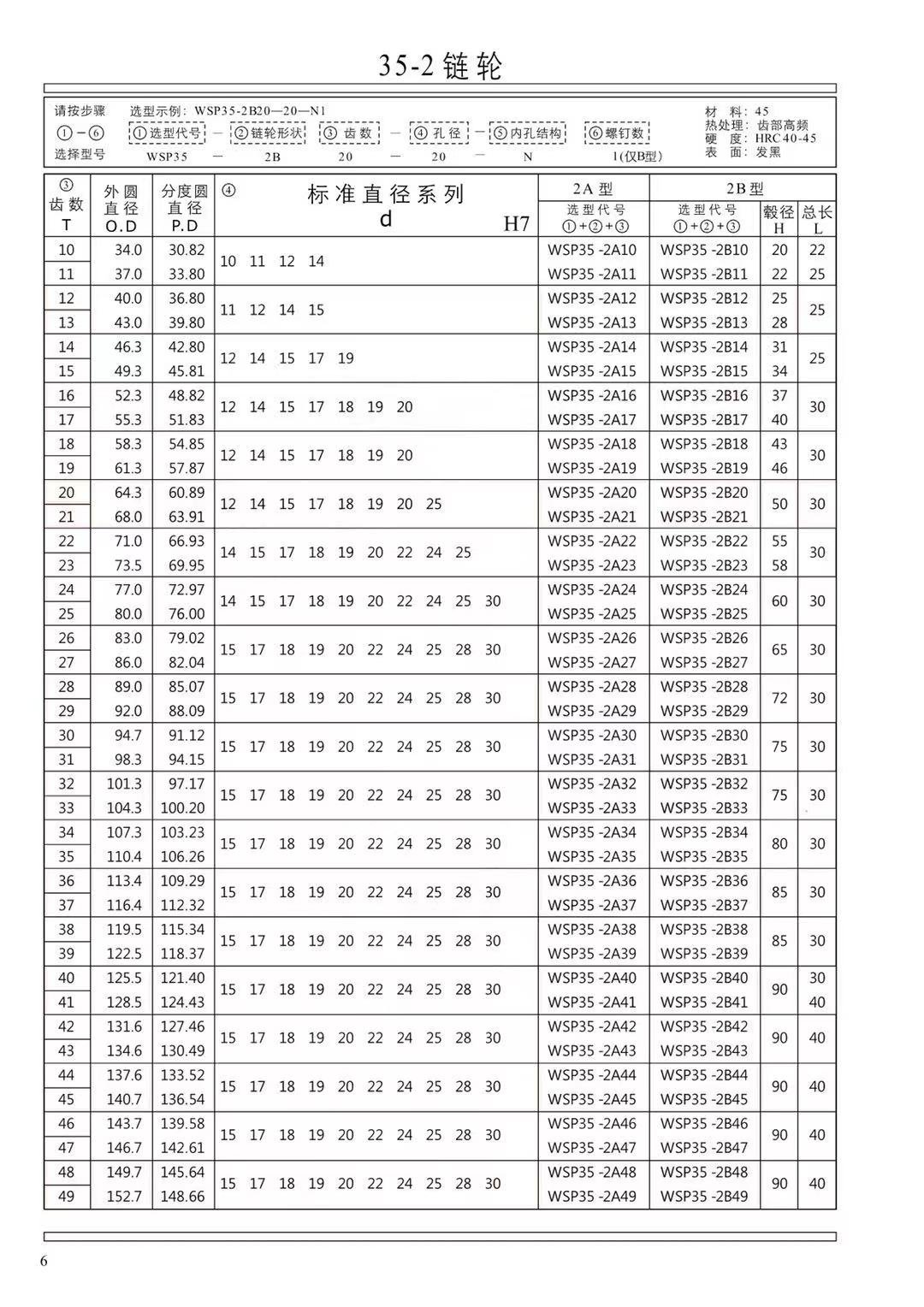

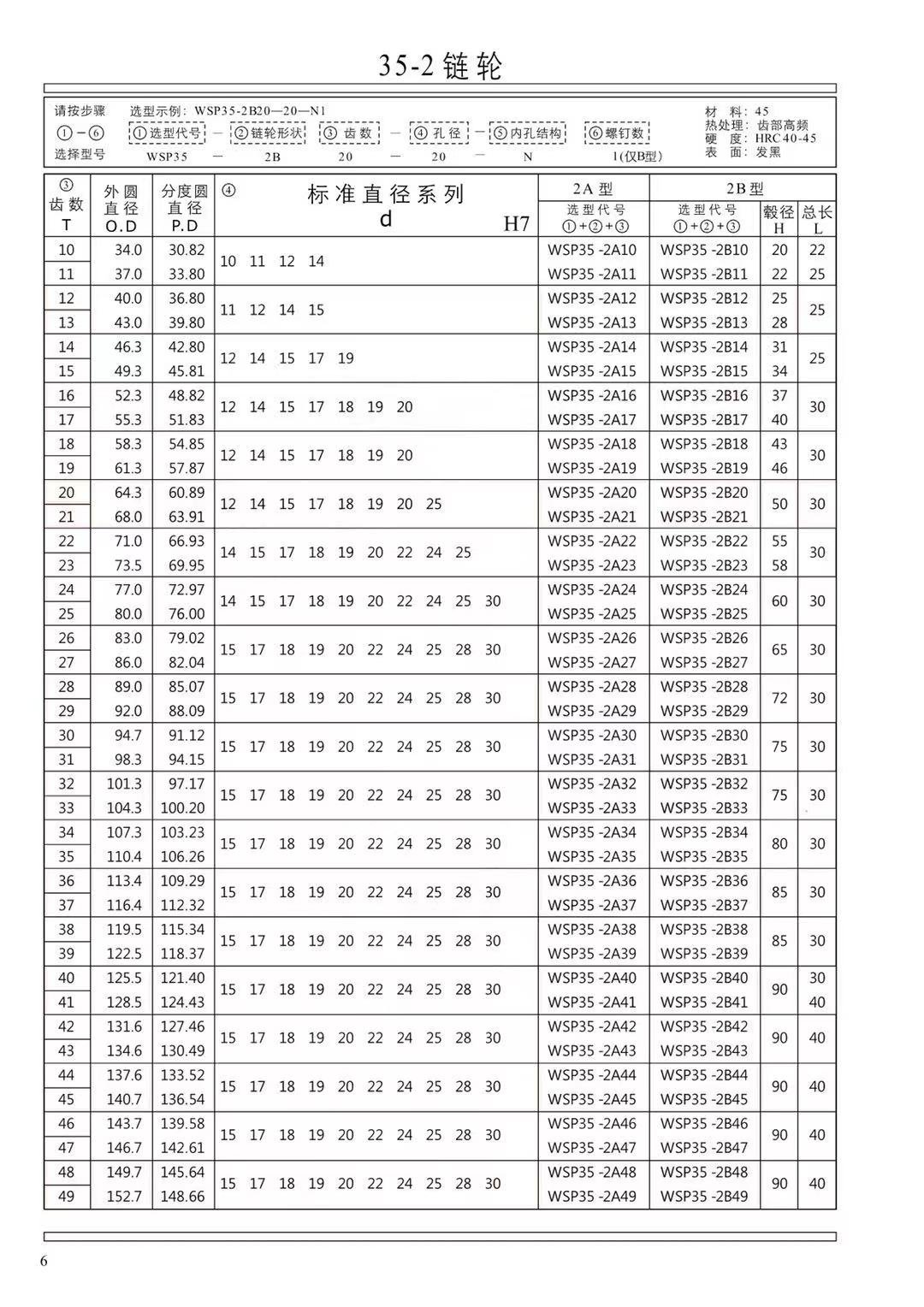

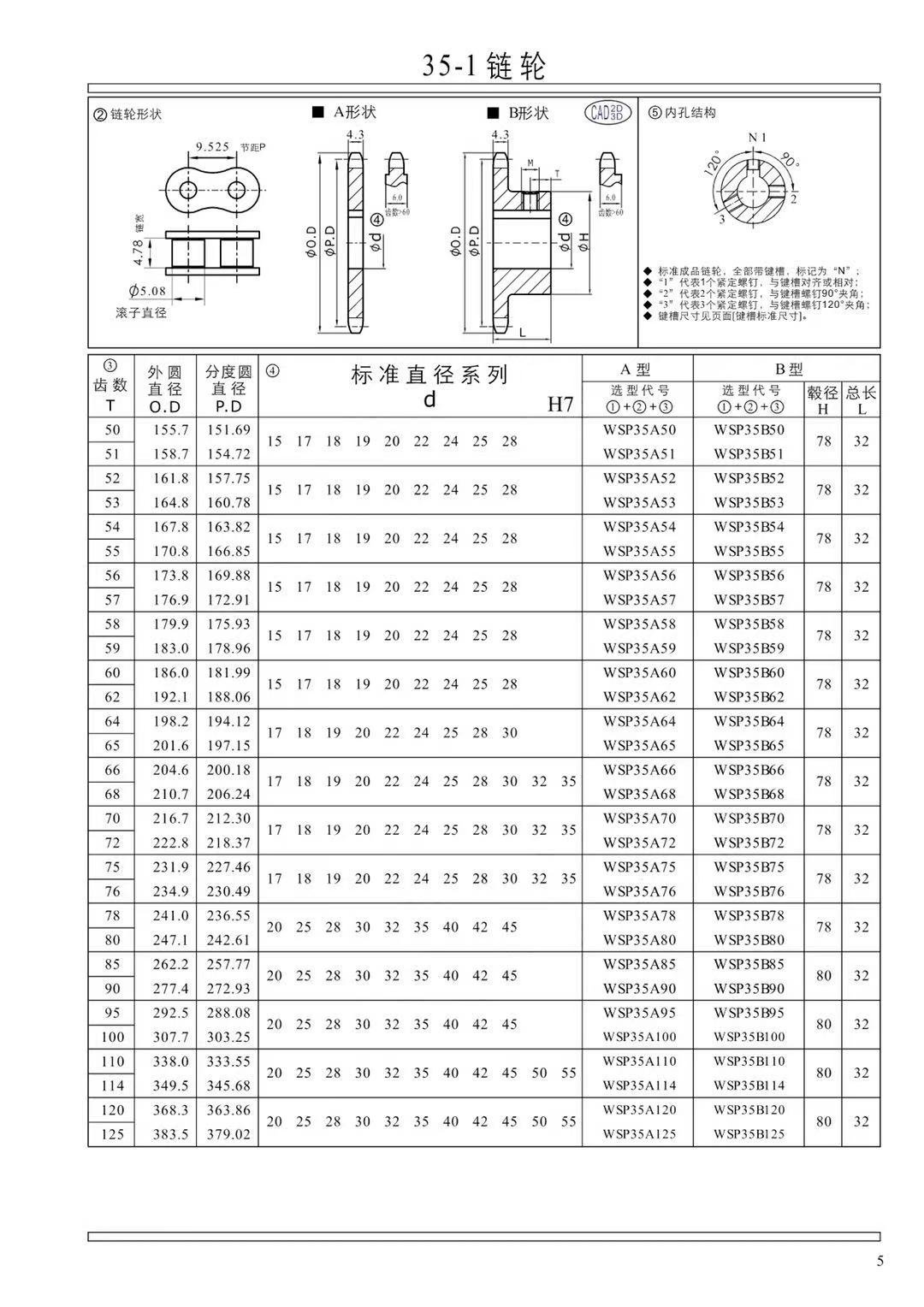

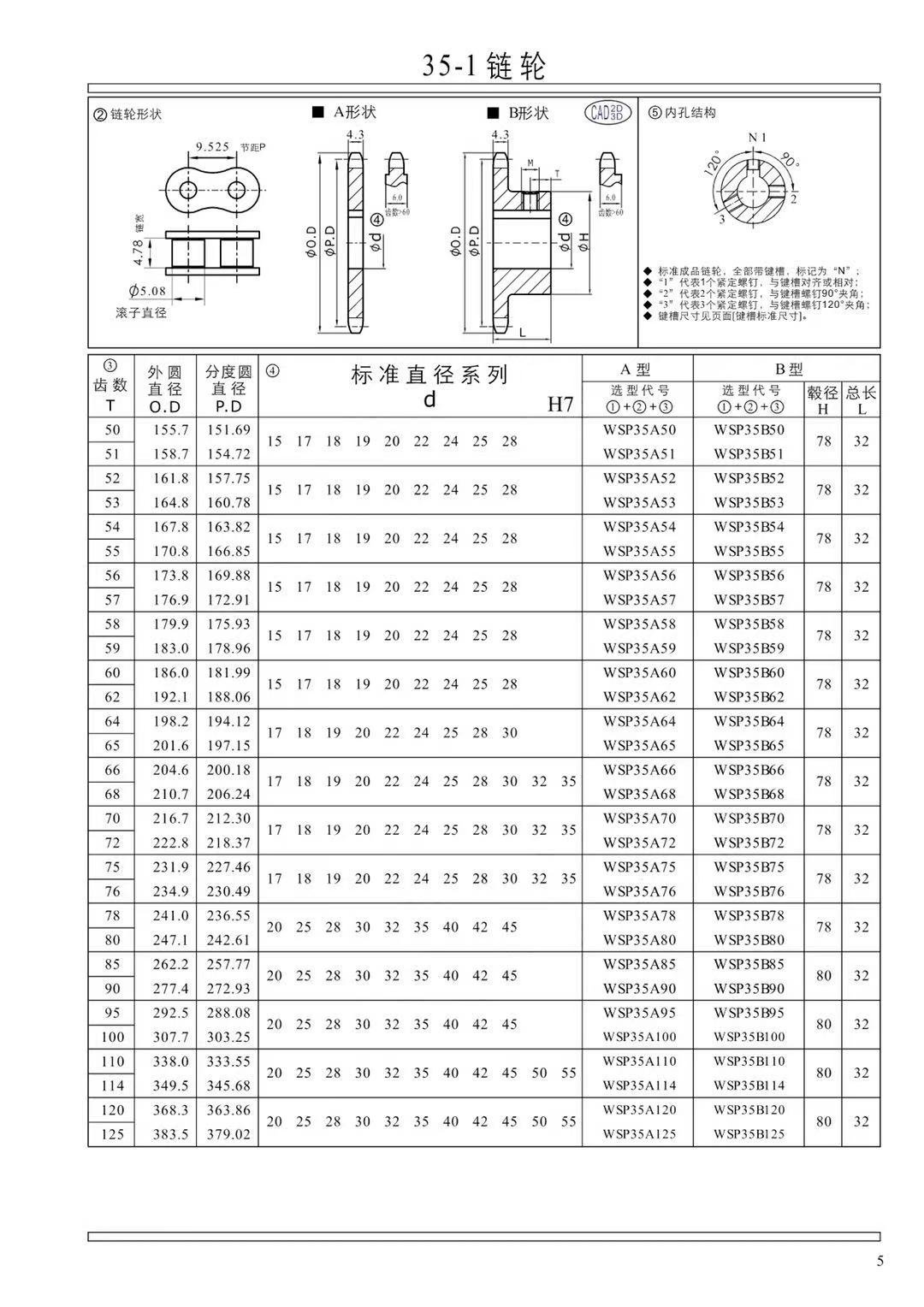

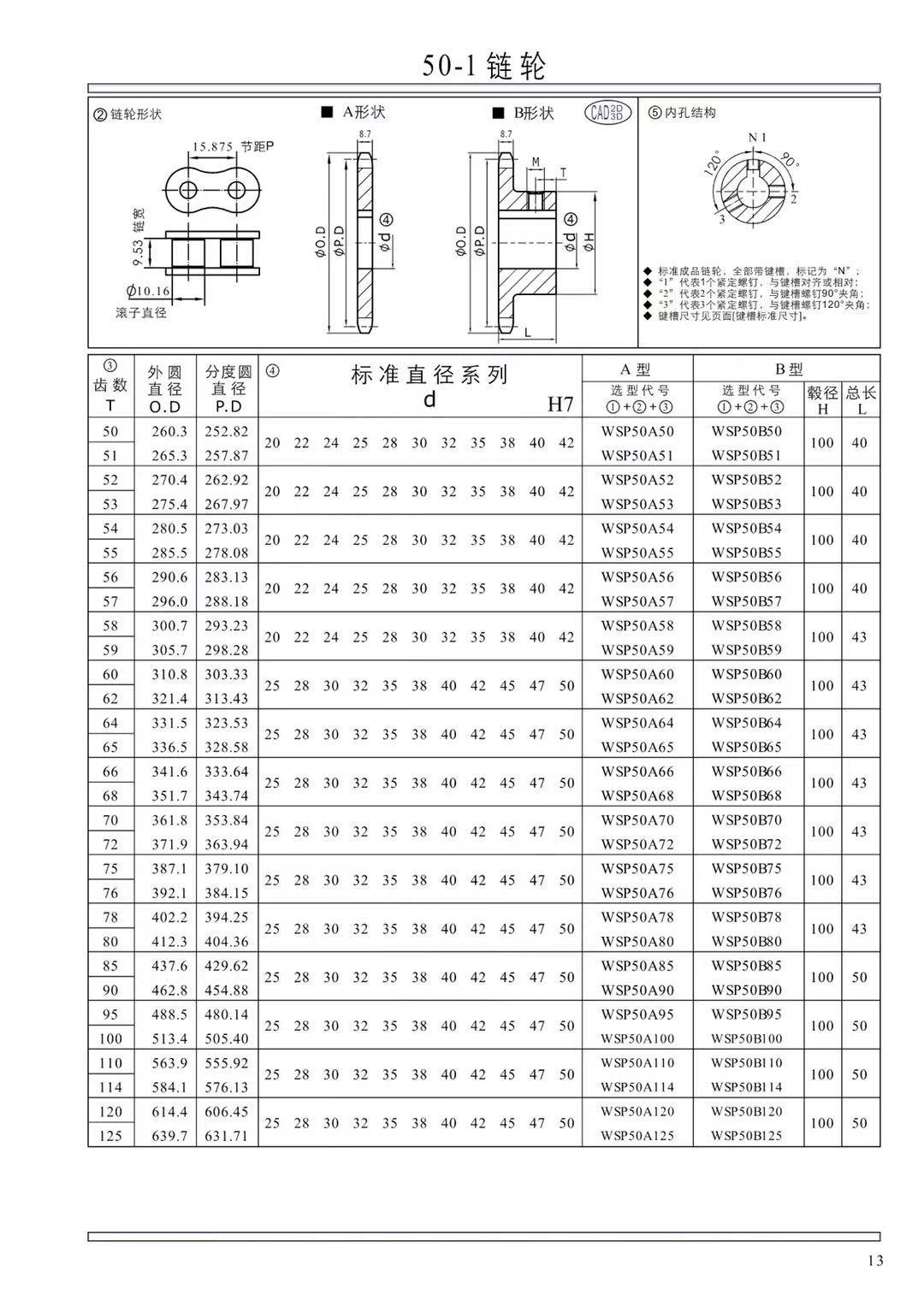

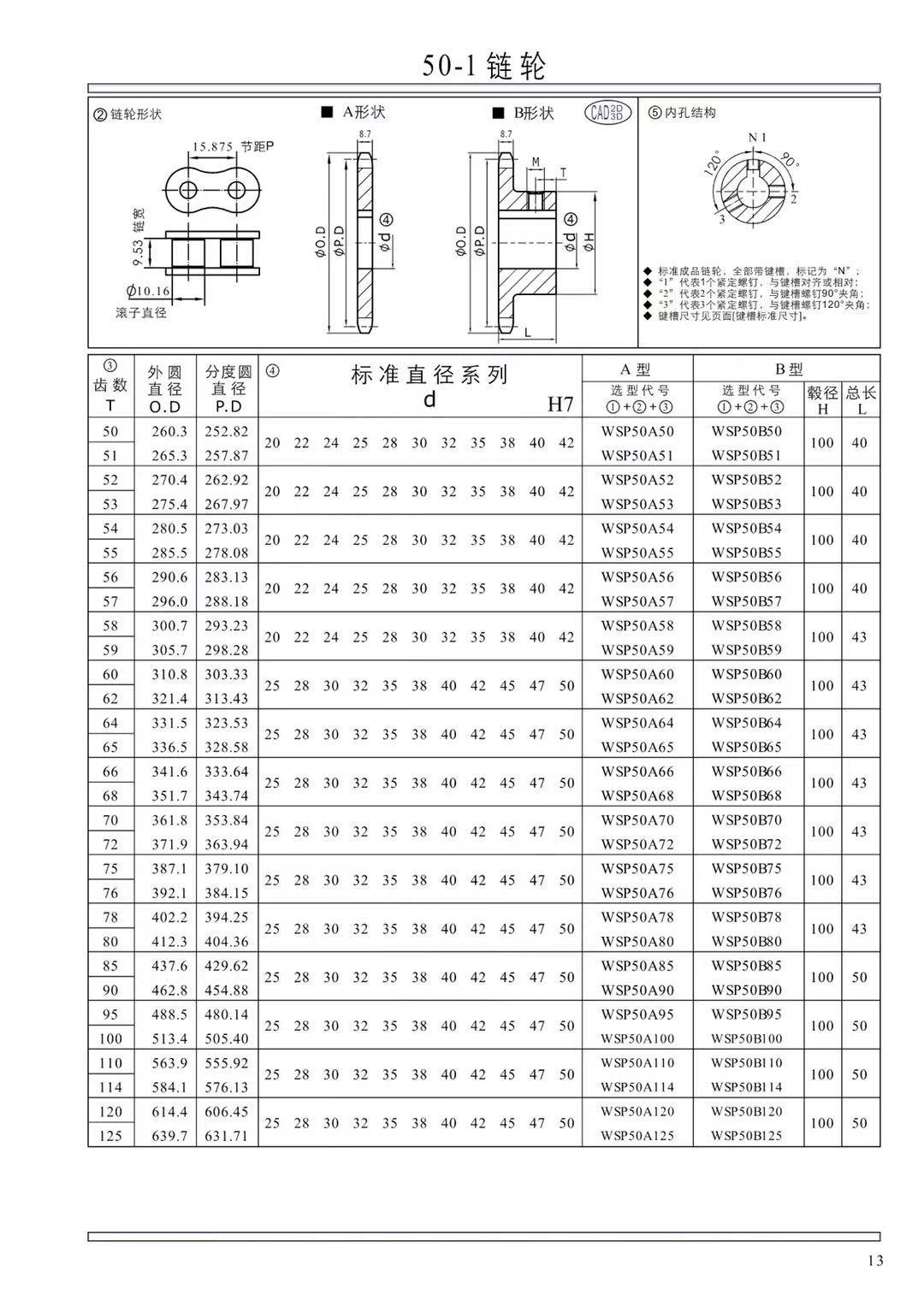

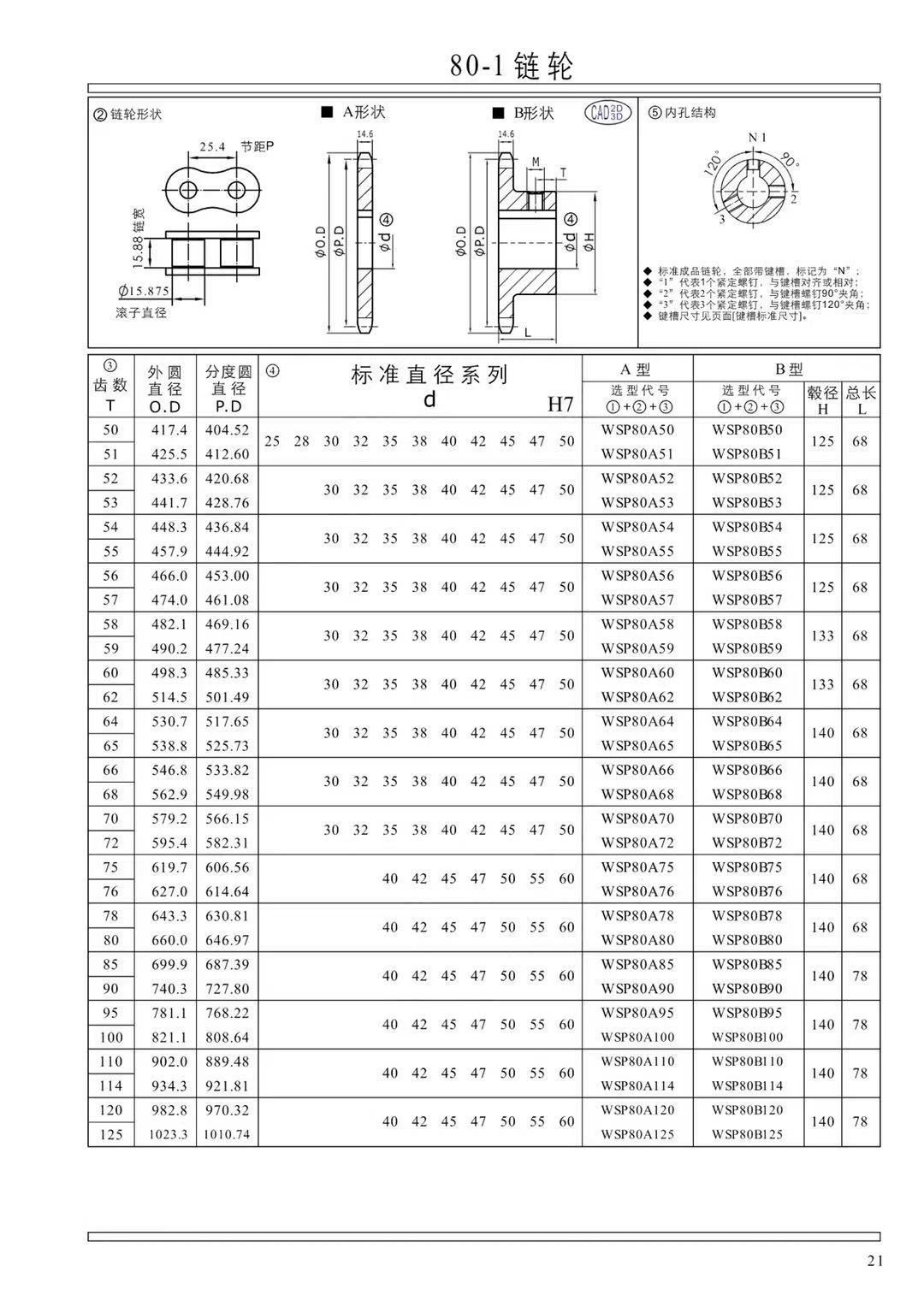

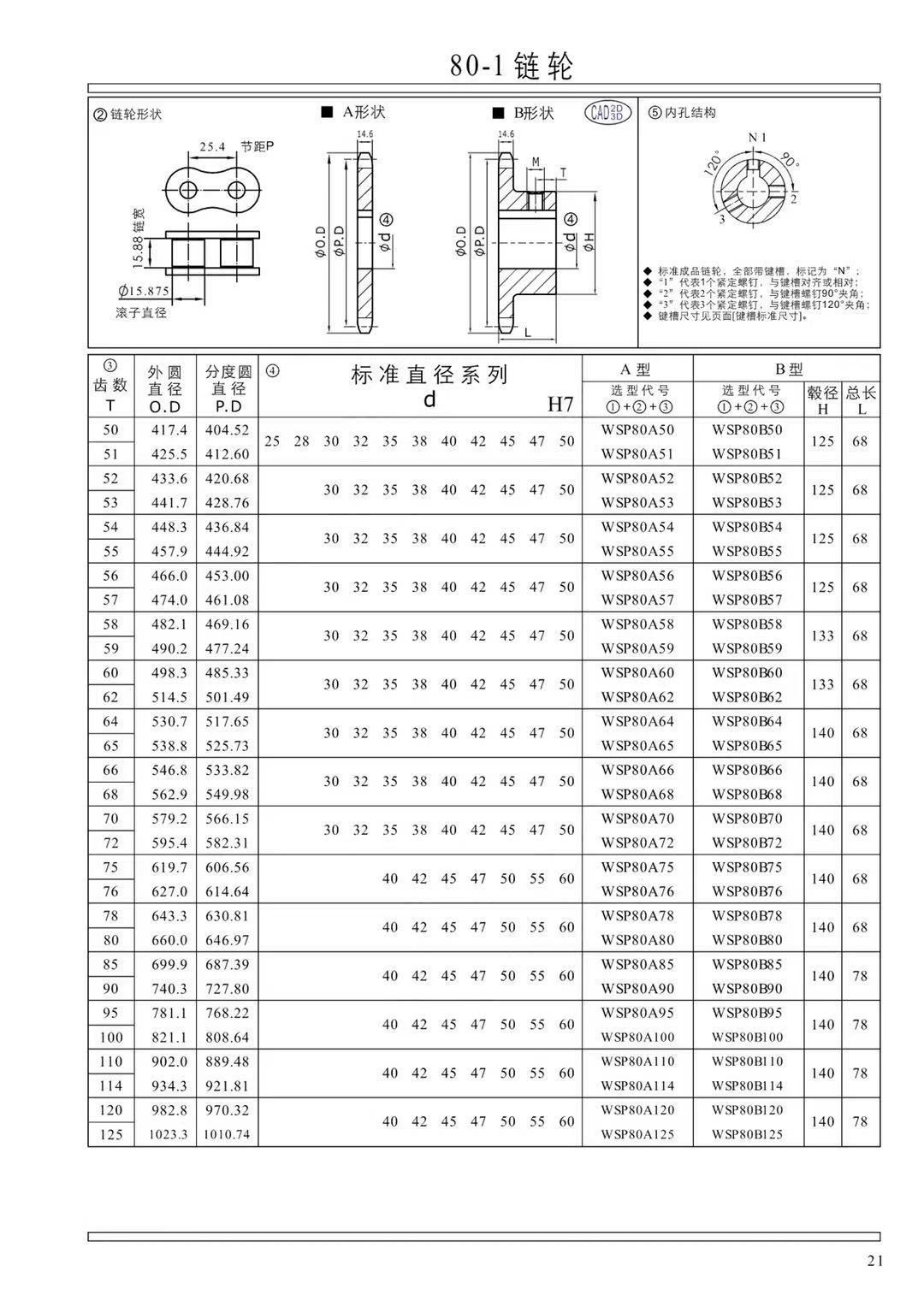

Our factory generate numerous sprockets, rack and pinion, turbine,synchronousround.umbrella. The photographs present are my factoryprocessing production . our factory has common lathe, CNC lathe, hobbing machine, slicing teeth device,drillingmachine,broaching machine . this sort of as products, our factory have inventory, 1 M, one.five M, 2 M, 3 M, 4 M, 5 M gear, 1 M, 1.five M, two M, three M, 4 M, 5 M and rack.06B, 08B, 10A, 12A, 16A, 20A, 24A, 28A common lug sprocket and flat plate sprocket.And according to the customer’s different demands can be drawn, sample processing personalized different sorts of gear, rack, sprocket, equipment ring,synchronous belt wheel, umbrella teeth, turbine worm.

The previously mentioned images are the images of the products truly processed by our manufacturing facility. If necessary, please design the merchandise in accordance to your very own products drawings or give some parameters. Our manufacturing facility can aid consumers to style the graphics.I can be personalized in accordance to buyer demand from customers sprocket, gear, rack, sprocket, umbrella tooth and other transmission products.Invoice and freight if required when inquiry.Remember to do request my sales employees.The price marked on this merchandise is not the genuine cost, our manufacturing facility wants to determine the value according to the customer’s desire and substance, as effectively as the item aperture, the dimension and quantity of screw holes, the dimensions and amount of keyway.

Packing & Delivery

Our Company

HANGZHOU epg mechanical tools co., LTD., established on May fourteen, 2015 . it is a present day high-tech company integrating research, producing and trade of transmission parts.The principal creation chain wheel, chain, gear, rack, helical gear, bevel equipment, flange, turbine worm, coupling and other mechanical transmission merchandise, items are broadly utilized in machinery, textiles,mining, foodstuff, wine, electricity, automobile and other industries – computerized chain transmission.And can undertake a assortment of non standard heterosexual sprocket structure design, manufacture.This organization selects the high top quality alloy metal and the innovative warmth therapy strategy, Utilizes the rigid scientific and technological top quality control technique, conforms to the international, the domestic normal, it has the formidable generation capability, and the first-class service through numerous a long time our factory has gained the substantial prestige in the exact same trade.Our factory has modern forging, stamping equipmentAdvanced, turning, milling, grinding, drawing, planing, producing tools and large-frequency warmth treatment gear.

Our product

All kinds of merchandise

Roller sprocket

Equipment wheel

Bevel gear

Gears rack

Other merchandise

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your supply time?

A: Generally it is 5-10 days if the merchandise are in inventory. or it is fifteen-twenty times if the merchandise are not in inventory, it is in accordance to

amount.

Q. Do you check all your items before shipping and delivery?

A: Yes, we have 100% take a look at before shipping

Q: What is your terms of payment ?

A: Payment=1000USD, thirty% T/T in progress ,balance just before shippment.

If you have one more question, pls really feel totally free to speak to us as below: