ISO 9001:2000 licensed. Stocking distributor of electricity transmission merchandise including roller & several strand roller chains. Items also consist of brakes, push components, gears, torque limiters, U-joints, pulleys, sheaves, encoders, belt drives, clutches & motors are also available.Hangzhou EPG Co.,Ltd. , was founded in November, 1997. With its five wholly owned subsidiaries.

Overview

Rapid Details

- Applicable Industries:

-

Manufacturing Plant

- Nearby Services Location:

-

None

- Application:

-

Mechanical Tools

- Surface area remedy:

-

Polishing

- Processing:

-

Turning

- Tolerance:

-

Customer’s Drawing Request

- Heat treatment method:

-

Substantial Frequency Induction Hardening

- Certification:

-

Underneath the guidance of managerial perception of “Serving agriculture, scoring a achievement via high quality of merchandise and honesty in organization”, our merchandise have been trustworthy by clients and have gained a larger share of market.

ISO9001:2009/TS 16949

- Services:

-

24 Several hours On the web

Supply Ability

- Source Capacity:

- 5000 Piece/Items per Thirty day period

Packaging & Delivery

- Packaging Details

- Neutral paper packaging,wooden boxes for outer box or according to buyer desire

- Port

- shanghai Port/Ningbo Port

-

Guide Time

: -

Amount(Parts) 1 – a thousand >1000 Est. Time(days) fifteen To be negotiated

On the internet Customization

We Ever-Electricity Group with 4 branches above 1200 employees is one of the most significant transmission components and machining items companies in China

Product Description:

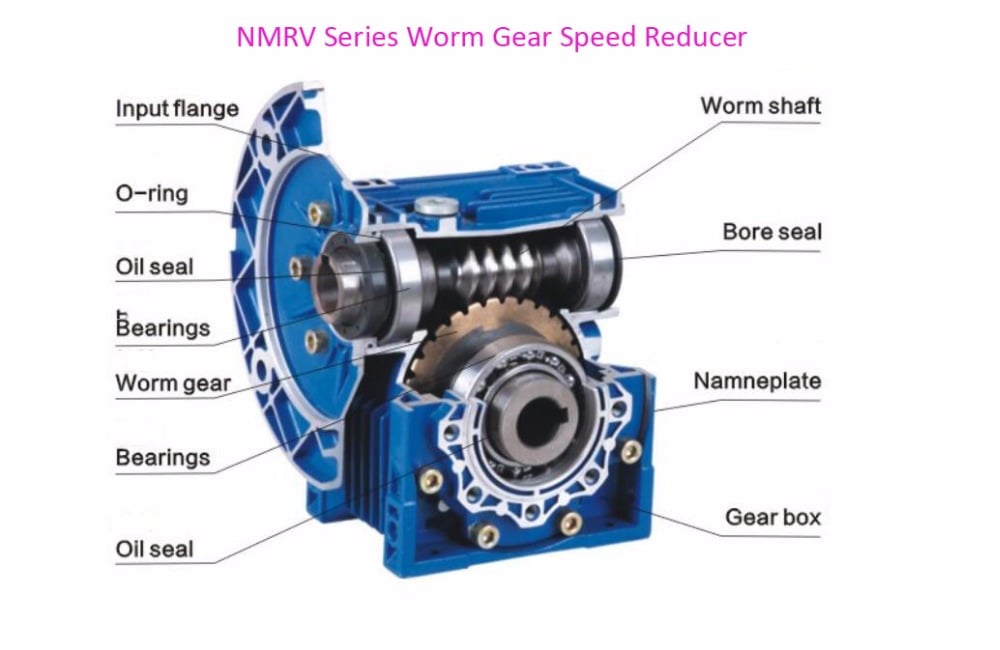

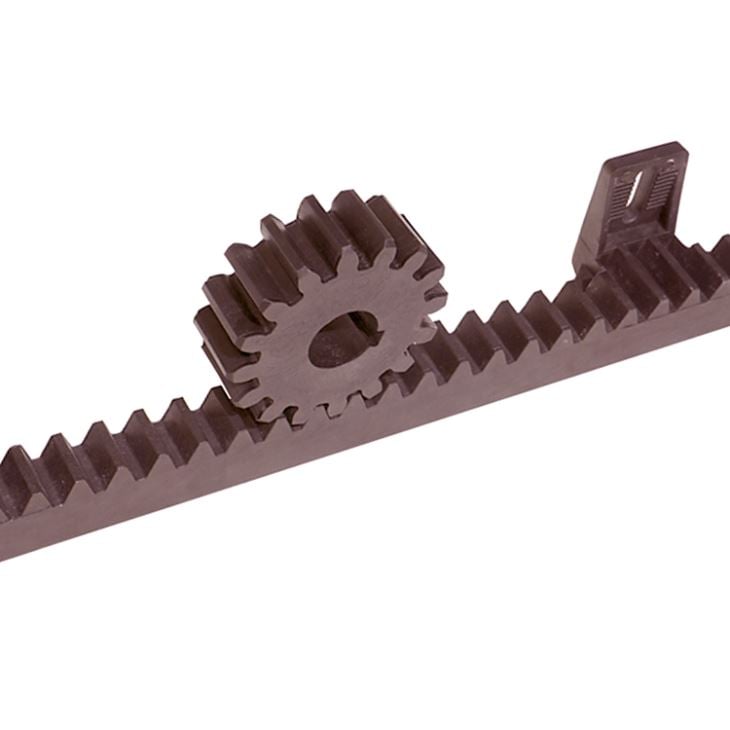

We specialized in producing auto gears , bike gears, gearbox, special vehicle (power takeoff, snowmobiles, engineering vehicles) gears, generator accessories, stainless metal ice crusher etCast Iron Gearbox: Soon after Portray with Red Antirust Paint, Paint with the Colour of RAL 5010 Gentian Blue Models: Hollow Shaft Enter with IEC-normalized Motor Flange c.

|

Material |

1020,1045,20CrMnTi, and so on. |

|

Machining Method |

Gear Hobbing , Equipment Shaping, Gear Shaving, Gear Grinding |

|

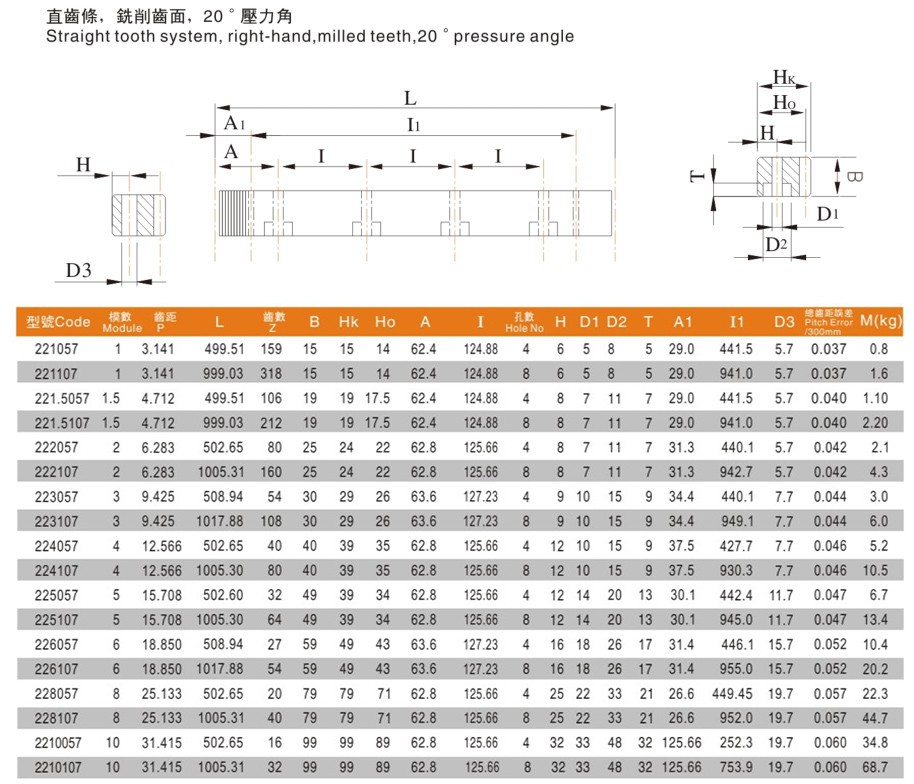

Modules |

1., 1.twenty five, 1.5, 1.seventy five, 2., 2.25, 2.5….8. and many others. |

|

Heat Remedy |

Carburizing & Quenching, Carbonitriding |

|

Normal |

DIN, ISO/GB EPG Team PTO shafts can be employed for speeds up to a thousand rpm. The greatest functioning duration of the PTO shafts varies in accordance to the measurement of the tubes The assortment of the PTO shafts of RPG Team contains 4 series , in accordance to the tube condition, AGMA, JIS,ISO/TS16949:2009 |