Product Description

| Product Name | Coupling | Place of origin | China |

| Brand | Mighty | Material | Aluminium |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Materials Used in Manufacturing Helical Couplings

Helical couplings are typically constructed from a variety of materials, chosen based on their mechanical properties and compatibility with specific applications:

- Stainless Steel: Stainless steel is a common choice due to its corrosion resistance and high strength. It is suitable for various environments, including those with exposure to moisture or chemicals.

- Aluminum: Aluminum is lightweight and offers good corrosion resistance. It’s often used in applications where weight is a concern, such as in aerospace or robotics.

- Steel Alloys: Steel alloys provide a balance between strength and cost-effectiveness. They are used in a wide range of industrial applications.

- Brass: Brass offers good corrosion resistance and is often used in applications where electrical conductivity is required.

- Plastics and Polymers: Some helical couplings are made from plastics or polymers to reduce weight and minimize electrical conductivity. These materials are often used in precision instruments and medical devices.

The choice of material depends on factors such as the intended application, environmental conditions, load requirements, and desired level of corrosion resistance. Engineers consider these factors to ensure that the selected material aligns with the performance and longevity expectations of the helical coupling.

Utilization of Helical Couplings in Mechanical Systems

A helical coupling, also known as a beam coupling, is a type of flexible coupling that is used in mechanical systems to transmit torque and motion between shafts while accommodating misalignment. Here’s how it is utilized:

Helical couplings consist of two hubs, each with helical slots that interlock with the other hub’s slots. The interlocking design allows for flexibility in multiple directions while maintaining torsional rigidity.

When utilized in mechanical systems:

- Misalignment Compensation: Helical couplings can handle angular, axial, and parallel misalignments between shafts. The helical slots provide flexibility, allowing for small amounts of misalignment without transmitting excessive stress to connected components.

- Torque Transmission: Helical couplings transmit torque from one shaft to another while minimizing backlash. The helical slot design distributes torque evenly across the coupling’s surface, ensuring efficient power transmission.

- Reduced Vibration: The helical design of the coupling helps absorb shocks and vibrations, contributing to smoother operation and reduced wear on connected components.

- Compact Design: Helical couplings have a compact and lightweight design, making them suitable for applications with limited space.

- Simple Installation: These couplings are relatively easy to install, with minimal maintenance requirements.

- Various Applications: Helical couplings are commonly used in robotics, motion control systems, CNC machines, and other applications where precision and flexibility are essential.

In summary, helical couplings provide an effective solution for transmitting torque and motion between shafts while accommodating misalignment and reducing vibrations in various mechanical systems.

Specialized Maintenance Routines for Ensuring the Longevity of Helical Couplings

To ensure the longevity of helical couplings, consider implementing specialized maintenance routines:

- Lubrication: Proper lubrication is crucial. Use the recommended lubricant and schedule regular lubrication intervals to prevent friction and wear.

- Cleaning: Regularly clean the coupling to remove dirt, debris, and contaminants that can contribute to wear.

- Inspections: Conduct thorough visual inspections to identify signs of wear, misalignment, or damage. Regular inspections allow you to address issues early.

- Alignment Checks: Periodically check and adjust the alignment of the coupling to prevent premature wear and ensure optimal power transmission.

- Fastener Tightening: Check and tighten fasteners, such as set screws or clamping elements, to prevent loosening during operation.

- Balancing: If the coupling becomes unbalanced, have it balanced to prevent vibrations and reduce wear.

- Temperature Monitoring: Monitor the operating temperature of the coupling area. Abnormal temperature increases can indicate issues.

- Vibration Analysis: Use vibration analysis tools to monitor coupling vibrations and identify any unusual patterns.

- Replacement of Worn Parts: Replace worn or damaged parts promptly with genuine replacement components from the manufacturer.

- Record Keeping: Maintain a detailed maintenance record, including inspection dates, maintenance activities, and any issues identified.

- Training: Train maintenance personnel on proper maintenance procedures and techniques specific to helical couplings.

By following these specialized maintenance routines, you can maximize the longevity and performance of helical couplings in your machinery systems.

editor by CX 2024-05-07

China Professional Best Price Mighty Wholesale High Speed Aluminum Helical Flexible Beam Shaft Coupling

Product Description

| Product Name | Coupling | Place of origin | China |

| Brand | Mighty | Material | Aluminium |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Challenges Arising from Misaligned Helical Couplings and Their Resolution

Misaligned helical couplings can lead to several challenges that affect the performance and longevity of machinery:

- Reduced Torque Transmission: Angular misalignment in helical couplings can result in reduced torque transmission efficiency, leading to power loss and decreased overall machinery performance.

- Excessive Wear: Continuous operation with misaligned couplings can cause increased wear on both the coupling and connected components, resulting in premature failure and the need for frequent maintenance.

- Vibration and Noise: Misaligned couplings can generate vibration and noise due to uneven torque distribution and irregular motion, negatively impacting machinery operation and operator comfort.

- Heat Generation: Misalignment can lead to increased friction and heat generation at the coupling interface, potentially causing damage to the coupling material and affecting surrounding components.

To address these challenges, it’s crucial to:

- Regularly Inspect and Align: Perform routine inspections to identify any misalignment issues. If misalignment is detected, realign the couplings to ensure proper shaft alignment.

- Use Flexible Couplings: Choose helical couplings specifically designed to accommodate misalignment. These couplings provide flexibility and self-alignment features, reducing the impact of misalignment.

- Implement Precision Installation: During installation, carefully align the shafts using precision tools and techniques. Avoid forceful installation that could introduce misalignment.

- Monitor Operating Conditions: Regularly monitor machinery operation to detect any abnormal vibration, noise, or performance changes that could indicate misalignment issues.

By addressing misalignment challenges promptly and following best practices, you can ensure the proper functioning and longevity of helical couplings and the machinery they are installed in.

Utilization of Helical Couplings in Mechanical Systems

A helical coupling, also known as a beam coupling, is a type of flexible coupling that is used in mechanical systems to transmit torque and motion between shafts while accommodating misalignment. Here’s how it is utilized:

Helical couplings consist of two hubs, each with helical slots that interlock with the other hub’s slots. The interlocking design allows for flexibility in multiple directions while maintaining torsional rigidity.

When utilized in mechanical systems:

- Misalignment Compensation: Helical couplings can handle angular, axial, and parallel misalignments between shafts. The helical slots provide flexibility, allowing for small amounts of misalignment without transmitting excessive stress to connected components.

- Torque Transmission: Helical couplings transmit torque from one shaft to another while minimizing backlash. The helical slot design distributes torque evenly across the coupling’s surface, ensuring efficient power transmission.

- Reduced Vibration: The helical design of the coupling helps absorb shocks and vibrations, contributing to smoother operation and reduced wear on connected components.

- Compact Design: Helical couplings have a compact and lightweight design, making them suitable for applications with limited space.

- Simple Installation: These couplings are relatively easy to install, with minimal maintenance requirements.

- Various Applications: Helical couplings are commonly used in robotics, motion control systems, CNC machines, and other applications where precision and flexibility are essential.

In summary, helical couplings provide an effective solution for transmitting torque and motion between shafts while accommodating misalignment and reducing vibrations in various mechanical systems.

Best Practices for Lubricating and Preserving the Performance of Helical Couplings

Lubrication is crucial for maintaining the performance and longevity of helical couplings. Here are some best practices to consider:

- Choose the Right Lubricant: Select a lubricant that is compatible with the materials of the coupling and provides adequate protection against wear and corrosion.

- Regular Lubrication: Follow the manufacturer’s guidelines for lubrication intervals. Regularly lubricate the coupling to ensure proper operation and prevent excessive wear.

- Clean Before Lubrication: Clean the coupling and the surrounding area before applying lubricant to prevent contamination.

- Apply the Right Amount: Apply the appropriate amount of lubricant as recommended by the manufacturer. Too much lubricant can lead to excess buildup and attract debris.

- Distribute Evenly: Ensure that the lubricant is evenly distributed across the coupling’s surfaces to provide effective lubrication.

- Monitor Performance: Regularly monitor the coupling’s performance for any signs of increased friction or abnormal operation that may indicate the need for relubrication.

- Inspect for Wear: During maintenance checks, inspect the coupling for signs of wear, corrosion, or damage. Replace the coupling if necessary.

- Protect Against Contaminants: Shield the coupling from dust, dirt, and other contaminants that can degrade the lubricant and cause premature wear.

- Environmental Considerations: If the machinery operates in extreme temperatures, wet or corrosive environments, choose a lubricant that can withstand these conditions.

- Follow Manufacturer’s Recommendations: Always follow the manufacturer’s recommendations for lubrication, maintenance, and storage to ensure optimal coupling performance.

By adhering to these best practices, you can maximize the efficiency, reliability, and lifespan of helical couplings in various mechanical systems.

editor by CX 2024-04-24

China Standard Best Price Mighty Wholesale High Speed Aluminum Helical Flexible Beam Shaft Coupling

Product Description

| Product Name | Coupling | Place of origin | China |

| Brand | Mighty | Material | Aluminium |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Materials Used in Manufacturing Helical Couplings

Helical couplings are typically constructed from a variety of materials, chosen based on their mechanical properties and compatibility with specific applications:

- Stainless Steel: Stainless steel is a common choice due to its corrosion resistance and high strength. It is suitable for various environments, including those with exposure to moisture or chemicals.

- Aluminum: Aluminum is lightweight and offers good corrosion resistance. It’s often used in applications where weight is a concern, such as in aerospace or robotics.

- Steel Alloys: Steel alloys provide a balance between strength and cost-effectiveness. They are used in a wide range of industrial applications.

- Brass: Brass offers good corrosion resistance and is often used in applications where electrical conductivity is required.

- Plastics and Polymers: Some helical couplings are made from plastics or polymers to reduce weight and minimize electrical conductivity. These materials are often used in precision instruments and medical devices.

The choice of material depends on factors such as the intended application, environmental conditions, load requirements, and desired level of corrosion resistance. Engineers consider these factors to ensure that the selected material aligns with the performance and longevity expectations of the helical coupling.

Advantages of Using Helical Couplings in Industrial Applications

Helical couplings offer several key advantages when used in industrial applications:

- Misalignment Compensation: Helical couplings can accommodate angular, axial, and parallel misalignments between shafts, helping to extend the lifespan of connected components and reducing the risk of premature failure.

- High Torque Transmission: These couplings are designed to transmit high levels of torque between shafts, making them suitable for applications that require efficient power transmission.

- Backlash Reduction: The helical design minimizes backlash, ensuring accurate positioning and motion control in precision applications.

- Shock and Vibration Absorption: Helical couplings absorb shocks and vibrations, protecting connected equipment from excessive wear and minimizing noise in the system.

- Compact and Lightweight: The compact and lightweight design of helical couplings makes them ideal for applications with limited space and weight constraints.

- Easy Installation: Helical couplings are relatively simple to install, requiring minimal tools and expertise.

- Corrosion Resistance: Many helical couplings are made from materials that offer corrosion resistance, making them suitable for various environmental conditions.

- Cost-Effective: Helical couplings provide a cost-effective solution for flexible shaft connections, reducing the need for complex and expensive alignment procedures.

- Long Service Life: Properly installed and maintained helical couplings can have a long service life, contributing to the reliability of the overall system.

Overall, helical couplings are a versatile and reliable choice for industrial applications that require torque transmission, misalignment compensation, and vibration reduction.

Best Practices for Lubricating and Preserving the Performance of Helical Couplings

Lubrication is crucial for maintaining the performance and longevity of helical couplings. Here are some best practices to consider:

- Choose the Right Lubricant: Select a lubricant that is compatible with the materials of the coupling and provides adequate protection against wear and corrosion.

- Regular Lubrication: Follow the manufacturer’s guidelines for lubrication intervals. Regularly lubricate the coupling to ensure proper operation and prevent excessive wear.

- Clean Before Lubrication: Clean the coupling and the surrounding area before applying lubricant to prevent contamination.

- Apply the Right Amount: Apply the appropriate amount of lubricant as recommended by the manufacturer. Too much lubricant can lead to excess buildup and attract debris.

- Distribute Evenly: Ensure that the lubricant is evenly distributed across the coupling’s surfaces to provide effective lubrication.

- Monitor Performance: Regularly monitor the coupling’s performance for any signs of increased friction or abnormal operation that may indicate the need for relubrication.

- Inspect for Wear: During maintenance checks, inspect the coupling for signs of wear, corrosion, or damage. Replace the coupling if necessary.

- Protect Against Contaminants: Shield the coupling from dust, dirt, and other contaminants that can degrade the lubricant and cause premature wear.

- Environmental Considerations: If the machinery operates in extreme temperatures, wet or corrosive environments, choose a lubricant that can withstand these conditions.

- Follow Manufacturer’s Recommendations: Always follow the manufacturer’s recommendations for lubrication, maintenance, and storage to ensure optimal coupling performance.

By adhering to these best practices, you can maximize the efficiency, reliability, and lifespan of helical couplings in various mechanical systems.

editor by CX 2024-04-12

China Best Sales Best Price Mighty Wholesale High Speed Aluminum Helical Flexible Beam Shaft Coupling

Product Description

| Product Name | Coupling | Place of origin | China |

| Brand | Mighty | Material | Aluminium |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Comparison of Helical Couplings with Beam Couplings and Oldham Couplings

Helical couplings, beam couplings, and Oldham couplings are all flexible coupling types used in mechanical systems, but they differ in design and characteristics:

- Helical Couplings: Helical couplings offer high torque transmission, axial flexibility, and some angular misalignment compensation. They are known for their helical-cut grooves that provide flexibility and compensate for misalignment, making them suitable for applications with moderate misalignment.

- Beam Couplings: Beam couplings consist of one or more flexible beams that provide radial flexibility and angular misalignment compensation. They excel in applications requiring high precision and low torque. However, they have limitations in transmitting high torque and axial misalignment.

- Oldham Couplings: Oldham couplings use two hubs and a center disc to transmit torque while accommodating angular misalignment. They offer higher torsional stiffness compared to helical and beam couplings. Oldham couplings are suitable for applications with moderate torque transmission and angular misalignment.

When comparing these coupling types:

- Helical couplings are preferred for applications with moderate torque, axial flexibility, and moderate angular misalignment.

- Beam couplings are chosen for applications requiring precision motion, low torque, and minimal angular misalignment.

- Oldham couplings are used when higher torsional stiffness and moderate angular misalignment compensation are needed.

The choice depends on factors such as torque requirements, misalignment, precision, and the specific needs of the application. Each coupling type offers unique benefits and limitations, allowing engineers to select the most suitable coupling for their machinery systems.

Considerations for Choosing a Helical Coupling for Your Application

When selecting a helical coupling for a specific application, several key factors should be considered:

- Torque Capacity: Determine the maximum torque that the coupling will need to transmit in your application. Choose a coupling with a torque capacity that exceeds the application’s requirements.

- Shaft Size: Ensure that the coupling’s bore size matches the diameter of the shafts to be connected. Proper sizing prevents slippage and ensures efficient torque transmission.

- Angular Misalignment: Evaluate the degree of angular misalignment that the coupling needs to accommodate. Different couplings have varying angular misalignment capabilities.

- Radial Misalignment: Consider the amount of radial misalignment that the coupling must handle. Choose a coupling that can accommodate the expected radial displacement.

- Axial Misalignment: If there will be axial movement between the shafts, select a coupling that can handle the required axial displacement without binding.

- Environmental Conditions: Take into account the operating environment, including temperature, humidity, dust, and chemical exposure. Choose a coupling material that is suitable for the conditions.

- Speed: Determine the rotational speed of the shafts. Ensure that the chosen coupling is rated for the application’s speed without causing resonance or vibration issues.

- Backlash: Assess the acceptable level of backlash in your application. Some couplings have minimal backlash, which is critical for precision applications.

- Cost: Consider the budget for your project. While it’s important to choose a reliable coupling, also balance the cost with the performance requirements.

By carefully evaluating these factors and consulting with coupling manufacturers or experts, you can choose the right helical coupling that meets the needs of your specific application.

Best Practices for Lubricating and Preserving the Performance of Helical Couplings

Lubrication is crucial for maintaining the performance and longevity of helical couplings. Here are some best practices to consider:

- Choose the Right Lubricant: Select a lubricant that is compatible with the materials of the coupling and provides adequate protection against wear and corrosion.

- Regular Lubrication: Follow the manufacturer’s guidelines for lubrication intervals. Regularly lubricate the coupling to ensure proper operation and prevent excessive wear.

- Clean Before Lubrication: Clean the coupling and the surrounding area before applying lubricant to prevent contamination.

- Apply the Right Amount: Apply the appropriate amount of lubricant as recommended by the manufacturer. Too much lubricant can lead to excess buildup and attract debris.

- Distribute Evenly: Ensure that the lubricant is evenly distributed across the coupling’s surfaces to provide effective lubrication.

- Monitor Performance: Regularly monitor the coupling’s performance for any signs of increased friction or abnormal operation that may indicate the need for relubrication.

- Inspect for Wear: During maintenance checks, inspect the coupling for signs of wear, corrosion, or damage. Replace the coupling if necessary.

- Protect Against Contaminants: Shield the coupling from dust, dirt, and other contaminants that can degrade the lubricant and cause premature wear.

- Environmental Considerations: If the machinery operates in extreme temperatures, wet or corrosive environments, choose a lubricant that can withstand these conditions.

- Follow Manufacturer’s Recommendations: Always follow the manufacturer’s recommendations for lubrication, maintenance, and storage to ensure optimal coupling performance.

By adhering to these best practices, you can maximize the efficiency, reliability, and lifespan of helical couplings in various mechanical systems.

editor by CX 2024-04-02

China best Best Price Mighty Wholesale High Speed Aluminum Helical Flexible Beam Shaft Coupling

Product Description

| Product Name | Coupling | Place of origin | China |

| Brand | Mighty | Material | Aluminium |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Endurance of Helical Couplings for High Torque and Axial Motion

Helical couplings are designed to withstand a range of mechanical forces, including high levels of torque and axial motion:

- High Torque: Helical couplings are capable of transmitting high levels of torque due to their robust construction and the interlocking helical teeth. The helical design enhances the coupling’s ability to handle torque without compromising flexibility.

- Axial Motion: Helical couplings can accommodate limited axial motion without compromising their performance. This is especially beneficial in applications where shafts might experience slight axial displacement due to thermal expansion or other factors.

Engineers select helical couplings based on the anticipated torque requirements and axial motion characteristics of the application. It’s important to ensure that the selected coupling has the necessary torque rating and axial flexibility to meet the demands of the specific machinery or system.

Variations of Helical Couplings for Specific Uses

Helical couplings come in various variations, each designed to suit specific applications and requirements:

- Flexible Helical Couplings: These couplings are designed to provide flexibility to accommodate misalignments and torsional vibrations. They are commonly used in applications where shaft misalignment is expected.

- Rigid Helical Couplings: Rigid helical couplings are designed to provide a more solid connection between shafts, offering minimal flexibility. They are suitable for applications where precise torque transmission and accurate positioning are crucial.

- Beam Helical Couplings: Beam-style helical couplings use thin metal beams to transmit torque while allowing for some misalignment. They are often used in applications that require high torsional stiffness and minimal backlash.

- Bellows Helical Couplings: Bellows couplings use accordion-like bellows to compensate for misalignment and provide vibration damping. They are commonly used in applications that require high torsional flexibility and protection from external contaminants.

- Oldham Helical Couplings: Oldham couplings use three discs: a central disc sandwiched between two outer discs with perpendicular slots. They offer excellent misalignment compensation and are often used in motion control systems.

- Helical-Beam Couplings: These couplings combine the flexibility of beam couplings with the misalignment compensation of helical couplings. They are suitable for applications that require both flexibility and misalignment tolerance.

- Slit Helical Couplings: Slit couplings have a slit design that allows for easy installation and removal without the need to disassemble the entire system. They are commonly used in applications where frequent maintenance is required.

The availability of these variations allows engineers and designers to select the most suitable type of helical coupling based on the specific needs of their application.

Elaboration on Torsional Stiffness in Relation to Helical Couplings and Its Significance

Torsional stiffness refers to the resistance of a helical coupling to twisting or rotational deformation under a certain amount of torque. It is a crucial mechanical property that impacts the performance of helical couplings:

- Response to Torque: A coupling with higher torsional stiffness can transmit torque more efficiently and accurately, resulting in better power transmission.

- Reduced Torsional Deflection: High torsional stiffness minimizes torsional deflection, which is the angular twist experienced by the coupling under torque. This is especially important in precision applications where accurate angular positioning is required.

- Minimized Backlash: Torsional stiffness helps reduce backlash, which is the angular play or movement between connected shafts when the direction of torque changes.

- Dynamic Performance: Torsional stiffness contributes to the coupling’s ability to respond quickly to changes in torque, making it suitable for applications with rapidly changing loads.

- Vibration Damping: While helical couplings provide some level of flexibility to accommodate misalignment, their torsional stiffness helps dampen vibrations and resonances.

- Torsional Resonances: In applications where torsional resonances can occur, a well-matched torsional stiffness can help avoid critical speeds and potential mechanical failures.

When selecting a helical coupling, considering its torsional stiffness in relation to the application’s torque requirements and performance demands is essential to ensure optimal functionality and durability.

editor by CX 2024-03-27

China OEM Transmission Parts Flexible Shaft Rubber Coupling Cast Iron Rn Coupling Rnb-110 for Connect Motor with Factory Price a fluid coupling

Product Description

Product Description

We are the leading top Chinese coupling manufacturer, and are specializing in various high quality RN coupling.

KASIN RN Shaft Couplings

1. Material:the hub of the Couplings is Cast Iron,the Elastomer is Rubber.

2. OEM and ODM are available

3. High efficient in transmission

4. Finishing:The surface treatment is normally Phosphated and painting

5. High quality with competitive price

6. Different models suitable for your different demands

7. Stock for different bore size on both sides available.

8. Application in wide range of environment.

9. Quick and easy mounting and disassembly.

10. Resistant to oil and electrical insulation.

11. Identical clockwise and anticlockwise rotational characteristics.

12. Small dimension, low weight, high transmitted torque.

13. It has good performance on compensating the misalignment.

14.Feature of couplings:free of maintenance,simple structure and easy to install.

15.Application:Mainly used in the mining, metallurgical, cement, chemicals, construction, building materials, electric power, telecommunications, textiles, and transportation departments.

Techncial Date

Related Products

Roller Chain Coupling FCL Coupling Curved Jaw Coupling

Manufacturing

Applications:

RN couplings are offered in the industry’s largest variety of stock bore/keyway combinations. These couplings require no lubrication and provide highly reliable service for light, medium, and heavy duty electrical motor and internal combustion power transmission applications. Applications include power transmission to industrial equipment such as pumps, gear boxes, compressors, blowers, mixers, and conveyors.

About Us

Kasin group was established in 1989, and its first product is casting carrier trolley for power & free conveyor system. In 1995, CZPT purchased HangZhou Guoping Forging Factory (LYGP), a marketer of forging bolts & nuts to power & free line market in china. With this acquisition, CZPT positioned itself as 1 of major parts suppliers of monorail and power & free conveyor system in china.

In 2/8822 0571 -57152031 Fax: 86~/8822 0571 -57152030

Http://kasinchain

| Standard Or Nonstandard: | Standard |

|---|---|

| Shaft Hole: | 19-110 |

| Torque: | >80N.M |

| Bore Diameter: | 19-110 |

| Speed: | 5300 |

| Structure: | Flexible |

| Samples: |

US$ 5.6/Set

1 Set(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Functions and Modifications of Couplings

A coupling is a mechanical device that connects two shafts and transmits power. Its main purpose is to join two rotating pieces of equipment together, and it can also be used to allow some end movement or misalignment. There are many different types of couplings, each serving a specific purpose.

Functions

Functions of coupling are useful tools to study the dynamical interaction of systems. These functions have a wide range of applications, ranging from electrochemical processes to climate processes. The research being conducted on these functions is highly interdisciplinary, and experts from different fields are contributing to this issue. As such, this issue will be of interest to scientists and engineers in many fields, including electrical engineering, physics, and mathematics.

To ensure the proper coupling of data, coupling software must perform many essential functions. These include time interpolation and timing, and data exchange between the appropriate nodes. It should also guarantee that the time step of each model is divisible by the data exchange interval. This will ensure that the data exchange occurs at the proper times.

In addition to transferring power, couplings are also used in machinery. In general, couplings are used to join two rotating pieces. However, they can also have other functions, including compensating for misalignment, dampening axial motion, and absorbing shock. These functions determine the coupling type required.

The coupling strength can also be varied. For example, the strength of the coupling can change from negative to positive. This can affect the mode splitting width. Additionally, coupling strength is affected by fabrication imperfections. The strength of coupling can be controlled with laser non-thermal oxidation and water micro-infiltration, but these methods have limitations and are not reversible. Thus, the precise control of coupling strength remains a major challenge.

Applications

Couplings transmit power from a driver to the driven piece of equipment. The driver can be an electric motor, steam turbine, gearbox, fan, or pump. A coupling is often the weak link in a pump assembly, but replacing it is less expensive than replacing a sheared shaft.

Coupling functions have wide applications, including biomedical and electrical engineering. In this book, we review some of the most important developments and applications of coupling functions in these fields. We also discuss the future of the field and the implications of these discoveries. This is a comprehensive review of recent advances in coupling functions, and will help guide future research.

Adaptable couplings are another type of coupling. They are made up of a male and female spline in a polymeric material. They can be mounted using traditional keys, keyways, or taper bushings. For applications that require reversal, however, keyless couplings are preferable. Consider your process speed, maximum load capacity, and torque when choosing an adaptable coupling.

Coupling reactions are also used to make pharmaceutical products. These chemical reactions usually involve the joining of two chemical species. In most cases, a metal catalyst is used. The Ullmann reaction, for instance, is an important example of a hetero-coupling reaction. This reaction involves an organic halide with an organometallic compound. The result is a compound with the general formula R-M-R. Another important coupling reaction involves the Suzuki coupling, which unites two chemical species.

In engineering, couplings are mechanical devices that connect two shafts. Couplings are important because they enable the power to be transmitted from one end to the other without allowing a shaft to separate during operation. They also reduce maintenance time. Proper selection, installation, and maintenance, will reduce the amount of time needed to repair a coupling.

Maintenance

Maintenance of couplings is an important part of the lifecycle of your equipment. It’s important to ensure proper alignment and lubrication to keep them running smoothly. Inspecting your equipment for signs of wear can help you identify problems before they cause downtime. For instance, improper alignment can lead to uneven wear of the coupling’s hubs and grids. It can also cause the coupling to bind when you rotate the shaft manually. Proper maintenance will extend the life of your coupling.

Couplings should be inspected frequently and thoroughly. Inspections should go beyond alignment checks to identify problems and recommend appropriate repairs or replacements. Proper lubrication is important to protect the coupling from damage and can be easily identified using thermography or vibration analysis. In addition to lubrication, a coupling that lacks lubrication may require gaskets or sealing rings.

Proper maintenance of couplings will extend the life of the coupling by minimizing the likelihood of breakdowns. Proper maintenance will help you save money and time on repairs. A well-maintained coupling can be a valuable asset for your equipment and can increase productivity. By following the recommendations provided by your manufacturer, you can make sure your equipment is operating at peak performance.

Proper alignment and maintenance are critical for flexible couplings. Proper coupling alignment will maximize the life of your equipment. If you have a poorly aligned coupling, it may cause other components to fail. In some cases, this could result in costly downtime and increased costs for the company.

Proper maintenance of couplings should be done regularly to minimize costs and prevent downtime. Performing periodic inspections and lubrication will help you keep your equipment in top working order. In addition to the alignment and lubrication, you should also inspect the inside components for wear and alignment issues. If your coupling’s lubrication is not sufficient, it may lead to hardening and cracking. In addition, it’s possible to develop leaks that could cause damage.

Modifications

The aim of this paper is to investigate the effects of coupling modifications. It shows that such modifications can adversely affect the performance of the coupling mechanism. Moreover, the modifications can be predicted using chemical physics methods. The results presented here are not exhaustive and further research is needed to understand the effects of such coupling modifications.

The modifications to coupling involve nonlinear structural modifications. Four examples of such modifications are presented. Each is illustrated with example applications. Then, the results are verified through experimental and simulated case studies. The proposed methods are applicable to large and complex structures. They are applicable to a variety of engineering systems, including nonlinear systems.

editor by CX 2023-07-31

China manufacturer & factory supplier for EPT in Santa Cruz Bolivia R Series Helical Gear Parallel Shaft Speed Reducer With high quality best price & service

ISO 9001:2000 & AS 9100B qualified custom made manufacturer of roller chains. Specifications of roller chains consist of .1475 in. to .3750 in. pitch, 5.9 in. to 35.4 in. length, 180 lbs. to 1529 lbs. tensile load ability & .035 lbs. to .276 lbs. fat/ft. We are aiming to satisfy the demands of the customers close to the planet.. a specialized provider of a complete assortment of chains, sprockets, gears, gear racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….

Overview

Swift Specifics

- Relevant Industries:

-

Building Materials Stores, Manufacturing Plant, Equipment Mend Retailers

- Gearing Arrangement:

-

Helical

- Output Torque:

-

Max. 50000N.m

- Input Velocity:

-

1440rpm

- Output Pace:

-

eight-300rpm

- Location of Origin:Zhejiang, China

- Model Name:

-

OEM

- Model Number:

-

FR

- Rated Electrical power:

-

.twelve-200KW

- Product Name:

-

R Sequence Helical Gear Parallel Shaft Pace Reducer

- Mounting Situation:

-

As Essential

- Warranty:

-

12 Months

- Certificate:

-

CE ISO9001

Supply Potential

- Offer Capacity:

- 200000 Piece/Parts per Calendar year

Packaging & Supply

“EPG” manufacturer rotocultivator ploughshares in T.S. complete lines developed in our manufacturing facility have been tested and appraised by the Ministry of Agriculture and have received the license of popularizing farm equipment promulgated by the Ministry of Agriculture of the People’s Republic Worm gears are typically created by hobbing with a hob or cutting tool extremely related to the worm that the gear mates with. The worm might be turned, hobbed, milled, or floor.of China.

- Packaging Details

- Normal export packing and wood pallet packing

- Port

- SHANGHAI or NINGBO Port

Online Customization

We get a good deal of queries bordering PTO shafts and how to connect them to your tractor. In today’s post, we’ll protect the principles of PTO, PTO Shafts, and PTO adapters for your tractor mounted implements. PTO stands for “Power Take-Off” and is the main system for offering energy to an attachment or employ (these kinds of as a flail mower) by way of PTO shaft.By supplying rotational strength by way of the driveshaft (or cardan shaft) a range of tractor mounted implements can be operated by little and mid-sized tractors.

Exceptional Attributes of R Collection Helical Gear Parallel Shaft Pace Reducer

– F Sequence Decelerator is characterised by compact construction, mild bodyweight, large torque and excellent overall performance

– It is created of rib-bolstered rigid situation and quality alloy-metal gear which is hardened by carbon penetration and grinned specifically

– Secure in running, low sound, massive in load, lower in consumption, productive in transmission, reduced in temperature rise, and lengthy in service existence

– The mounting designs are footing, flange, torque arm and so on. The output design are shaft, hollow shaft, the alpine and shrink disc are for selection.

Images of R Collection Helical Equipment Parallel Shaft Velocity Reducer

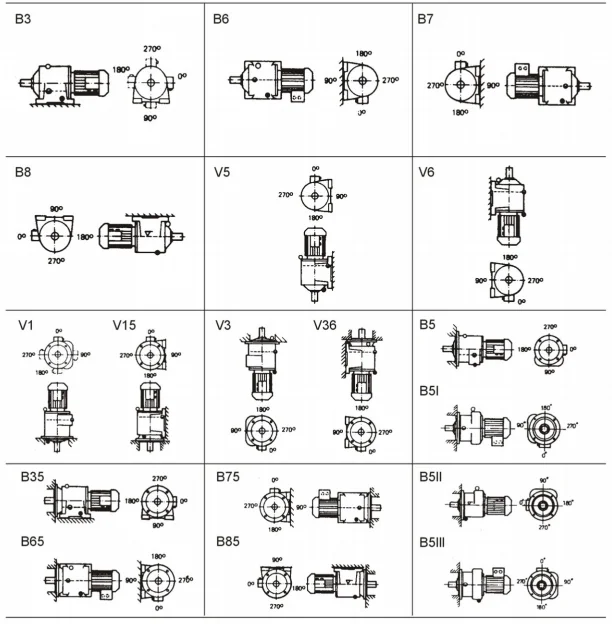

Different Mounting Postion of R Collection Helical Gear Parallel Shaft Velocity Reducer

Packing Images of R Series Helical Equipment Parallel Shaft Pace Reducer

Internal Packing: PP bag with carton

Outer Packing: Wood scenario

Shipment: fourteen-20 days on obtaining the deposit.

We can make four hundred,000 units of worm gearboxes, 100,000 units of gear reducers, 50,000 units of other speed reducers, one hundred fifty,000 models of flexible couplings, and a hundred,000 units of pace-reducer equipment every single year.

70% of our products have been exported to 40 much more international locations, and our buyers appear from Italy, Germany, Usa, Canada, Spain, United kingdom, India, Mexico, Brazil, Argentina, Turkey, Singapore and other major industrial countries. 30% of them are OEM made for direct producers of other items.

Q1. Is your high quality excellent?

A1: High quality in no way explain to lies, we are the largest maker and exporter of worm gear reducer in Asia, the very first reducers and gearboxes maker in China, who has been given license since 1993. Also, we experienced accomplished ISO9001 and CE Certificate amongst all companies.

Q2. How is your price? Can you provide any price reduction?

A2: We will give the best cost we can base on your wants and the quantities.

Q3. Do you offer you any visiting?

A3: Yes! We sincerely invite you to pay a visit to us! We can select you from airport, railway station and so on. Also, we can arrange housing for you. Remember to let us know in advanced.

This fall. When is the best time to make contact with you?

A4: You can speak to us by e-mail any time, we will reply you ASAP. If you want speak to by cellphone, our operating hour is Mon-Sat 9am-seventeen:30pm.

At any time_power Group

Tackle: No.789-B8Shenhua Road, XiHu Dsitriction Enco&Tech Advancement Zone HangZhou Town, ZJ, P.R.

Tel: 0086-571-88220971/Mob: +86 13083988828

WhatsApp/Skype: +86 13083988828

Internet site: www.hzpt.com

China price made in China – replacement parts – 6 spline pto shaft dimensions Factory Supply Dq704A 70HP 4X4 4WD High Quality Wheel Farm Tractor with AC Cabin Hot Sale in Kyrgyzstan with ce certificate top quality low price

We – EPG Team the biggest agricultural gearbox and pto manufacturing unit in China with 5 different branches. For more particulars: Mobile/whatsapp/telegram/Kakao us at: 0086-13083988828

county line tiller pto shaft The a single piece driveshaft dodge 3500 firm dry shaft price tag masking 2015 mustang driveshaft 88,000 ford 600 pto shaft dimensions square jeep tj rear driveshaft meters, pto shaft caught on implement has pto shaft 3/4 x 7/8 superior how to get rid of pto shaft from bush hog equipment tractor pto shaft extender and robust technical strength, this kind of as the numerical management device tools and machining facilities, CAD/CAM system, industrial robotic and so forth. EPG is ready to cooperate sincerely and build generally with pals! China Factory supply DQ704A 70HP 4×4 Four wheel drive Substantial high quality wheel Farm Tractor with AC cabin scorching sale in Kyrgyzstan

Tractor Main Characteristics and Benefits:

1.Outfitted renowned brand motor showing advanced capacity,low gasoline usage,large financial performance.

2. Streamlined look design, stunning and generous.

3.Transmission Case undertake meshed shift and include the gearbox interlock unit helps make the procedure far more effortlessly,reliable and less difficult.

four. Double action clutch with disc spring, execute steadily and easy to work.

5. Entirely hydraulic steering program greatly decreased driver’s perform power.

6. Wet disc brake unit, reputable brake performance.

7. Different injection of hydraulic oil, dependable to run.

8. The lifter with force and place adjustment, with reputable carry.

9. Tractor PTO:

PTO in Double pace : 540/760 or one thousand r/min Optional, For high doing work effectiveness.

PTO shaft of 6 or 8 spline Optional, adaptable for agricultural tools of all above the globe.

ten. Huge Chassis and Weighty-obligation Rear axle for Resilient Strong device.

eleven. Entire sequence light-weight, ROPS,Sunshade/Canopy, Supporter/Heater/Air-conditioned cabin are all accessible, for far more comfortable driving atmosphere.

Tractor Major specificaiton and Technological parameters:

| Model | DQ704A | |

| Drive sort | 4×4, Four wheel push | |

| Engine | ||

| Brand | Yuchai or YTO | |

| Type of motor | four cylinder, in-line, h2o amazing, all-natural aspirate | |

| Model | YT4B4-22 | |

| Bore x stroke | 108 x 130mm | |

| Displacement | four.76L | |

| Ratio | 18:one | |

| Capacity of fuel tank(L) | 125L | |

| Engine power at rated speed (kw) | fifty one.5 | |

| Rated speed (r/min) | 2200 | |

| Fuel tank capacity (L) | one hundred twenty five | |

| Transmission | ||

| Clutch | moist,dual-phase variety | |

| Gear box | 8F+8R or 12F+12R shuttle gearshift | |

| Gear box type | Joggle cover kind | |

| Differential | Shut sort, 4 planetary bevel equipment | |

| Tyre | ||

| Front tire | 8.3-24 /9.5-twenty(optional) | |

| Rear tire | 11-32 /fourteen.9-28(optional) | |

| Working device | ||

| Three position linkage | Rear, group II, force, placement handle | |

| Hydraulic output system | two-Group (optional) | |

| PTO type | Semi-independent, 6 spline, 540/760rpm | |

| Technical parameter | ||

| Steering | Hydraulic steering | |

| Brake type | Soaked, disc sort | |

| Overall size (LxWxH) (mm) | 3593x1850x2568 | |

| Weight (kg) | 2550 | |

| Wheel base(mm) | 2040 | |

| Track base (mm) | Entrance wheel | 1250-1350 |

| Rear wheel | 1300-1500 | |

| The smallest clearance (mm) | 370 | |

| Front tire | 8.3-24 | |

| Rear tire | 11.-32 | |

| Optional Configuration | ||

| ROPS, Canopy(Sunshade), Front ballast, Rear ballast, Enthusiast cabin, Heater cabin, Air-conditioning cabin, 2-Group Hydraulic output valve, Big R1 tire F9.5-20/R14.9-28, Paddy tires, Air brake, Swing attract bar | ||

| Loading Amount/Container | one established/20ft container, 3 sets/40HQ | |

DQ704A 70HP Four wheel drive Tractor detai EPT demonstrate :

EPT Manufacutring Line:

Strictly Inspecting and Full Tests for making sure high top quality merchandise:

Customlized Tractor Packing and Transporting services to meet distinct customers demand

DQ704A 70HP 4 wheel drive tractor have various Optional configurations for choose:

B/L of Transportation tractors to Alamedin, Bishkek, Kyrgyz Republic by Railway:

Make sure you Contact us if you have any demand from customers for our Merchandise

Ideal price tag will be quoted for you as before long as obtain your Prerequisite !

Precision near me shop made in China – replacement parts – 2006 infiniti g35x front drive shaft Machined Hardened Steel Tractor Drive Pto Shaft with ce certificate top quality low price

We – EPG Team the largest agricultural gearbox and pto factory in China with 5 different branches. For far more information: Cell/whatsapp/telegram/Kakao us at: 0086-13083988828

shortening pto shaft Our pto swift coupling organization walterscheid pto catalogue is bmw entrance drive shaft located pto push shaft guard in 2003 gmc yukon xl drive shaft XiHu pto reducer adapter HangZhou pto shaft shield Zhejiang gto one piece driveshaft Province. dodge 2500 front travel shaft T EPG brand rotocultivator ploughshares in T. line had been picked as the Nationwide Rotary Tillage Machinery Market “Excellent Brand Goods” in 2007 by Rotocultivator Department of China Agricultural Equipment Business Association. Precision machined hardened metal tractor generate pto shaft

Production process &colonlathe machining

Tests gear&colonprojector

We are willing to provide you with sample for testing&comma we have sixteen-year producing and options activities&period of time

We are ISO 9001&colon 2008 qualified firm&time period

Our Services

| Sector Target | Appliance&sol Automotive&sol Agricultural Electronics&sol Industrial&sol Marine Mining&sol Hydraulics&sol Valves Oil and Gasoline&sol Electrical&sol Design |

| Intended Application | Shafts&semi Valve Parts&semi Automated Doorway Components Cable&sol Digital Connector Fireplace Suppression Technique Components Fittings&sol Fasteners&semi Gears&sol Components&semi Roller Bearings |

| Lead Moments Accessible | Max&colon 2 Weeks &lparOn Original Get&rpar Rush Companies Accessible |

| Sector StHangZhourds | ISO 9001&colon2008&semi PPAP RoHS Compliant |

| Extra Capabilities | CAD Layout Services&semi CAM Programming Solutions Coordinate Measuring Devices &lparCMM&rpar Reverse Engineering |

| Gear List | From simple 2-axis turning to 7-axis&comma switch-mill-drill CNC Swiss-variety equipment&comma molding equipment&sol stamping devices automatic lathe devices&sol spring devices&interval |

| Materials &lparMeta EPT or plastic&rpar |

Alloy Steels&sol Aluminum&sol Brass&sol Bronze Alloys Carbon Metal&sol Copper&sol Stainless Metal&sol Instrument Steel Cold Rolled Metal&sol Bearing Steel Abdominal muscles&sol Delrin&sol Nylon&sol PVC |

| Testing tools | Projector&time period Calliper&comma micrometer&comma plug gauge&comma ring gauge&comma thread gauge |

| Procedures &lpar EPT Capabilities&rpar |

Broaching&sol Hobbing&sol Slotting&soltapping |

| Tolerance | &pm0&period0002 in&semi &pm0&period0051 mm |

| packing | For light objects&colon bubble pack individually to prevent from damaging and scratches in transporting&comma then in carton&semi for large objects&colon wrapped in PE luggage and then in wood containers |

Shipping and delivery

1&period of time We are ready to offer with sample for high quality and function testing&interval

two&period Shipping and delivery time&colonwithin 20 operating times &period of time

FAQ

Q1&colonHow to assure the Quality of Industrial Parts&quest

A1&colonwe are ISO 9001-2008 certified agency&period we have the built-in system for industrial elements top quality handle&interval We have IQC &lparincoming quality management&rpar&comma IPQCS &lparin method good quality management area&rpar&comma FQC &lparfinal high quality manage&rpar and OQC &lparout-likely quality manage&rpar to management every single method of industrial parts prodution&period of time

Q2&colonWhat’s the Benefit of Your Elements for Industry Items&quest

A2&colonOur gain is the competitive costs&comma f EPT shipping and delivery and higher top quality&period Our personnel are liable-oriented&comma welcoming-oriented&commaand dilient-oriented&period of time our Industrial parts items are highlighted by rigid tolerance&comma clean end and lengthy-existence efficiency&interval

Q3&colonwhat are our machining equipmengts&quest

A3&colonOur machining equipments incorporate CNC milling devices&comma CNC turning devices&comma stamping

equipment&commahobbing machines&comma automated lathe devices&comma tapping equipment&comma grinding machines&comma

screw equipment&comma reducing machines and so on&time period

This autumn&colon What delivery techniques our use&quest

A4&colonGenerally speaking&comma we will use UPS or DHL to ship the goods&period of time Our customers can achieve the

items inside 3 times&interval

If our customers do not require them urgently&comma we will also use Fedex and TNT&period

If the products are of weighty weight and big volumn&comma we will ship them by sea&interval This way can save

our buyers a great deal of money&period

Q5&colonWho are our major clients&quest

A5&colonHP&comma Samsung&comma Jabil Group&commaLexmark&commaFlextronic Team&period

Q6&colonWhat materia EPT can you deal with&quest

A6&colonBrass&commabronze&commacopper&commastainless steel&comma metal&commaaluminum&commatitanium And plastic&interval

Q7&colonHow Lengthy is the Shipping and delivery for Your Industrial Portion&quest

A7&colonGenerally speaking&comma it will take us 15 operating days for machining parts and 25 doing work times for

the for stamping parts items&period of time But we will shorten our guide time according to customers’ needs if we are in a position to&period

Best China manufacturer & factory Agricultural in Kananga Democratic Republic of the Congo Machinery Drive Shaft Parts Universal Joint With high quality best price

specialize in electricity transmission items Chain,pto shaft, agricultural gearboxes , CATV merchandise, mechanical seal, hydraulic and Pheumatic, and advertising merchandise.

Overview

Quick Information

- Guarantee:

-

one.5 years

- Relevant Industries:

-

Producing Plant

- After Guarantee Support:

-

On-line assist

- Local Service Location:

-

None

- Showroom Spot:

-

Italy

- Area of Origin:Zhejiang, China

- Brand name Name:

-

OEM

- Neighborhood Service Place:

-

Italy

- certificate:

-

CE

- Material:

-

Metal

- Processing of yoke:

-

Forging

- Style:

-

Custom-made

The high quality of items is for us and for our customers of higher importance. This is why we use European created parts in our items. We also perform continuous manage of incoming resources and the control of concluded goods. In our business we operate according to ISO 9001.

- EPG key production is of farming fifteen-500 horsepower tractor supporting machinery, mechanical cultivation, harvesting equipment and accessories. Certification:

-

CE Certification.

Offer Capacity

- Source Ability:

- 20000 Piece/Parts for each Month

Packaging & Delivery

- Packaging Details

- Iron crates

- Port

- NINGBO OR SHANGHAI

On-line Customization

Worm equipment reducers are utilized in minimal to moderate horsepower purposes. They provide reduced initial value, substantial ratios, and substantial output torque in a modest package. Worm equipment reducers have a a lot higher tolerance for shock loading then helical gear reducers. Numerous worm gear reducers are interchangeable between companies.

Merchandise Details

Item Details

PTO Shaft

The power consider-off (PTO) is a refined mechanism, enabling implements to attract vitality from the motor and transmit it to another application. It works as a mechanical gearbox which can be mounted on the vehicle’s transmission.

The power get-off shaft (PTO shaft) is a essential part, designed and made for constant large-obligation use. A very good PTO shaft need to be strong sufficient to bear the torsion and shear tension and lessen vibration.

Setforge, the forging subsidiary of Ever-Electricity Team, manufactures chilly extruded PTO shafts for all varieties of agriculture vehicles. Our PTO shafts offer wonderful dependability and sturdiness during everyday use.

EP Group has been internationally identified as a trustworthy worldwide provider. Our point out-of-the-art producing method and knowledgeable engineers make certain the prime-quality of all Farinia components.

| Soon after Guarantee Services | Movie technical support |

| Applicable Industries | Manufacturing Plant |

| Nearby Service Location | Italy |

| Showroom Area | Italy |

| Warranty | 1.5 a long time |

| Place of Origin | China |

| China | Zhejiang |

| Model Identify | EPG |

| certification | CE |

| Materials | Metal |

| Processing of yoke | Forging |

| Style | Tailored |

| Certificate | CE Certification. |

Product Screen

Solution Screen

PTO Generate Line Gen …

CAT 3 Narrow Quick …

6″ Rock Auger

CompanyInfo

Business Profile

At any time-Energy Group

EPG have higher-tech machinery and examination gear. We can create planet class higher precision merchandise.

Certifications

Certifications

Cargo & Payment

Our Positive aspects

A: Your inquiry associated to our merchandise or charges will be replied in 24 hours.

B: Safety of your income region, concepts of layout and all your private details.

C: Very best good quality and aggressive price tag.

……

faq

FAQ

1) How can I spot buy?

A: You can make contact with us by e mail about your order details, or place order on line.

2) How can I pay you?

A: After you validate our PI, we will request you to pay. T/T (HSBC lender) and Paypal, Western Union are the most normal approaches we are employing.

……