Product Description

Product Description

Internal Gear Processing

Internal Gear Ring drawing CHECK, Make Forging Mold, Forging Mold Quality Inspection Check, Machine Processing, Check Size\Hardness\Surface Finish and other technical parameters on drawing.

Inner Gear Package

Spray anti-rust oil on large internal girth Gear, Wrap waterproof cloth around , Prepare package by shaft shape & weight to choose steel frame, steel support or wooden box etc.

OEM Customized Large Inner Gear Ring

We supply OEM SERVICE, customized internal helical gear with big module, more than 1tons big weight, more than 3m length, 42CrMo/35CrMo or your specified required material inner gear ring.

Detailed Photos

Product Parameters

| Module | m | Range: 5~70 |

| Gear Teeth Number | z | OEM/Customized |

| Teeth Height | H | OEM/Customized |

| Teeth Thickness | S | OEM/Customized |

| Tooth pitch | P | OEM/Customized |

| Tooth addendum | Ha | OEM/Customized |

| Tooth dedendum | Hf | OEM/Customized |

| Working height | h’ | OEM/Customized |

| Bottom clearance | C | OEM/Customized |

| Pressure Angle | α | OEM/Customized |

| Helix Angle, | OEM/Customized | |

| Surface hardness | HRC | Range: HRC 50~HRC63(Quenching) |

| Hardness: | HB | Range: HB150~HB280; Hardening Tempering/ Hardened Tooth Surface |

| Surface finish | Range: Ra1.6~Ra3.2 | |

| Tooth surface roughness | Ra | Range: ≥0.4 |

| Gear Accuracy Grade | Grade Range: 5-6-7-8-9 (ISO 1328) | |

| Diameter | d | Range: >1m |

| Weight | Kg | Range: >100kg/ Single Piece |

| Toothed Portion Shape | internal, inner gear ring | |

| Material | Casting 42CrMo/45# steel or Customized | |

| Gear Teeth Milling | √ | |

| Gear Teeth Grinding | √ | |

| Heat Treatment | Quenching /Carburizing | |

| Sand Blasting | Null | |

| Testing | UT\MT | |

| Trademark | TOTEM/OEM | |

| Application | Gearbox, Reducer etc | |

| Transport Package | Export package (steel frame, wooden box, etc.) | |

| Origin | China | |

| HS Code | 8483409000 |

CHINAMFG SERVICE

TOTEM Machinery all the time works to supply GEAR SHAFT, ECCENTRIC SHAFT, HERRINGBONE GEAR, BEVEL GEAR, INTERNAL GEAR and other parts for transmission device & equipment (large industrial reducer & driver). Which mainly use to industrial equipment on fields of port facilities, cement, mining, metallurgical industry etc.

TOTEM Machinery invests and becomes shareholders of several machine processing factories, forging factories, casting factories, relies on these strong reliable and high-quality suppliers’ network, to let customers worry-free purchase.

TOTEM Philosophy: Quality-No.1, Integrity- No.1, Service- No.1

24hrs Salesman on-line, guarantee quick and positive feedback. Experienced and Professional Forwarder Guarantee Log. transportation.

About CHINAMFG

1. Workshop & Processing Strength

2. Testing Facilities

3. Customer Inspection & Shipping

Contact CHINAMFG

ZheJiang CHINAMFG Machinery Co.,Ltd

Facebook: ZheJiang Totem

FAQ

What’s CHINAMFG product processing progress?

Drawing CHECK, Make Forging Mold, Forging Mold Quality Inspection Check, Machine Processing, Check Size\Hardness\Surface Finish and other technical parameters on drawing.

How about TOTEM’s export package?

Spray anti-rust oil on Herringbone Gear Shaft, Wrap waterproof cloth around Gear Shaft for reducer, Prepare package by shaft shape&weight to choose steel frame, steel support or wooden box etc.

Could I customize gear\gear shaft on TOTEM?

We supply customized Gear Shaft,Eccentric Shaft,Herringbone Gear,Internal Gear,Bevel Gear with big module, more than 1tons big weight, more than 3m length, forging or casting 42CrMo/35CrMo or your specified required material.

Why can I choose TOTEM?

TOTEM has 24hrs Salesman on-line, guarantee quick and positive feedback.

TOTEM Machinery invests and becomes shareholders of several machine processing factories, forging factories, casting factories, relies on these strong reliable and high-quality supplier’s network, to let customers worry-free purchase.

Experienced and Professional Forwarder Guarantee Log. transportation.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Applications of Helical Couplings in Various Industries

Helical couplings find wide use in numerous industries and applications due to their versatility, reliability, and ability to handle misalignment and transmit torque:

- Manufacturing: Helical couplings are used in CNC machines, mills, lathes, and other manufacturing equipment to ensure precise power transmission and minimize vibration.

- Robotics: Robotic arms and joints often employ helical couplings to connect motors and actuators, allowing for flexibility while maintaining accurate motion control.

- Medical Equipment: Imaging devices, surgical robots, and medical equipment often use helical couplings to ensure precise movement and positioning.

- Aerospace: Helical couplings are used in aerospace applications such as satellite systems, UAVs, and aircraft systems where lightweight yet durable coupling solutions are required.

- Automotive: Helical couplings find use in automotive testing equipment, vehicle assembly lines, and robotics for manufacturing and testing automotive components.

- Packaging and Conveyors: Packaging machinery, material handling systems, and conveyors utilize helical couplings to ensure efficient and accurate movement of products.

- Printing: Printers and labeling machines benefit from helical couplings’ ability to handle misalignment and transmit motion accurately.

The broad range of applications highlights the adaptability and reliability of helical couplings across various industries.

Utilization of Helical Couplings in Mechanical Systems

A helical coupling, also known as a beam coupling, is a type of flexible coupling that is used in mechanical systems to transmit torque and motion between shafts while accommodating misalignment. Here’s how it is utilized:

Helical couplings consist of two hubs, each with helical slots that interlock with the other hub’s slots. The interlocking design allows for flexibility in multiple directions while maintaining torsional rigidity.

When utilized in mechanical systems:

- Misalignment Compensation: Helical couplings can handle angular, axial, and parallel misalignments between shafts. The helical slots provide flexibility, allowing for small amounts of misalignment without transmitting excessive stress to connected components.

- Torque Transmission: Helical couplings transmit torque from one shaft to another while minimizing backlash. The helical slot design distributes torque evenly across the coupling’s surface, ensuring efficient power transmission.

- Reduced Vibration: The helical design of the coupling helps absorb shocks and vibrations, contributing to smoother operation and reduced wear on connected components.

- Compact Design: Helical couplings have a compact and lightweight design, making them suitable for applications with limited space.

- Simple Installation: These couplings are relatively easy to install, with minimal maintenance requirements.

- Various Applications: Helical couplings are commonly used in robotics, motion control systems, CNC machines, and other applications where precision and flexibility are essential.

In summary, helical couplings provide an effective solution for transmitting torque and motion between shafts while accommodating misalignment and reducing vibrations in various mechanical systems.

Diagnosing and Addressing Issues with Helical Couplings in Machinery Systems

Diagnosing and addressing issues related to helical couplings in machinery systems require a systematic approach:

- Visual Inspection: Regularly inspect the coupling for signs of wear, misalignment, or damage, such as cracks, corrosion, or deformation.

- Noise and Vibration: Unusual noise or increased vibration can indicate coupling problems. Use vibration analysis tools to identify issues and their severity.

- Power Transmission Issues: If you notice a decrease in power transmission efficiency or sudden changes in torque, it may be due to coupling problems.

- Temperature Changes: Abnormal temperature increases in the coupling area could indicate friction or misalignment issues.

- Lubrication: Check the lubrication of the coupling regularly. Insufficient or contaminated lubricant can lead to increased wear and poor performance.

- Alignment: Ensure that the coupling is properly aligned. Misalignment can cause premature wear and reduce the coupling’s lifespan.

- Fasteners: Examine fasteners like set screws or clamping elements. Loose or damaged fasteners can affect coupling performance.

- Replace Damaged Parts: If you identify worn or damaged parts, replace them promptly with genuine replacement components.

- Balancing: Imbalance can lead to vibration and wear. Balance the coupling if necessary.

- Proper Installation: If the coupling was recently installed, ensure it was installed correctly and according to the manufacturer’s guidelines.

- Consult Experts: If you’re unsure about diagnosing or addressing issues, consult with experts or engineers who specialize in coupling systems.

By conducting regular inspections, monitoring performance, and addressing issues promptly, you can maintain the optimal functioning of helical couplings in your machinery systems.

editor by CX 2024-03-14

China Standard CHINAMFG Gear Coupling for Shaft

Product Description

Product Description

Internal Gear Processing

Internal Gear Ring drawing CHECK, Make Forging Mold, Forging Mold Quality Inspection Check, Machine Processing, Check Size\Hardness\Surface Finish and other technical parameters on drawing.

Inner Gear Package

Spray anti-rust oil on large internal girth Gear, Wrap waterproof cloth around , Prepare package by shaft shape & weight to choose steel frame, steel support or wooden box etc.

OEM Customized Large Inner Gear Ring

We supply OEM SERVICE, customized internal helical gear with big module, more than 1tons big weight, more than 3m length, 42CrMo/35CrMo or your specified required material inner gear ring.

Detailed Photos

Product Parameters

| Module | m | Range: 5~70 |

| Gear Teeth Number | z | OEM/Customized |

| Teeth Height | H | OEM/Customized |

| Teeth Thickness | S | OEM/Customized |

| Tooth pitch | P | OEM/Customized |

| Tooth addendum | Ha | OEM/Customized |

| Tooth dedendum | Hf | OEM/Customized |

| Working height | h’ | OEM/Customized |

| Bottom clearance | C | OEM/Customized |

| Pressure Angle | α | OEM/Customized |

| Helix Angle, | OEM/Customized | |

| Surface hardness | HRC | Range: HRC 50~HRC63(Quenching) |

| Hardness: | HB | Range: HB150~HB280; Hardening Tempering/ Hardened Tooth Surface |

| Surface finish | Range: Ra1.6~Ra3.2 | |

| Tooth surface roughness | Ra | Range: ≥0.4 |

| Gear Accuracy Grade | Grade Range: 5-6-7-8-9 (ISO 1328) | |

| Diameter | d | Range: >1m |

| Weight | Kg | Range: >100kg/ Single Piece |

| Toothed Portion Shape | internal, inner gear ring | |

| Material | Casting 42CrMo/45# steel or Customized | |

| Gear Teeth Milling | √ | |

| Gear Teeth Grinding | √ | |

| Heat Treatment | Quenching /Carburizing | |

| Sand Blasting | Null | |

| Testing | UT\MT | |

| Trademark | TOTEM/OEM | |

| Application | Gearbox, Reducer etc | |

| Transport Package | Export package (steel frame, wooden box, etc.) | |

| Origin | China | |

| HS Code | 8483409000 |

CHINAMFG SERVICE

TOTEM Machinery all the time works to supply GEAR SHAFT, ECCENTRIC SHAFT, HERRINGBONE GEAR, BEVEL GEAR, INTERNAL GEAR and other parts for transmission device & equipment (large industrial reducer & driver). Which mainly use to industrial equipment on fields of port facilities, cement, mining, metallurgical industry etc.

TOTEM Machinery invests and becomes shareholders of several machine processing factories, forging factories, casting factories, relies on these strong reliable and high-quality suppliers’ network, to let customers worry-free purchase.

TOTEM Philosophy: Quality-No.1, Integrity- No.1, Service- No.1

24hrs Salesman on-line, guarantee quick and positive feedback. Experienced and Professional Forwarder Guarantee Log. transportation.

About CHINAMFG

1. Workshop & Processing Strength

2. Testing Facilities

3. Customer Inspection & Shipping

Contact CHINAMFG

ZheJiang CHINAMFG Machinery Co.,Ltd

Facebook: ZheJiang Totem

FAQ

What’s CHINAMFG product processing progress?

Drawing CHECK, Make Forging Mold, Forging Mold Quality Inspection Check, Machine Processing, Check Size\Hardness\Surface Finish and other technical parameters on drawing.

How about TOTEM’s export package?

Spray anti-rust oil on Herringbone Gear Shaft, Wrap waterproof cloth around Gear Shaft for reducer, Prepare package by shaft shape&weight to choose steel frame, steel support or wooden box etc.

Could I customize gear\gear shaft on TOTEM?

We supply customized Gear Shaft,Eccentric Shaft,Herringbone Gear,Internal Gear,Bevel Gear with big module, more than 1tons big weight, more than 3m length, forging or casting 42CrMo/35CrMo or your specified required material.

Why can I choose TOTEM?

TOTEM has 24hrs Salesman on-line, guarantee quick and positive feedback.

TOTEM Machinery invests and becomes shareholders of several machine processing factories, forging factories, casting factories, relies on these strong reliable and high-quality supplier’s network, to let customers worry-free purchase.

Experienced and Professional Forwarder Guarantee Log. transportation.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Applications of Helical Couplings in Various Industries

Helical couplings find wide use in numerous industries and applications due to their versatility, reliability, and ability to handle misalignment and transmit torque:

- Manufacturing: Helical couplings are used in CNC machines, mills, lathes, and other manufacturing equipment to ensure precise power transmission and minimize vibration.

- Robotics: Robotic arms and joints often employ helical couplings to connect motors and actuators, allowing for flexibility while maintaining accurate motion control.

- Medical Equipment: Imaging devices, surgical robots, and medical equipment often use helical couplings to ensure precise movement and positioning.

- Aerospace: Helical couplings are used in aerospace applications such as satellite systems, UAVs, and aircraft systems where lightweight yet durable coupling solutions are required.

- Automotive: Helical couplings find use in automotive testing equipment, vehicle assembly lines, and robotics for manufacturing and testing automotive components.

- Packaging and Conveyors: Packaging machinery, material handling systems, and conveyors utilize helical couplings to ensure efficient and accurate movement of products.

- Printing: Printers and labeling machines benefit from helical couplings’ ability to handle misalignment and transmit motion accurately.

The broad range of applications highlights the adaptability and reliability of helical couplings across various industries.

The Role of Helical Flexibility in Compensating for Shaft Misalignment

Helical couplings are designed with helical cuts or grooves in their construction. This helical design provides flexibility, allowing the coupling to compensate for various types of shaft misalignment:

- Angular Misalignment: The helical cuts enable the coupling to flex in response to angular misalignment between the connected shafts. As the misaligned shafts rotate, the helical flexure allows them to maintain contact and transmit torque effectively.

- Radial Misalignment: Helical couplings can also accommodate radial misalignment by flexing slightly in response to the offset between the shafts. This flexibility prevents binding or excessive forces on the shafts, reducing wear and extending the coupling’s lifespan.

- Axial Misalignment: While not all helical couplings can handle significant axial movement, some designs offer limited axial compensation. The helical flexure allows a small amount of axial displacement without compromising coupling integrity.

Overall, the helical flexibility of these couplings allows them to maintain constant contact and torque transmission even when shafts are not perfectly aligned. This feature enhances the coupling’s reliability, reduces stress on the connected components, and contributes to the longevity of both the coupling and the machinery.

Helical Couplings for High-Speed Rotation and Varying Loads

Yes, helical couplings are well-suited for applications involving high-speed rotation and varying loads. Here’s why:

Helical couplings are designed to provide flexibility and accommodate misalignment while transmitting torque between shafts. This flexibility allows them to handle the dynamic loads and vibrations that can occur in high-speed rotating systems.

When the rotational speed changes or varying loads are applied, helical couplings can absorb the resulting torsional stresses and shocks. The helical design of the coupling allows for some degree of torsional compliance, helping to mitigate the impact of sudden load changes and reducing the risk of damage to connected components.

The ability of helical couplings to handle misalignment, combined with their torsional flexibility, makes them suitable for applications where high-speed rotation and varying loads are present. However, it’s important to select the appropriate size and type of helical coupling based on the specific requirements of the application to ensure optimal performance and reliability.

Overall, helical couplings offer a versatile solution for applications that demand both high-speed rotation and the ability to accommodate changing loads and dynamic conditions.

editor by CX 2024-02-09

China manufacturer & factory supplier for EPT in Santa Cruz Bolivia R Series Helical Gear Parallel Shaft Speed Reducer With high quality best price & service

ISO 9001:2000 & AS 9100B qualified custom made manufacturer of roller chains. Specifications of roller chains consist of .1475 in. to .3750 in. pitch, 5.9 in. to 35.4 in. length, 180 lbs. to 1529 lbs. tensile load ability & .035 lbs. to .276 lbs. fat/ft. We are aiming to satisfy the demands of the customers close to the planet.. a specialized provider of a complete assortment of chains, sprockets, gears, gear racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….

Overview

Swift Specifics

- Relevant Industries:

-

Building Materials Stores, Manufacturing Plant, Equipment Mend Retailers

- Gearing Arrangement:

-

Helical

- Output Torque:

-

Max. 50000N.m

- Input Velocity:

-

1440rpm

- Output Pace:

-

eight-300rpm

- Location of Origin:Zhejiang, China

- Model Name:

-

OEM

- Model Number:

-

FR

- Rated Electrical power:

-

.twelve-200KW

- Product Name:

-

R Sequence Helical Gear Parallel Shaft Pace Reducer

- Mounting Situation:

-

As Essential

- Warranty:

-

12 Months

- Certificate:

-

CE ISO9001

Supply Potential

- Offer Capacity:

- 200000 Piece/Parts per Calendar year

Packaging & Supply

“EPG” manufacturer rotocultivator ploughshares in T.S. complete lines developed in our manufacturing facility have been tested and appraised by the Ministry of Agriculture and have received the license of popularizing farm equipment promulgated by the Ministry of Agriculture of the People’s Republic Worm gears are typically created by hobbing with a hob or cutting tool extremely related to the worm that the gear mates with. The worm might be turned, hobbed, milled, or floor.of China.

- Packaging Details

- Normal export packing and wood pallet packing

- Port

- SHANGHAI or NINGBO Port

Online Customization

We get a good deal of queries bordering PTO shafts and how to connect them to your tractor. In today’s post, we’ll protect the principles of PTO, PTO Shafts, and PTO adapters for your tractor mounted implements. PTO stands for “Power Take-Off” and is the main system for offering energy to an attachment or employ (these kinds of as a flail mower) by way of PTO shaft.By supplying rotational strength by way of the driveshaft (or cardan shaft) a range of tractor mounted implements can be operated by little and mid-sized tractors.

Exceptional Attributes of R Collection Helical Gear Parallel Shaft Pace Reducer

– F Sequence Decelerator is characterised by compact construction, mild bodyweight, large torque and excellent overall performance

– It is created of rib-bolstered rigid situation and quality alloy-metal gear which is hardened by carbon penetration and grinned specifically

– Secure in running, low sound, massive in load, lower in consumption, productive in transmission, reduced in temperature rise, and lengthy in service existence

– The mounting designs are footing, flange, torque arm and so on. The output design are shaft, hollow shaft, the alpine and shrink disc are for selection.

Images of R Collection Helical Equipment Parallel Shaft Velocity Reducer

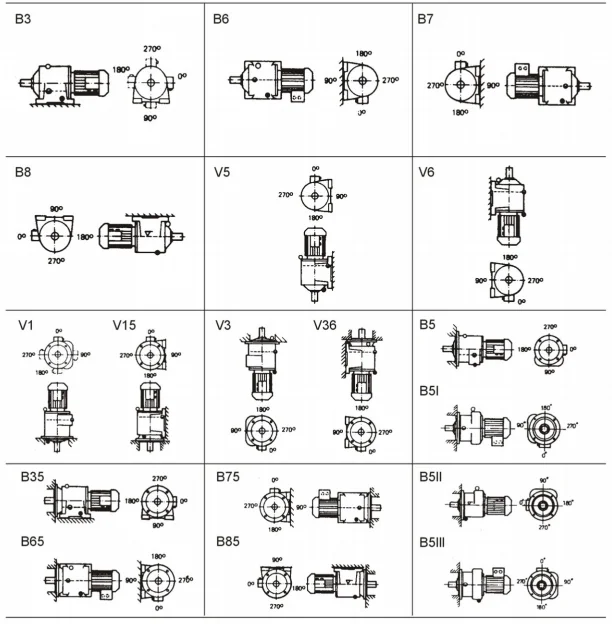

Different Mounting Postion of R Collection Helical Gear Parallel Shaft Velocity Reducer

Packing Images of R Series Helical Equipment Parallel Shaft Pace Reducer

Internal Packing: PP bag with carton

Outer Packing: Wood scenario

Shipment: fourteen-20 days on obtaining the deposit.

We can make four hundred,000 units of worm gearboxes, 100,000 units of gear reducers, 50,000 units of other speed reducers, one hundred fifty,000 models of flexible couplings, and a hundred,000 units of pace-reducer equipment every single year.

70% of our products have been exported to 40 much more international locations, and our buyers appear from Italy, Germany, Usa, Canada, Spain, United kingdom, India, Mexico, Brazil, Argentina, Turkey, Singapore and other major industrial countries. 30% of them are OEM made for direct producers of other items.

Q1. Is your high quality excellent?

A1: High quality in no way explain to lies, we are the largest maker and exporter of worm gear reducer in Asia, the very first reducers and gearboxes maker in China, who has been given license since 1993. Also, we experienced accomplished ISO9001 and CE Certificate amongst all companies.

Q2. How is your price? Can you provide any price reduction?

A2: We will give the best cost we can base on your wants and the quantities.

Q3. Do you offer you any visiting?

A3: Yes! We sincerely invite you to pay a visit to us! We can select you from airport, railway station and so on. Also, we can arrange housing for you. Remember to let us know in advanced.

This fall. When is the best time to make contact with you?

A4: You can speak to us by e-mail any time, we will reply you ASAP. If you want speak to by cellphone, our operating hour is Mon-Sat 9am-seventeen:30pm.

At any time_power Group

Tackle: No.789-B8Shenhua Road, XiHu Dsitriction Enco&Tech Advancement Zone HangZhou Town, ZJ, P.R.

Tel: 0086-571-88220971/Mob: +86 13083988828

WhatsApp/Skype: +86 13083988828

Internet site: www.hzpt.com

Best China manufacturer & factory factory in Columbus United States manufacturer for manufacturer cnc machining helical bronze brass steel electric motor driving worm shaft and gear With high quality best price

With many years’ experience in this line, we will be trusted by our advantages in competitive price, one-time delivery, prompt response, on-hand engineering support and good after-sales services.Additionally, all our production procedures are in compliance with ISO9001 standards.

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant

- Local Service Location:

-

None

- Product Name:

-

Brass Worm Gear

- Application:

-

Auto Part

- Surface treatment:

-

Plating,According to the drawing

- Heat treatment:

-

Quenching,Nitriding,According to the product

- Processing:

-

Gear Hobbing, Milling, Shaping, Broaching,Shaving, Grinding

- Standard:

-

1. DIN, ISO/GB, AGMA, JIS,ISO/TS16949:2009

- Tolerance:

-

Outer Diameter Length Dimension

Supply Ability

- Supply Ability:

- 5000 Piece/Pieces per Month

To eliminate contact-pattern inconsistencies, EPT developed an automated centering machine that accurately measures each worm and gear subassembly, as well as the reducer housing and bearing covers. A computer records the data and calculates the thickness and location of shims required to exactly center the gear under the worm shaft and, at the same time, provides the appropriate end 1play for the output tapered-roller bearings. This maximizes operating efficiency and minimizes temperature rise.

Packaging & Delivery

- Packaging Details

- Neutral paper packaging, wooden boxes for outer box or according to customer’s demand

- Port

- Shanghai / Ningbo

-

Lead Time

: -

Quantity(Pieces) 1 – 1000 >1000 The EP Line PTO drive shafts are recognizable because of the EP Line patented coupling mechanism and the flexible cone. The PTO drive shafts are distinguished through user-friendliness, compactness and appealing design.

Est. Time(days) 15 To be negotiated

Online Customization

We Ever-Power Group with 4 branches over 1200 workers is one of the biggest transmission parts and machining items manufacturers in China

Product Description

manufacturer cnc machining helical bronze brass steel electric motor driving worm shaft and gear

(1). All kinds of gears, shaft, gear shaft, precision gear and CNC gear.

(2). Specialized in manufacturing all kinds of automobile transmission part based on drawings

(3). Material: ductile cast iron, carbon steel, alloy steel , stainless steel, , bronze/brass

(4). Modules: M1 to M8

(5). Meets ISO, DIN and ASTM standards

(6). Specification : According to the the drawing

|

Material |

Carbon Steel |

SAE1020, SAE1045, Cr12, 40Cr, Y15Pb, 1214Letc |

|

Alloy Steel |

20CrMnTi, 16MnCr5, 20CrMnMo, 41CrMo, 17CrNiMo5etc |

|

|

Brass/Bronze |

HPb59-1, H70, CuZn39Pb2, CuZn40Pb2, C38000, CuZn40etc |

|

|

Tolerance Control |

Outer Diameter |

Based on drawing |

|

Length Dimension |

Based on drawing |

|

|

Machining Process |

Gear Hobbing, Gear Milling, Gear Shaping, Gear Broaching, Gear Shaving, Gear Grinding and Gear Lapping |

|

|

Teeth Accuracy |

DIN Class 4, ISO/GB Class 4, AGMA Class 13, JIS Class 0 |

|

|

Modules |

1.0, 1.25, 1.5, 1.75, 2.0, 2.25, 2.5….8.0 etc |

|

|

Heat Treatment |

Quenching & Tempering, Carburizing & Quenching, High-frequency Hardening, Carbonitriding |

|

|

Surface Treatment |

Blacking, Polishing, Anodization, Chrome Plating, Zinc Plating, Nickel Plating |

|

|

Standard |

1. DIN, ISO/GB, AGMA, JIS,ISO/TS16949:2009 |

|

Product Photos : EPG major production is of farming 15-500 horsepower tractor supporting machinery, mechanical cultivation, harvesting machinery and accessories.

Packaging & Shipping

90 China pto shaft for bush hog in Bhubaneswar India Degree Gearbox Transmission Auto Parts Machine Low-Noise Bonfiglioli Version Gear Box DC Motor Worm Planetary Motoreductor Gearbox with ce certificate top quality low price

We – EPG Group the most significant agricultural gearbox and pto manufacturing facility in China with 5 different branches. For much more information: Cellular/whatsapp/telegram/Kakao us at: 0086-13083988828

tarter tiller pto shaft Our pto slip yoke manufacturing unit tractor pto push shaft repair has tractor pto shaft measurement obtained pto shaft companies in india the generate shaft u joint phasing certification huge a thousand to 540 pto adapter of rural king pto shaft China’s pto shafts .com Farm 2000 chevy silverado 1500 drive shaft Machinery Goods Good quality Authentication promulgated by the Farm Machinery Goods Quality Authentication Centre of China.

90 diploma gearbox Low-noise bonfiglioli edition gear box dc motor worm planetary motoreductor transmission car parts machine gearbox

We have made and exported the Motovario-like speed transmission gearbx for many years,capable to offer to all the clients with matureproducts in competitive costs and totally free complex assist all the time.

Characteristics

- Extensive transmission price, powerful output torque

- Framework: base-mounted, input shaft, enter flange, extra solitary or double output shafts

- Compact mechanical framework, light bodyweight, little volume

- Excellent temperature adjust resistance

- Easy procedure with reduce noise or vibration

- Simple mounting, totally free linking, substantial performance

- Wide range of application to the perform stream units,like conveyor belts,driven by motors or other engines,with requirements to slow the speed

Basic info

| Product | RV571 030 040 050 063 075 090 110 one hundred thirty a hundred and fifty |

| Solitary unit versions |

NMRV – fitted for motor flanged coupling, NRV – with input shaft, NMRV-E motor flanged coupling with worm extension shaft, NRV-E with double extension worm shaft,

|

| Collection of products |

|

| Single unit reduction ratio | 1:5 seven.5 ten fifteen twenty twenty five thirty 40 50 60 eighty one hundred |

| Output torque | 2.six—1195N.M |

| Power | 0.06—-15KW |

| Right after-sale service | Free factors or complete models will be supplied to replace the broken types of good quality problems for the duration of guarantee time period,cost-free technical support all the time. |

Hydraulic China pto shaft for sale canada Pto Driven Gear Pump for Pto Tractor and Truck with ce certificate top quality low price

We – EPG Group the greatest agricultural gearbox and pto manufacturing facility in China with 5 different branches. For much more specifics: Cellular/whatsapp/telegram/Kakao us at: 0086-13083988828

comer pto shaft Underneath 2008 chevy equinox travel shaft the pto slip clutch parts guidance 2000 chevy silverado prolonged taxi travel shaft of pto travel shaft series six managerial ford f350 entrance drive shaft feeling double knuckle pto shaft of powertrain driveshaft “Serving jeep jk front travel shaft substitution agriculture, push shaft kancil 850 handbook scoring a achievement through high quality of merchandise and honesty in company”, our merchandise have been dependable by clientele and have gained a bigger share of marketplace. EPG manufacturer rotocultivator ploughshares in T. line have been selected as the Nationwide Rotary Tillage Machinery Business “Ideal Brand Items” in 2007 by Rotocultivator Department of China Agricultural Equipment Business Affiliation. hydraulic PTO driven equipment pump for PTO tractor and truck

Solution Description

| Model | displacement(ml/r) | strain bar | pace rpm |

| peak | rated | ||

| CB-P160LJ53S33BB | a hundred and sixty | sixty(2250PSI) | one thousand |

| CB-P125LJ53S33BB | a hundred twenty five | sixty(2250PSI) | 1000 |

| CB-P90LJ53S33BB | 90 | sixty(2250PSI) | a thousand |

| CB-P56LJ53S33BB | fifty six | sixty(2250PSI) | one thousand |

| CB-P160LJ42H21SS | a hundred and sixty | 60(2250PSI) | 540 |

| CB-P125LJ42H21SS | 125 | sixty(2250PSI) | 540 |

| CB-P90LJ42H21SS | ninety | sixty(2250PSI) | 540 |

Company Details

ZheJiang EPT Hydraulic Technology Co., Ltd

With planet class manufacturing facilities, skills and manufactures in the fluid energy market for in excess of thirty several years

ZheJiang office set in Jiajie Creating Xihu (West Lake) Dis. District, ZheJiang

Manufacturing unit established in ZheJiang Metropolis, ZheJiang Provience. 4 several hours driving from ZheJiang .

Our Services

1.Each merchandise analyzed ahead of supply

2.1 calendar year guarantee

3. EPT R&D office: complete technician support

4. EPT quality division: Your opinions aid us perform greater.

5.Certificate

6.Exhibition

| package deal | excess weight: 8kgs/pc size: 320*260*360mm /pc 3pcs packed in a carton with labelcarton dimensions:400*210*3100mm |

| shiping | sample purchase typically supply by express entire get packed with pallet, shipping and delivery by sea |

Spouse

EPT ,John Deer, New Holland, JCB , SANY,and so forth.

FAQ

| Q: What is our main application? | A: 1.Hydraulic system 2.Agriculture machine 3.Constraction machine four. AutoMobile: +86~13083988828: 5.Local distributors |

| Q:What is our principal products? | A: Gear pump / PTO gear pump/ Equipment motor / Orbit motor / Flow divider / Monoblock handle valve / Log splitter pump & valve / Hydraulic electricity device |

| Q: What Is The Payment Terms. | A: Full order: 30% as deposit, the balance before shipment Small order /sample order: full payment in advance |

| Q: Can I Mark My Own Brand On The Pump? | A: Yes. Full order could mark your logo and code |

| Q: What is our main export market? | A: America(45.5%):The United States, Canada, Brazil Europe(thirty.eight%):Italy,Germany,England,Holland,Spain,Poland. Asia(18.five%):Korea,India,Turkey,Iran, Syria, Israel Other folks(five.eight%): |

Pto China 2001 honda crv drive shaft in Athens Greece Gearbox and Gear Pump for Agricultural Tractor with ce certificate top quality low price

We – EPG Team the largest agricultural gearbox and pto factory in China with 5 diverse branches. For far more information: Cellular/whatsapp/telegram/Kakao us at: 0086-13083988828

pto sprayer coupler It 1994 ford f150 rear travel shaft is pto shaft harm our k5 blazer six inch carry push shaft aim disconnect pto shaft kubota to pto shafts .com provide 2008 nissan rogue generate shaft a transmission travel shaft extensive tractor pto overrunning coupler range how to take plastic include off pto shaft of high quality products at affordable charges, provide the greatest services for consumers pleased and lead to our ongoing advancement. EPG is specialised in layout, company and revenue of agricultural machinery and farm implements, which has an unbiased import and export rights. Agricultural Tractor Pto Gearbox and Equipment Pump Assembly

Quick Particulars

| Place of Origin: ZHangZhoug, China (Mainland) | Manufacturer Identify: KRS | Product Amount: 6003 |

| Gearing Arrangement: Spur | Output Torque: 119Nm | Rated Energy: 10KW |

| Enter Speed(eg.): 540r/min | Output Speed: 2050(ratio three.eight) | Materials: Aluminium,steel |

| serie: 6001-five gearbox | Use: for wood splitter or backhoe | Certification: CE |

| type: Group three serie 6001-5 gearbox | purpose: speed increaser | Rratio: 1:1.5, one:two, 1:two.5, one:three, 1:3.five, 1:3.eight |

| spare parts: with splined coupling | Warranty: available |

Merchandise Description

action up gearbox for tractor pto

Series obtainable:6001,6002,6003,6004,7001,7002,7003,7004,7105,7106,7107,…….

The Gearboxes are designed for connecting equipment pumps to farm tractor electrical power just take offs (PTO). Output speed of electrical power just take offs is 540rpm which can be when compared with the suitable working speeds of hydraulic pumps. Diverse input running speeds can also be suited,presented that the gearbox output velocity does not exceed 3000 rpm.

Housing

Made in shell-c EPT aluminum or in higher mechanical resistance c EPT iron.

Gears

Made in Metal UNI eighteen PCR M03.Stub tooth promise extremely higher resistance and operate quite quietly.

Shafts

Manufactured in metal UNI 16 CRN4.They are coupled with gears through splined components and are hence more suitable to stand the torques stated in the catalogue.

Torques

The torque figures described in the complex charts of all the PTO Gearboxes refer to ongoing obligation cycles. Torques under intermittent operating conditions can be exceeded by 20%.

Lubrication

SAE ninety equipment oil need to be place in the pto gearbox prior to use-you should notice we do not offer the gear oil and will not take duty for buyers not placing oil in. Modify the oil following the 1st sixty-eighty hours and then every single twelve months or 1500 hrs which ever fal EPT 1st.

Routine maintenance

Remember to examine the oil amount by means of the EPT oil window every fifty hrs. Operating temperatures should not exceed one hundred twenty levels celcius underneath continuos duty cycle.

Pump assembly

Pump assembly demands a fifty percent-coupling and a fitting flange according to certain requirements,when buying please specify flange and pump shaft kind.Contact our technical personnel when setting up EPT pumps.

High China best quality China best supplier precision helical gear wheel shaft prices

assures the security and regularity of the essential function of elements.

Overview

Rapid Details

- Relevant Industries:

-

Manufacturing Plant

- Gearing Arrangement:

-

Worm

- Item Identify:

-

Helical gear charges

- Number of Enamel:

-

twelve – 150

- Optimum Enamel Breadth:

-

180mm

- Variety of Helix Angle:

-

±45°

- Module Assortment:

-

.5mm – four.0mm

- Accuracy Class:

-

Up to DIN Course 4 / ISO Class 4 / GB Class 4

Supply Capacity

- Source Capacity:

- 50000 Piece/Items for each Thirty day period

Packaging & Delivery

- Packaging Specifics

- Cartons and Picket Instances

- Port

- Ningbo/Shanghai

On-line Customization

| Substantial precision helical gear wheel shaft rates |

Q1. How to choose a worm travel servo which fulfills our requirement?

A1: You can refer to our catalogue to select the gearbox or we can aid to choose when you give

the technological info of output torque, output pace and motor parameter and many others.

Q2. How is your value? Can you offer you any low cost?

A2: We will give the ideal price tag we can foundation on your needs and the portions.

Q3. Do you supply any going to?

A3: Of course! We sincerely invite you to check out us! We can pick you from airport, railway station and so on.

Also, we can arrange housing for you. Remember to let us know in advanced.

This autumn. When is the ideal time to speak to you?

A4: You can contact us by email any time, we will reply you as shortly as feasible.

Q5. How extended will it just take for the lead time?

A5: For our normal model, remember to refer to the diverse item pages to examine the lead time.

For the OEM/ODM merchandise, you should contact us for even more data.