Product Description

Product Description

DO NOT worry about PRICE, we are manufacturer.

DO NOT worry about QUALITY, we have 16 years experience.

DO NOT worry about AFTER-SALES, we are 24 hours online.

Features :

1. The main body is made of high strength aluminum alloy

2. Zero backlash, suitable for forward and reverse rotation

3.Colloid is made of polyurethane, which has good wear resistance

4.Oil resistance and electrical insulation, the middle elasticbody can absorb vibration

5. Compensate radial, angular and axial deviations

6. Removable design for easy installation

7. Tightening method of positioning screw

Suitable for a wide range of devices

CNC lathes Optical inspection equipment

Module slider Servo motor

Company Profile

Certifications

Packaging & Shipping

All products will be well packed with standard export wooden case or

cartons.

Shafts packed with paper tube or plastic bag;

Linear guideways or lead screwswrapped with film or plastic bag;

Guarantee well protected against dampness,moisture, rust and shock.

Our Advantages

FAQ

Q1: Do you have a catalogue? Can you send me the catalogue to have a check of all your products?

A: Yes , We have product catalogue.Please contact us on line or send an Email to sending the catalogue.

Q2: I can’t find the product on your catalogue, can you make this product for me?

A: Our catalogue shows most of our products,but not all.So just let us know what product do you need.

Q3 : Can you make customized products and customized packing?

A: Yes.We made a lot of customized products for our customer before.And we have many moulds for our customers already.About customized packing,we can put your Logo or other info on the packing.There is no problem.Just have to point out that ,it will cause some additional cost.

Q4: Can you provide samples ? Are the samples free ?

A: Yes,we can provide samples.Normally,we provide 1-2pcs free samples for test or quality checking.But you have to pay for the shipping cos.If you need many items, or need more qty for each item,we will charge for the samples.

Any requirements or question,Welcome to “Send” us an e-mail Now!

It’s our great honor to do services for you! You also can get the FREE SAMPLES soon.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Applications of Helical Couplings in Various Industries

Helical couplings find wide use in numerous industries and applications due to their versatility, reliability, and ability to handle misalignment and transmit torque:

- Manufacturing: Helical couplings are used in CNC machines, mills, lathes, and other manufacturing equipment to ensure precise power transmission and minimize vibration.

- Robotics: Robotic arms and joints often employ helical couplings to connect motors and actuators, allowing for flexibility while maintaining accurate motion control.

- Medical Equipment: Imaging devices, surgical robots, and medical equipment often use helical couplings to ensure precise movement and positioning.

- Aerospace: Helical couplings are used in aerospace applications such as satellite systems, UAVs, and aircraft systems where lightweight yet durable coupling solutions are required.

- Automotive: Helical couplings find use in automotive testing equipment, vehicle assembly lines, and robotics for manufacturing and testing automotive components.

- Packaging and Conveyors: Packaging machinery, material handling systems, and conveyors utilize helical couplings to ensure efficient and accurate movement of products.

- Printing: Printers and labeling machines benefit from helical couplings’ ability to handle misalignment and transmit motion accurately.

The broad range of applications highlights the adaptability and reliability of helical couplings across various industries.

Considerations for Choosing a Helical Coupling for Your Application

When selecting a helical coupling for a specific application, several key factors should be considered:

- Torque Capacity: Determine the maximum torque that the coupling will need to transmit in your application. Choose a coupling with a torque capacity that exceeds the application’s requirements.

- Shaft Size: Ensure that the coupling’s bore size matches the diameter of the shafts to be connected. Proper sizing prevents slippage and ensures efficient torque transmission.

- Angular Misalignment: Evaluate the degree of angular misalignment that the coupling needs to accommodate. Different couplings have varying angular misalignment capabilities.

- Radial Misalignment: Consider the amount of radial misalignment that the coupling must handle. Choose a coupling that can accommodate the expected radial displacement.

- Axial Misalignment: If there will be axial movement between the shafts, select a coupling that can handle the required axial displacement without binding.

- Environmental Conditions: Take into account the operating environment, including temperature, humidity, dust, and chemical exposure. Choose a coupling material that is suitable for the conditions.

- Speed: Determine the rotational speed of the shafts. Ensure that the chosen coupling is rated for the application’s speed without causing resonance or vibration issues.

- Backlash: Assess the acceptable level of backlash in your application. Some couplings have minimal backlash, which is critical for precision applications.

- Cost: Consider the budget for your project. While it’s important to choose a reliable coupling, also balance the cost with the performance requirements.

By carefully evaluating these factors and consulting with coupling manufacturers or experts, you can choose the right helical coupling that meets the needs of your specific application.

Recent Advancements in Helical Coupling Technology

Recent years have seen several advancements and innovations in helical coupling technology, aimed at improving performance, reliability, and ease of use:

- Advanced Materials: Manufacturers are using innovative materials that offer enhanced strength, durability, and resistance to wear, allowing helical couplings to handle higher torque loads and harsh environments.

- Customization: Modern helical couplings can be designed and manufactured with greater customization options to fit specific application requirements, such as unique shaft sizes or complex misalignment conditions.

- Compact Designs: Engineers have developed more compact helical coupling designs that are lightweight and have a smaller footprint, making them ideal for space-constrained applications.

- Improved Torsional Stiffness: Innovations in coupling design have led to improved torsional stiffness, providing better control over torsional vibrations and ensuring precise power transmission.

- Integrated Monitoring: Some advanced helical couplings come with built-in sensors or monitoring systems that can provide real-time data on coupling performance, allowing for predictive maintenance and reducing downtime.

- Enhanced Tolerance for Misalignment: New designs allow helical couplings to handle higher levels of misalignment without sacrificing performance, making them more versatile for various applications.

These advancements continue to make helical couplings a reliable and versatile choice for a wide range of mechanical systems across industries.

editor by CX 2024-05-15

China manufacturer Ld Diaphragm Speed Reducer Screw Group Helical Drive Flexible Coupling for Encoder Shaft Coupling Dimensions

Product Description

Product Description

DO NOT worry about PRICE, we are manufacturer.

DO NOT worry about QUALITY, we have 16 years experience.

DO NOT worry about AFTER-SALES, we are 24 hours online.

Features :

1. The main body is made of high strength aluminum alloy

2. Zero backlash, suitable for forward and reverse rotation

3.Colloid is made of polyurethane, which has good wear resistance

4.Oil resistance and electrical insulation, the middle elasticbody can absorb vibration

5. Compensate radial, angular and axial deviations

6. Removable design for easy installation

7. Tightening method of positioning screw

Suitable for a wide range of devices

CNC lathes Optical inspection equipment

Module slider Servo motor

Company Profile

Certifications

Packaging & Shipping

All products will be well packed with standard export wooden case or

cartons.

Shafts packed with paper tube or plastic bag;

Linear guideways or lead screwswrapped with film or plastic bag;

Guarantee well protected against dampness,moisture, rust and shock.

Our Advantages

FAQ

Q1: Do you have a catalogue? Can you send me the catalogue to have a check of all your products?

A: Yes , We have product catalogue.Please contact us on line or send an Email to sending the catalogue.

Q2: I can’t find the product on your catalogue, can you make this product for me?

A: Our catalogue shows most of our products,but not all.So just let us know what product do you need.

Q3 : Can you make customized products and customized packing?

A: Yes.We made a lot of customized products for our customer before.And we have many moulds for our customers already.About customized packing,we can put your Logo or other info on the packing.There is no problem.Just have to point out that ,it will cause some additional cost.

Q4: Can you provide samples ? Are the samples free ?

A: Yes,we can provide samples.Normally,we provide 1-2pcs free samples for test or quality checking.But you have to pay for the shipping cos.If you need many items, or need more qty for each item,we will charge for the samples.

Any requirements or question,Welcome to “Send” us an e-mail Now!

It’s our great honor to do services for you! You also can get the FREE SAMPLES soon.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Industry Standards and Guidelines for Helical Couplings

While there are no specific industry standards dedicated solely to helical couplings, their design and application are influenced by general coupling standards and guidelines:

- AGMA Standard: The American Gear Manufacturers Association (AGMA) provides guidelines and standards related to couplings, including helical couplings. Their standards cover aspects like design, selection, and application considerations for flexible couplings.

- ISO Standards: The International Organization for Standardization (ISO) also offers standards related to flexible couplings. ISO standards provide recommendations for design principles, performance characteristics, and testing procedures.

- Manufacturer Recommendations: Coupling manufacturers often provide specific guidelines for the design, installation, and maintenance of their products. These recommendations are based on engineering principles and practical experience.

When designing and using helical couplings, engineers should consider these industry standards and guidelines to ensure proper performance, reliability, and safety. Adhering to recognized standards helps ensure that helical couplings are selected, installed, and operated correctly in various mechanical systems.

Utilization of Helical Couplings in Mechanical Systems

A helical coupling, also known as a beam coupling, is a type of flexible coupling that is used in mechanical systems to transmit torque and motion between shafts while accommodating misalignment. Here’s how it is utilized:

Helical couplings consist of two hubs, each with helical slots that interlock with the other hub’s slots. The interlocking design allows for flexibility in multiple directions while maintaining torsional rigidity.

When utilized in mechanical systems:

- Misalignment Compensation: Helical couplings can handle angular, axial, and parallel misalignments between shafts. The helical slots provide flexibility, allowing for small amounts of misalignment without transmitting excessive stress to connected components.

- Torque Transmission: Helical couplings transmit torque from one shaft to another while minimizing backlash. The helical slot design distributes torque evenly across the coupling’s surface, ensuring efficient power transmission.

- Reduced Vibration: The helical design of the coupling helps absorb shocks and vibrations, contributing to smoother operation and reduced wear on connected components.

- Compact Design: Helical couplings have a compact and lightweight design, making them suitable for applications with limited space.

- Simple Installation: These couplings are relatively easy to install, with minimal maintenance requirements.

- Various Applications: Helical couplings are commonly used in robotics, motion control systems, CNC machines, and other applications where precision and flexibility are essential.

In summary, helical couplings provide an effective solution for transmitting torque and motion between shafts while accommodating misalignment and reducing vibrations in various mechanical systems.

Impact of Design and Pitch on Helical Coupling Performance and Reliability

The design and pitch of helical couplings play a crucial role in determining their performance and reliability:

Design: The design of a helical coupling includes factors such as the number of helical elements, their shape, and the arrangement of the helix angles. A well-designed helical coupling can provide a balance between torsional stiffness and flexibility. A higher number of helical elements can increase the coupling’s torsional stiffness, making it more suitable for applications that require precise torque transmission. On the other hand, a lower number of helical elements can enhance flexibility and misalignment compensation.

Pitch: The pitch of a helical coupling refers to the distance between successive helical threads. A smaller pitch results in a finer thread, offering higher torsional stiffness and accuracy in torque transmission. Couplings with a smaller pitch are often preferred for applications with precise positioning requirements. Conversely, a larger pitch provides more flexibility and misalignment compensation, making it suitable for applications with dynamic loads and vibrations.

Choosing the appropriate design and pitch depends on the specific application requirements. Applications demanding high torsional stiffness and accurate torque transmission may benefit from a coupling with a smaller pitch and more helical elements. Meanwhile, applications involving misalignment accommodation and dynamic loads may favor a larger pitch and fewer helical elements to maintain flexibility and shock absorption.

Ultimately, a well-matched design and pitch ensure that the helical coupling can effectively balance the need for torque transmission, misalignment compensation, and resilience to varying operating conditions, contributing to its overall performance and reliability in mechanical systems.

editor by CX 2024-04-10

China manufacturer Ld Diaphragm Speed Reducer Screw Group Helical Drive Flexible Coupling for Encoder Shaft Coupling Dimensions

Product Description

Product Description

DO NOT worry about PRICE, we are manufacturer.

DO NOT worry about QUALITY, we have 16 years experience.

DO NOT worry about AFTER-SALES, we are 24 hours online.

Features :

1. The main body is made of high strength aluminum alloy

2. Zero backlash, suitable for forward and reverse rotation

3.Colloid is made of polyurethane, which has good wear resistance

4.Oil resistance and electrical insulation, the middle elasticbody can absorb vibration

5. Compensate radial, angular and axial deviations

6. Removable design for easy installation

7. Tightening method of positioning screw

Suitable for a wide range of devices

CNC lathes Optical inspection equipment

Module slider Servo motor

Company Profile

Certifications

Packaging & Shipping

All products will be well packed with standard export wooden case or

cartons.

Shafts packed with paper tube or plastic bag;

Linear guideways or lead screwswrapped with film or plastic bag;

Guarantee well protected against dampness,moisture, rust and shock.

Our Advantages

FAQ

Q1: Do you have a catalogue? Can you send me the catalogue to have a check of all your products?

A: Yes , We have product catalogue.Please contact us on line or send an Email to sending the catalogue.

Q2: I can’t find the product on your catalogue, can you make this product for me?

A: Our catalogue shows most of our products,but not all.So just let us know what product do you need.

Q3 : Can you make customized products and customized packing?

A: Yes.We made a lot of customized products for our customer before.And we have many moulds for our customers already.About customized packing,we can put your Logo or other info on the packing.There is no problem.Just have to point out that ,it will cause some additional cost.

Q4: Can you provide samples ? Are the samples free ?

A: Yes,we can provide samples.Normally,we provide 1-2pcs free samples for test or quality checking.But you have to pay for the shipping cos.If you need many items, or need more qty for each item,we will charge for the samples.

Any requirements or question,Welcome to “Send” us an e-mail Now!

It’s our great honor to do services for you! You also can get the FREE SAMPLES soon.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Endurance of Helical Couplings for High Torque and Axial Motion

Helical couplings are designed to withstand a range of mechanical forces, including high levels of torque and axial motion:

- High Torque: Helical couplings are capable of transmitting high levels of torque due to their robust construction and the interlocking helical teeth. The helical design enhances the coupling’s ability to handle torque without compromising flexibility.

- Axial Motion: Helical couplings can accommodate limited axial motion without compromising their performance. This is especially beneficial in applications where shafts might experience slight axial displacement due to thermal expansion or other factors.

Engineers select helical couplings based on the anticipated torque requirements and axial motion characteristics of the application. It’s important to ensure that the selected coupling has the necessary torque rating and axial flexibility to meet the demands of the specific machinery or system.

The Role of Helical Flexibility in Compensating for Shaft Misalignment

Helical couplings are designed with helical cuts or grooves in their construction. This helical design provides flexibility, allowing the coupling to compensate for various types of shaft misalignment:

- Angular Misalignment: The helical cuts enable the coupling to flex in response to angular misalignment between the connected shafts. As the misaligned shafts rotate, the helical flexure allows them to maintain contact and transmit torque effectively.

- Radial Misalignment: Helical couplings can also accommodate radial misalignment by flexing slightly in response to the offset between the shafts. This flexibility prevents binding or excessive forces on the shafts, reducing wear and extending the coupling’s lifespan.

- Axial Misalignment: While not all helical couplings can handle significant axial movement, some designs offer limited axial compensation. The helical flexure allows a small amount of axial displacement without compromising coupling integrity.

Overall, the helical flexibility of these couplings allows them to maintain constant contact and torque transmission even when shafts are not perfectly aligned. This feature enhances the coupling’s reliability, reduces stress on the connected components, and contributes to the longevity of both the coupling and the machinery.

Best Practices for Lubricating and Preserving the Performance of Helical Couplings

Lubrication is crucial for maintaining the performance and longevity of helical couplings. Here are some best practices to consider:

- Choose the Right Lubricant: Select a lubricant that is compatible with the materials of the coupling and provides adequate protection against wear and corrosion.

- Regular Lubrication: Follow the manufacturer’s guidelines for lubrication intervals. Regularly lubricate the coupling to ensure proper operation and prevent excessive wear.

- Clean Before Lubrication: Clean the coupling and the surrounding area before applying lubricant to prevent contamination.

- Apply the Right Amount: Apply the appropriate amount of lubricant as recommended by the manufacturer. Too much lubricant can lead to excess buildup and attract debris.

- Distribute Evenly: Ensure that the lubricant is evenly distributed across the coupling’s surfaces to provide effective lubrication.

- Monitor Performance: Regularly monitor the coupling’s performance for any signs of increased friction or abnormal operation that may indicate the need for relubrication.

- Inspect for Wear: During maintenance checks, inspect the coupling for signs of wear, corrosion, or damage. Replace the coupling if necessary.

- Protect Against Contaminants: Shield the coupling from dust, dirt, and other contaminants that can degrade the lubricant and cause premature wear.

- Environmental Considerations: If the machinery operates in extreme temperatures, wet or corrosive environments, choose a lubricant that can withstand these conditions.

- Follow Manufacturer’s Recommendations: Always follow the manufacturer’s recommendations for lubrication, maintenance, and storage to ensure optimal coupling performance.

By adhering to these best practices, you can maximize the efficiency, reliability, and lifespan of helical couplings in various mechanical systems.

editor by CX 2024-04-04

China manufacturer & factory supplier for EPT in Santa Cruz Bolivia R Series Helical Gear Parallel Shaft Speed Reducer With high quality best price & service

ISO 9001:2000 & AS 9100B qualified custom made manufacturer of roller chains. Specifications of roller chains consist of .1475 in. to .3750 in. pitch, 5.9 in. to 35.4 in. length, 180 lbs. to 1529 lbs. tensile load ability & .035 lbs. to .276 lbs. fat/ft. We are aiming to satisfy the demands of the customers close to the planet.. a specialized provider of a complete assortment of chains, sprockets, gears, gear racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….

Overview

Swift Specifics

- Relevant Industries:

-

Building Materials Stores, Manufacturing Plant, Equipment Mend Retailers

- Gearing Arrangement:

-

Helical

- Output Torque:

-

Max. 50000N.m

- Input Velocity:

-

1440rpm

- Output Pace:

-

eight-300rpm

- Location of Origin:Zhejiang, China

- Model Name:

-

OEM

- Model Number:

-

FR

- Rated Electrical power:

-

.twelve-200KW

- Product Name:

-

R Sequence Helical Gear Parallel Shaft Pace Reducer

- Mounting Situation:

-

As Essential

- Warranty:

-

12 Months

- Certificate:

-

CE ISO9001

Supply Potential

- Offer Capacity:

- 200000 Piece/Parts per Calendar year

Packaging & Supply

“EPG” manufacturer rotocultivator ploughshares in T.S. complete lines developed in our manufacturing facility have been tested and appraised by the Ministry of Agriculture and have received the license of popularizing farm equipment promulgated by the Ministry of Agriculture of the People’s Republic Worm gears are typically created by hobbing with a hob or cutting tool extremely related to the worm that the gear mates with. The worm might be turned, hobbed, milled, or floor.of China.

- Packaging Details

- Normal export packing and wood pallet packing

- Port

- SHANGHAI or NINGBO Port

Online Customization

We get a good deal of queries bordering PTO shafts and how to connect them to your tractor. In today’s post, we’ll protect the principles of PTO, PTO Shafts, and PTO adapters for your tractor mounted implements. PTO stands for “Power Take-Off” and is the main system for offering energy to an attachment or employ (these kinds of as a flail mower) by way of PTO shaft.By supplying rotational strength by way of the driveshaft (or cardan shaft) a range of tractor mounted implements can be operated by little and mid-sized tractors.

Exceptional Attributes of R Collection Helical Gear Parallel Shaft Pace Reducer

– F Sequence Decelerator is characterised by compact construction, mild bodyweight, large torque and excellent overall performance

– It is created of rib-bolstered rigid situation and quality alloy-metal gear which is hardened by carbon penetration and grinned specifically

– Secure in running, low sound, massive in load, lower in consumption, productive in transmission, reduced in temperature rise, and lengthy in service existence

– The mounting designs are footing, flange, torque arm and so on. The output design are shaft, hollow shaft, the alpine and shrink disc are for selection.

Images of R Collection Helical Equipment Parallel Shaft Velocity Reducer

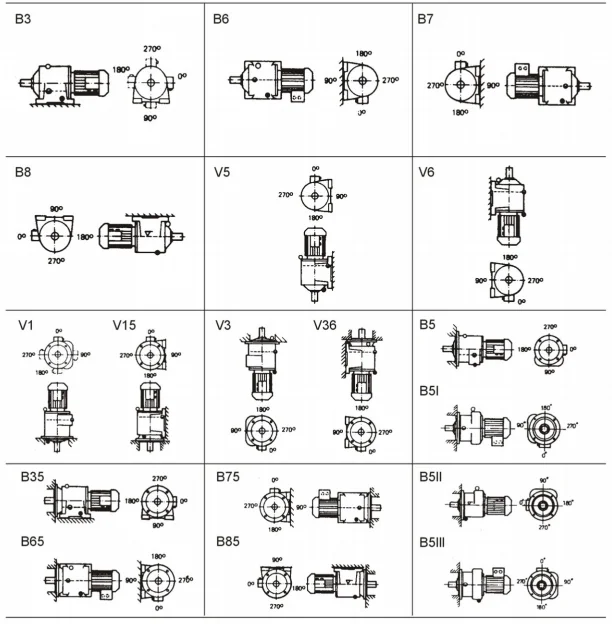

Different Mounting Postion of R Collection Helical Gear Parallel Shaft Velocity Reducer

Packing Images of R Series Helical Equipment Parallel Shaft Pace Reducer

Internal Packing: PP bag with carton

Outer Packing: Wood scenario

Shipment: fourteen-20 days on obtaining the deposit.

We can make four hundred,000 units of worm gearboxes, 100,000 units of gear reducers, 50,000 units of other speed reducers, one hundred fifty,000 models of flexible couplings, and a hundred,000 units of pace-reducer equipment every single year.

70% of our products have been exported to 40 much more international locations, and our buyers appear from Italy, Germany, Usa, Canada, Spain, United kingdom, India, Mexico, Brazil, Argentina, Turkey, Singapore and other major industrial countries. 30% of them are OEM made for direct producers of other items.

Q1. Is your high quality excellent?

A1: High quality in no way explain to lies, we are the largest maker and exporter of worm gear reducer in Asia, the very first reducers and gearboxes maker in China, who has been given license since 1993. Also, we experienced accomplished ISO9001 and CE Certificate amongst all companies.

Q2. How is your price? Can you provide any price reduction?

A2: We will give the best cost we can base on your wants and the quantities.

Q3. Do you offer you any visiting?

A3: Yes! We sincerely invite you to pay a visit to us! We can select you from airport, railway station and so on. Also, we can arrange housing for you. Remember to let us know in advanced.

This fall. When is the best time to make contact with you?

A4: You can speak to us by e-mail any time, we will reply you ASAP. If you want speak to by cellphone, our operating hour is Mon-Sat 9am-seventeen:30pm.

At any time_power Group

Tackle: No.789-B8Shenhua Road, XiHu Dsitriction Enco&Tech Advancement Zone HangZhou Town, ZJ, P.R.

Tel: 0086-571-88220971/Mob: +86 13083988828

WhatsApp/Skype: +86 13083988828

Internet site: www.hzpt.com

Best China manufacturer & factory For South Africa hydraulic reducer parallel shaft reduction zq 350 zq350 speed gearbox for ceramic industry With high quality best price

We inspect every piece of bearing by ourselves before delivery.

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant

Our products are selling well in Chinese markets and some products sold in international markets are well received by Chinese and foreign clients at home and abroad.

- Brand Name:

-

OEM

- ITEM NO:

-

SYF

- Model Number:

-

JZQ

- Product name:

-

JZQ gear box

- Product Keywords:

-

gearbox for metal flattening machine

- Color:

-

Green;Blue;Custom

- ZQ Reducer gearbox:

-

ZQ Reducer

- gearbox:

-

Reducer gearbox

- gearbox for material:

-

gearbox for dryer

- Gear speed reducer:

-

Zq gear speed reducer

- Material:

-

45C Steel

Packaging & Delivery

-

Lead Time

: -

Quantity(Pieces) 1 – 50 >50 Est. Time(days) 20 To be negotiated

Online Customization

Product Description

ZQ Cylindrical gear reducer gear carburizing, quenching, grinding, high bearing capacity, low noise; mainly used for belt conveyor and various kinds of transport machinery, can also be used to drive other general machinery. It has the advantages of high bearing capability, long service life, small volume, high efficiency, light weight, for the input shaft and the output shaft is vertically arranged in the driving device.

The field of cylindrical gear reducer is widely used in metallurgical equipment, mining equipment, automation equipment, food machinery, packaging equipment, tobacco equipment etc..

|

Specification |

ManufThe EPG Group of Companies (The EPG Group) manufactures, services and sells a wide range of capital plant equipment to a diverse range of industries. This includes the mining sector, processing, material handling, power generation and oil and gas refineries. To these sectors we provide services such as material handling, geotechnical instrumentation, boiler cleaning technology and engineering consultancy services, amongst others.acturing Capacity(t/h) |

Motor Power (kw) |

Pulley Speed (r/min) |

Gearbox Model |

Weight(t) |

|

Φ0.6×8 m |

1.5-2.8 |

4 |

8 |

JZQ 250-16- Ⅰ |

5.1 |

|

Φ0.8×10 m |

3 |

4 |

7.5 |

JZQ 350-16- Ⅰ |

6.9 |

|

Φ10×10 m |

3.3-4.9 |

5.5 |

5.8 |

JZQ 400-16- Ⅰ |

7.5 |

|

Φ1.2×10 m |

4-6 |

7.5 |

4.8 |

ZL 50-16- Ⅰ |

13.5 |

|

Φ1.5×12 m |

4-6 |

10 |

4.8 |

JZQ 500- Ⅲ-2F |

18.9 |

|

Φ1.5×15 m |

7-12 |

18.5 |

4.8 |

ZQ 500- Ⅲ-2F |

21 |

|

Φ1.8×12 m |

7-12 |

18.5 |

4.1 |

JZQ 50-16 Ⅱ-2 |

22.83 |

|

Φ2.2×12 m |

12 |

18.5 |

3.2 |

JZQ 650- Ⅲ |

37.6 |

|

Φ2.2×14 m |

12 |

22 |

3.2 |

JZQ 650- Ⅲ |

40 |

|

Φ2.2×16 m |

10-13 |

30 |

3.2 |

JZQ 750- Ⅲ |

45 |

|

Φ2.4×14 m |

10-14 |

30 |

3 |

JZQ 750- Ⅲ |

51 |

|

Φ2.4×18 m |

25 |

37 |

3 |

ZL85-13-Ⅰ |

54 |

|

Φ2.4×20 m |

32-36 |

37 |

3 |

ZL 85-13- Ⅰ |

54.14 |

|

Φ3×20 m |

40-50 |

55 |

2.59 |

ZL 100-16- Ⅰ |

78 |

|

Φ3×25 m |

45-58 |

75 |

2.59 |

ZL 100-16-I |

104.9 |

Zq Cylindrical gear speed reducer

Zq Cylindrical gear speed reducer is a three-level transmission of involute cylindrical gear reducer, mainly used inmining, metallurgy, cement, construction, chemical industry, light industry, etc all kinds of mechanical equipment, reduction drive, is suitable for the workplace being limited by the structure adopts the vertical installation, high-speed spindle speed not more than 1500 r/min, the work environment to + 40 °C and 40 °C -, can positive &negative operation.

Main Features

1.gear with high strength and low carbon alloy steel by carburizing quenching, tooth surface hardness of HRC58-62, gear are CNC grinding process, high precision, good contact.

2.transmission rate is high: single stage is greater than 96.5%, double stage is greater than 93%, grade three is greater than 90%.

3.stable operation, low noise.

4.small size, light weight, long service life, high carrying capacity.

5.easy to be disassembled and easy to install.

Our Company

HangZhou EPT GROUP – one of the biggest gearbox manufacturer in China – Electromechanical Facilities Co. Ltd

HangZhou EPT GROUP – one of the biggest gearbox manufacturer in China – Electromechanical Equipment Co., Ltd.is a gift enterprise integrating development, design, production and sales,Main promoting products include reducer motor,water pump,construction machinery and parts,bearings,hardware and electrical equipment,plastic products,Labour protection appliance.Our company always follow the operation concept which contains people-oriented, innovation as the soul,be prepared for ….

Application area

Certifications

Sales territory

Packing & Delivery

|

Packaging |

|

|

Size |

500 (L) * 500 (W) * 400 (D) |

|

Weight |

1.2 T |

|

Packaging Details |

The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request. |

|

Packaging |

|

|

Size |

500 (L) * 500 (W) * 400 (D) |

|

Weight |

1.2 T |

|

Packaging Details |

The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to cuThe star tube is suitable for applications with high torque peaks that could be harmful to the other tube shapes. The star tube with 6 contact points is also the preferred choice when transmissions exceed 1600mm in length and when the speed is 1000 rpm. AG series with splined tube The splined tube is suggested for very short PTO shafts. The splined telescopic shaft allows bushing and splined couplings of only 100-120mm. The dimensions of the cross joints vary from 22mm diameter up to 48mm diameter and allow power transmission of up to 250HP.stomers special request. |

FAQ

Q1: Are you trading company or manufacturer ?

A: We are a manufacturer in ZheJiang China.welcome to our factory to have a visit.

Q2: How we select models and specifications?

A:You can email us the series name & code (for example: WJ series worm gearbox) as well as requirement details, such as motor power, output speed or ratio, service factor or your application…as much data as possible. If you can supply some pictures or drawings, it is better.

Q3: How is your price? Can you offer any discount?

A: We will give the best price we can base on your needs and the quantities.

Q4: How long should I wait for the feedback after I send the enquiry?

A: Within 12 hours.

Q5: What is your product warranty period?

A:We offer one year warranty since the vessel departure date left China.

Q6: What industries are your gearboxes being used?

A:Our gearboxes are widely applied to metallurgical equipment, mining equipment, automation equipment, food machinery, packaging equipment, tobacco equipment and so on.

Contact us

Mobile: +86-13083988828 we chat # or 0086-571-88220971 (WeChat)

E-mail:hzptcorp (a) gmail.com

Fox:+86-571-88220972

Add:No.789 ShenHua Road, , XiHu District, HangZhou, ZheJiang, China

HangZhou EPT GROUP – one of the biggest gearbox manufacturer in China – Electromechanical Facilities Co. Ltd.