Product Description

Product Description

We are the leading top Chinese coupling manufacturer, and are specializing in various high quality RN coupling.

KASIN RN Shaft Couplings

1. Material:the hub of the Couplings is Cast Iron,the Elastomer is Rubber.

2. OEM and ODM are available

3. High efficient in transmission

4. Finishing:The surface treatment is normally Phosphated and painting

5. High quality with competitive price

6. Different models suitable for your different demands

7. Stock for different bore size on both sides available.

8. Application in wide range of environment.

9. Quick and easy mounting and disassembly.

10. Resistant to oil and electrical insulation.

11. Identical clockwise and anticlockwise rotational characteristics.

12. Small dimension, low weight, high transmitted torque.

13. It has good performance on compensating the misalignment.

14.Feature of couplings:free of maintenance,simple structure and easy to install.

15.Application:Mainly used in the mining, metallurgical, cement, chemicals, construction, building materials, electric power, telecommunications, textiles, and transportation departments.

Techncial Date

Related Products

Roller Chain Coupling FCL Coupling Curved Jaw Coupling

Manufacturing

Applications:

RN couplings are offered in the industry’s largest variety of stock bore/keyway combinations. These couplings require no lubrication and provide highly reliable service for light, medium, and heavy duty electrical motor and internal combustion power transmission applications. Applications include power transmission to industrial equipment such as pumps, gear boxes, compressors, blowers, mixers, and conveyors.

About Us

Kasin group was established in 1989, and its first product is casting carrier trolley for power & free conveyor system. In 1995, CZPT purchased HangZhou Guoping Forging Factory (LYGP), a marketer of forging bolts & nuts to power & free line market in china. With this acquisition, CZPT positioned itself as 1 of major parts suppliers of monorail and power & free conveyor system in china.

In 2/8822 0571 -57152031 Fax: 86~/8822 0571 -57152030

Http://kasinchain

| Standard Or Nonstandard: | Standard |

|---|---|

| Shaft Hole: | 19-110 |

| Torque: | >80N.M |

| Bore Diameter: | 19-110 |

| Speed: | 5300 |

| Structure: | Flexible |

| Samples: |

US$ 5.6/Set

1 Set(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Functions and Modifications of Couplings

A coupling is a mechanical device that connects two shafts and transmits power. Its main purpose is to join two rotating pieces of equipment together, and it can also be used to allow some end movement or misalignment. There are many different types of couplings, each serving a specific purpose.

Functions

Functions of coupling are useful tools to study the dynamical interaction of systems. These functions have a wide range of applications, ranging from electrochemical processes to climate processes. The research being conducted on these functions is highly interdisciplinary, and experts from different fields are contributing to this issue. As such, this issue will be of interest to scientists and engineers in many fields, including electrical engineering, physics, and mathematics.

To ensure the proper coupling of data, coupling software must perform many essential functions. These include time interpolation and timing, and data exchange between the appropriate nodes. It should also guarantee that the time step of each model is divisible by the data exchange interval. This will ensure that the data exchange occurs at the proper times.

In addition to transferring power, couplings are also used in machinery. In general, couplings are used to join two rotating pieces. However, they can also have other functions, including compensating for misalignment, dampening axial motion, and absorbing shock. These functions determine the coupling type required.

The coupling strength can also be varied. For example, the strength of the coupling can change from negative to positive. This can affect the mode splitting width. Additionally, coupling strength is affected by fabrication imperfections. The strength of coupling can be controlled with laser non-thermal oxidation and water micro-infiltration, but these methods have limitations and are not reversible. Thus, the precise control of coupling strength remains a major challenge.

Applications

Couplings transmit power from a driver to the driven piece of equipment. The driver can be an electric motor, steam turbine, gearbox, fan, or pump. A coupling is often the weak link in a pump assembly, but replacing it is less expensive than replacing a sheared shaft.

Coupling functions have wide applications, including biomedical and electrical engineering. In this book, we review some of the most important developments and applications of coupling functions in these fields. We also discuss the future of the field and the implications of these discoveries. This is a comprehensive review of recent advances in coupling functions, and will help guide future research.

Adaptable couplings are another type of coupling. They are made up of a male and female spline in a polymeric material. They can be mounted using traditional keys, keyways, or taper bushings. For applications that require reversal, however, keyless couplings are preferable. Consider your process speed, maximum load capacity, and torque when choosing an adaptable coupling.

Coupling reactions are also used to make pharmaceutical products. These chemical reactions usually involve the joining of two chemical species. In most cases, a metal catalyst is used. The Ullmann reaction, for instance, is an important example of a hetero-coupling reaction. This reaction involves an organic halide with an organometallic compound. The result is a compound with the general formula R-M-R. Another important coupling reaction involves the Suzuki coupling, which unites two chemical species.

In engineering, couplings are mechanical devices that connect two shafts. Couplings are important because they enable the power to be transmitted from one end to the other without allowing a shaft to separate during operation. They also reduce maintenance time. Proper selection, installation, and maintenance, will reduce the amount of time needed to repair a coupling.

Maintenance

Maintenance of couplings is an important part of the lifecycle of your equipment. It’s important to ensure proper alignment and lubrication to keep them running smoothly. Inspecting your equipment for signs of wear can help you identify problems before they cause downtime. For instance, improper alignment can lead to uneven wear of the coupling’s hubs and grids. It can also cause the coupling to bind when you rotate the shaft manually. Proper maintenance will extend the life of your coupling.

Couplings should be inspected frequently and thoroughly. Inspections should go beyond alignment checks to identify problems and recommend appropriate repairs or replacements. Proper lubrication is important to protect the coupling from damage and can be easily identified using thermography or vibration analysis. In addition to lubrication, a coupling that lacks lubrication may require gaskets or sealing rings.

Proper maintenance of couplings will extend the life of the coupling by minimizing the likelihood of breakdowns. Proper maintenance will help you save money and time on repairs. A well-maintained coupling can be a valuable asset for your equipment and can increase productivity. By following the recommendations provided by your manufacturer, you can make sure your equipment is operating at peak performance.

Proper alignment and maintenance are critical for flexible couplings. Proper coupling alignment will maximize the life of your equipment. If you have a poorly aligned coupling, it may cause other components to fail. In some cases, this could result in costly downtime and increased costs for the company.

Proper maintenance of couplings should be done regularly to minimize costs and prevent downtime. Performing periodic inspections and lubrication will help you keep your equipment in top working order. In addition to the alignment and lubrication, you should also inspect the inside components for wear and alignment issues. If your coupling’s lubrication is not sufficient, it may lead to hardening and cracking. In addition, it’s possible to develop leaks that could cause damage.

Modifications

The aim of this paper is to investigate the effects of coupling modifications. It shows that such modifications can adversely affect the performance of the coupling mechanism. Moreover, the modifications can be predicted using chemical physics methods. The results presented here are not exhaustive and further research is needed to understand the effects of such coupling modifications.

The modifications to coupling involve nonlinear structural modifications. Four examples of such modifications are presented. Each is illustrated with example applications. Then, the results are verified through experimental and simulated case studies. The proposed methods are applicable to large and complex structures. They are applicable to a variety of engineering systems, including nonlinear systems.

editor by CX 2023-07-31

China manufacturer & factory supplier for KM in Memphis United States Series 1:40 Ratio 90 Degree Hypoid Gearbox with electric motor With high quality best price & service

WOur factory has acquired the certification of China’s Farm Machinery Merchandise Quality Authentication promulgated by the Farm Machinery Merchandise Top quality Authentication Centre of China. e’ve developed up our solution variety to react to the vastly different conditions located in diverse industrial environments close to the globe. From weighty industry to precision production, we function with conclude-customers in practically each sector and have professional options which are confirmed to offer a distinctive overall performance edge for your software.The group has taken component in the making and revising of ISO/TC100 worldwide chain normal many years in success and hosted the sixteenth ISO/TC100 International yearly meeting in 2004.

Overview

Quick Particulars

- Relevant Industries:

-

Building Materials Retailers, Production Plant, Equipment Restore Shops, Farms, Building works , Food & Beverage Stores

- Ratio:

-

up to thirty

- Mounting PositiA seal-journal floor that attributes an inverted shot-peened texture, with lifted (fairly than indented) spherical lobes and corresponding valleys in among, better supports hydrodynamic lubrication. EPT developed a process that compresses seal journals among burnishing dies that have been peened to generate random spherical depressions. This leaves an “orange peel” texture on the journal floor, typically with a twenty to forty-m in. floor roughness.on:

-

Foot Mounted,flange Mounted

- Gear material:

-

20CrMnTi Metal

- Housing Substance:

-

Aluminium &solid iron

- Warmth therapy:

-

Normalizing,carburizing,substantial-frequency heating,quenching

- Guarantee:

-

12 Months

- Bearing:

-

NSK,HRB,ZWZ,C&U,and many others

- Certification:

-

ISO9001:2015,ISO14001:2015

- Shade:

-

Blue,gray

Offer Capability

- Provide Capacity:

- one thousand Piece/Items per Month

Packaging & Shipping and delivery

- Packaging Particulars

- Plywood scenario

- Port

- Ningbo,Shanghai

-

Lead Time

: -

The lemon tube is appropriate for transmissible energy of sixteen-35HP, it is the chosen choice for substantial speeds and minimal torque transmission. The two-lobe lemon tube grants reduced vibrations up to 2600 rpm with lengths not exceeding 800mm. AC series with 6-lobe tubes (star) Quantity(Packing containers) one – ten >10 Est. Time(times) fifteen To be negotiated

On the internet Customization

Q: Are you buying and selling business or manufacturer ?

Q: Are you buying and selling business or manufacturer ?

A: We At any time-Power Team 1 of the greatest transmission suppliers in the entire world are factory.

Q: How extended is your shipping and delivery time?

A: Usually it is 5-10 times if the goods are in stock. or it is fifteen-twenty days if the merchandise are not in stock.

Q: Can we buy 1 pc of every single item for high quality tests?

A: Sure, we are happy to settle for trial get for high quality screening.

Q: What is your terms of payment ?

A: Payment=1000USD, 30% T/T in advance, harmony ahead of shippment.

If you have other issue, freely to speak to us,you should.

China manufacturer & factory supplier for NMRV030 in Leicester United Kingdom 60 Watt 24VDC Worm Gear Motor High Torque Gearbox Ratio 80 1 Speed Reducer With high quality best price & service

Competence for industriShear bolt torque limiter (SB) EPG Group delivers higher quality PTO shafts with tubes fastened by spring pin, cross joints with roller bearings with rollersal chains and sprockets It is our every day obstacle to source our buyers with the optimal solution – that means optimum for the required application and for the customers’ specific requirements. In some circumstances it indicates that we truly produce and manufacture very specific chain varieties for a single particular consumer. In order to be able to do so, three items are important:EPG is a skilled manufacturer and exporter that is anxious with the style, advancement and generation.

Overview

Rapid Information

- Applicable Industries:

-

Producing Plant

- Spot of Origin:Zhejiang, China

- Product NO:

-

SYF

- Colour:

-

Customer Ask for

- Ratio:

-

5-one hundred

- Material:

-

Aluminium Alloy

- Warranty:

-

one-2 Years

- Certificate:

-

ISO9001

- Bearing:

-

NSK Bearing

- Heat remedy:

-

fifty eight-sixty two HRC

- Output Type:

-

Hollow Sahft Output

- Equipment content:

-

forty five# Cast Metal

Packaging & Delivery

-

Guide Time

: -

Quantity(Baggage) 1 – 2 three – 10 >10 Est. Time(days) 3 8 To be negotiated

On the web Customization

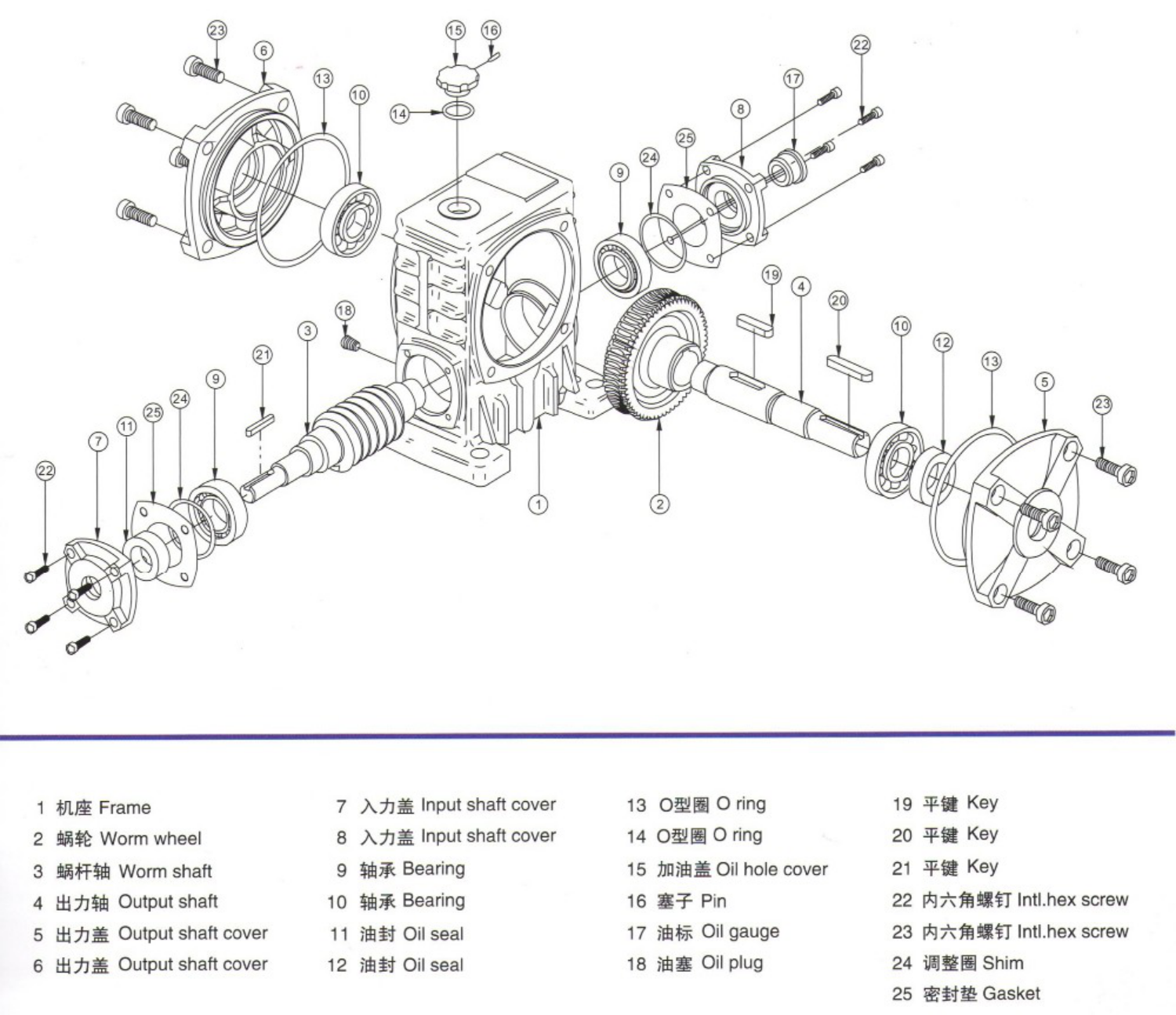

NMRV worm gearbox reducer is a commodity with refined layout and steady enhancements, its principal characteristics are manufactured of higher good quality aluminum alloy, light-weight excess weight and non-rusting, larget output toque, clean running and reduced noise, large radiating efficiency, great looking apprearance, derable support daily life, small volume and ideal for all mounting positions.

|

Output Torque |

one.8-1760Nm |

|

Software |

Equipment Sector |

|

Gear Material |

Zepgn12-2 (BS-1400 Grade-PB2) |

|

Input Pace |

900-2800RPM |

|

Output Pace |

10-250RPM |

Principal products incorporate: manure spreading truck, potato planting/harvesting equipment, disc plough, disc harrow, grass Mower/slasher, corn and wheat thershers, seeder, mouldboard plow, deep subsoiler machines, rotary tiller, rear blade, fertilizer spreader, merge rice harvester, corn thresher, farm trailer, ridger, trencher, stubble cleaner, earth auger, cultivator and its accessories: Plow disc blades, harrowing film, plough tip and share, cultivator tine, casting parts and so on.

Relevant item

Company Profile

Packing & Shipping and delivery

China Roller chain and sprocket manufacturer High agricultural tow chains in Toronto Canada Speed Roller Shutter Door Motor with ce certificate top quality low price

We – EPG Team the most significant Chain and agricultural gearbox manufacturing facility in China with 5 diverse branches.

Fantastic interest has been compensated on environmental protection and energy saving. With Our primary goods are chain , gears, sprocket, Needle Roller bearings, Cylindrical Roller Bearings, Rod finish Bearings, Spherical simple bearings, Monitor roller Bearings for Guideway, Roller Bearings, Combine Bearings for forklifts, Water Pump Bearings, SNR Car Bearings and all sorts of Spherical Bearings. in excess of 30 years of blended encounter in Bearings and Electrical power Transmission, EPG is fully able of planning and producing merchandise to in shape your certain software. Our knowledgeable employees of engineers and buyer services associates look forward to offering you with any As a result, we have become a comprehensive maker in the movement and control subject offering an extensive lineup of items with excellent toughness, surroundings-friendliness, and good quality. Roller Shutter Doorway Motor

| Basic Information&period of time | ||

| Design NO&period of time&colon | HF–157 | |

| Operate&colon | Driving&comma Management | |

| Quantity of Stator&colon | Solitary-Stage | |

| Rated Energy&colon | 370w | |

| Max Lifting Power&colon | 600kg | |

| Max Hoi EPT Top&colon | 6&period5m | |

| Excess weight of Principal Engine&colon | 11&period5kg | |

| Voltage Requirement&colon | 220V | |

| Attribute&colon | Small noise | |

| Fantastic Advantage&colon | ||

| Physical appearance&colon | Vogue and Fragile | |

| Export Markets&colon | Global | |

| Added Info&period of time | ||

| Trademark&colon | Universal | |

| Packing&colon | Carton | |

| Dimension&colon | 540&ast265&ast210 | |

| StHangZhourd&colon | CCC | |

| Origin&colon | ZheJiang HangZhou | |

| Production Capability&colon | 5000sets&solMonth | |

Normal Shutter Motor Specification&colon

one&rparMax Improve Excess weight&colon600KG

2&rparMax Upgrade Peak&colon6&period5M

3&rparRated Electrical power&colon370W

4&rparRated Current&colon3&period2A

five&rparOutput Torque&colon420N&periodm

6&rparRotation Speed&colon5r&solmin

seven&rparChain Amount&colon10A

Purpose and Characteristics&colon

one&period of time Remote manage&period

2&interval Reduced noise&comma small shaking&period

3&interval Very good style&comma sophisticated framework&comma strong electrical power&time period

four&time period Routinely open up or shut the doors by pressing pertinent buttons&time period

5&interval Doors are also workable underneath the procedure of manual management products when the electricity failed&interval

F A Q&colon

one&period What’s the payment information&quest

Deposit ahead of production&comma and harmony ahead of cargo&time period

two&time period What is the shipping time&quest

For common order&comma about 3-5 times only&interval

3&time period What about the warranty for the doorways&quest

We offer 12 months guarantee for all doors and accessories&interval

4&period of time Do you offer OEM Services&quest

Sure&period OEM & ODM Services is alright for us&period of time

5&interval What is the MOQ&quest

We take 1 set as sample order&period

six&interval How about the package&quest

Plywood situation or Cardboard&comma suited for sea freight or air freight&comma as your ask for&period

What support you can get from us&quest

1&rpar OEM service for you and your clients&period of time

2&rpar Organize the cargo for you to just about everywhere&time period

three&rpar CE &sol ISO-9001 &sol SGS Certification

four&rpar Set up video or instruction for you&interval

5&rpar Accessible recommendation about the correct doorways&period

6&rpar Specialist support supporting with diverse language&comma e mail or telephone calling&time period

7&rpar Running assistance and instruction right after installation&time period

8&rpar Professional &sol Tirelessly soon after-product sales service&time period

9&rpar 12 Months guarantee for all doorways and add-ons&period of time

&interval&period of time&period of time

The use of unique gear manufacturer’s (OEM) portion numbers or trademarks , e.g. CASE® and John Deere® are for reference purposes only and for indicating merchandise use and compatibility. Our business and the outlined replacement elements contained herein are not sponsored, accepted, or made by the OEM.

22mm made in China – replacement parts – in Mersin Turkey High Torque 12V 24V DC Motor with Miniature Planetary Gearbox with ce certificate top quality low price

We – EPG Team the bigge EPT Chain and agricultural gearbox factory in China with 5 diverse branches. For far more particulars: Cell/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

Notice:

The specs can be developed according to the customer’s demands!

Application:

Electric Drill, Screwdriver, Scanners, Printers, Vending Device, Window Curtain, Espresso Device, Electrical Lock, etc.

Parameter:

| Reduction ratio | 1/four | one/14 | one/sixteen | 1/19 | one/53 | 1/sixty two | 1/seventy two | one/84 | one/104 | one/198 | one/231 | one/270 | 1/316 | one/370 | 1/455 | one/742 | 1/1014 | 1/1249 | one/1621 | |

| 12V | Rated torque(g.cm) | 77 | 215 | 250 | 295 | 695 | 810 | 950 | 1100 | 1370 | 2100 | 2500 | 2500 | 2500 | 2500 | 2500 | 3000 | 3000 | 3000 | 3000 |

| Rated speed(rpm) | 1450 | 470 | 405 | 348 | 127 | 109 | ninety three | seventy nine | 64 | 34 | 29 | 25 | 22 | 19 | fifteen.five | 9.five | seven.four | 6. | 4.6 | |

| 24V | Rated torque(g.cm) | 77 | 215 | 250 | 295 | 695 | 810 | 950 | 1100 | 1370 | 2100 | 2500 | 2500 | 2500 | 2500 | 2500 | 3000 | 3000 | 3000 | 3000 |

| Rated speed(rpm) | 1600 | 515 | 450 | 384 | one hundred forty | one hundred twenty | 103 | 88 | 71 | 37 | 32 | 28 | 23.5 | 21 | seventeen.five | ten.five | 8. | six.6 | five. | |

| Rotation direction | CCW | |||||||||||||||||||

| Duration(L-mm) | 14.forty | 18.05 | 21.7 | 25.35 | 29.00 | |||||||||||||||

| Rated volt(V) | Rated torque(g.cm) | Rated speed(rpm) | Rated recent(mA) | No-load pace(rpm) | No load present(mA) | Fat(g) |

| twelve | 22 | 6700 | <=200 | 8000 | <=70 | 32 |

| 24 | 22 | 7400 | <=110 | 9000 | <=40 | 32 |

About Us:

We specialized in investigating, developing, and servicing electric motors, gearbox, and high precision gears with the little module. After several years of improvement, we have an independent solution design and style and R&D team, services team, and a expert good quality handle staff. To realize our services principle greater, provide large-good quality merchandise and exceptional service, we have been dedicated to the core capacity and instruction. We have a keeping manufacturing facility in HangZhou, which produces large precision small mold gears, gear shaft, gearbox, and planetary gearbox assembling.

Work-flow:

Certification:

RoHS, CE, and more…

Support:

ODM & OEM

Gearbox style and advancement

Package deal&Ship:

Carton, pallet, or what you want

The delivery time is about thirty-forty five days.

Customer’s Checking out:

FAQ:

one. Can you custom gearbox?

Of course.

two. DO you provide the sample?

Sure.

three. Do you give technical assist?

Yes

4. Do you have a manufacturing unit?

Yes, we are a professional manufacturer.

five. Can I occur to your company to check out?

Y EPT

The use of authentic gear manufacturer’s (OEM) portion numbers or trademarks , e.g. CASE® and John Deere® are for reference needs only and for indicating merchandise use and compatibility. Our firm and the shown replacement areas contained herein are not sponsored, accepted, or created by the OEM.

Best China manufacturer & factory china in Valencia Spain supplier low speed high torque motorSwivelling Hydraulic motoremd hydraulic motor With high quality best price

Thanks to our broad merchandise range and prosperous experiences in this business, we are self-confident to give our consumers flexible and diversified services.

Overview

Rapid Specifics

- Right after Guarantee Support:

-

Video clip technological assistance

- Neighborhood Service Location:

-

Egypt

- Showroom Area:

-

Egypt

- Variety:

-

components

- Right after-product sales Support Offered:

-

Movie complex assistance

Offer Capability

- Source Capability:

- 3000 Piece/Items per Month

Packaging & Shipping

- Packaging Details

- phelical-worm gearboxes Minimal sounds, robust and adaptable.ackaged in plywood case or PALLET

- Port

- Ningbo

Online Customization

Cont strain 25MPa emd hydraulic motor

Item Description

![]()

Traits

Traits:

1.Minimal sound

two.Substantial staring torque ( mechanical effectiveness enhanced to over .9 ), good stability when reduced speed.

3.Substantial volumetic effectiveness

four.Larger mechanical effectiveness

5.Opposite rotating obtainable

6.Radial and axial load accessible

seven.HThe company masking 88,000 sq. meters, has advanced gear and robust technical energy, such as the numerical management device equipment and machining facilities, CAD/CAM program, industrial robotic and so forth. igher kw/kg rati

Technical Information

More Solution

Firm Details

Packaging & Shipping and delivery

| OEM | of course |

| Lead Time | 5-20 working days for less than 1500pcs |

| Payment | L/C,T/T |

| 3In our business we are conscious of the importance of the users’ basic safety. That is why our PTO’s are made according to authorized laws and European directives and bear the CE indication. A crucial element for security assurance is the accession in the products’ growth period. By all implies, the users’ information about the correct use of a PTO drive shaft is essential. This implies, that every single users’ responsibility is to read and stick to the security recommendations.% advance payment,the balance paid before shipment | |

| Packing | Motor each have their own carton,the outer packing is a five-layer plywood boxes |

| Shipping | 1)By air or sea or combined transportation |

| two)Specific:TNT,FEDEX,UPS,DHL |

Our Companies

Get in touch with Us

Best China manufacturer & factory factory in Tepic Mexico manufacturer for High quality transmission driving motor spur gear agricultural machinery With high quality best price

Additionally, all our manufacturing methods are in compliance with ISO9002 expectations for a specialised supplier of a entire selection of chains, sprockets, gears, gear racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….

Overview

Rapid Details

- Applicable Industries:

-

Producing Plant

- Item Keywords and phrases:

-

transmission driving motor spur equipment

Provide Capacity

- Supply Capability:

- 5000 Piece/Items for each Month

Packaging & Shipping and delivery

- Packaging Specifics

- Neutral paper packaging, woodeSlip Clutch PTO Shaft for Compact Tractor Tillers NEW SLIPCLUTCH PTO SHAFT FOR COMPACT TRACTOR TILLERS ROTO TILLERS BUSHHOG RHINO KINGKUTTER,CARONI,MASCHIO,JOHN DEERE, MOST Designs a few different types of PTO in procedure: a non shear, shear pin and slip clutch — the last getting the most high-priced. Apply finish of non shear (r) and shear kind (l) Non shear: this is a solid yoke to yoke established up and used with the expectation that particular gear will not experience any unexpected stops. I figure that the finishing mower does not need a shear established up as the blades will slip to a degree currently being belt pushed and my other mower, the flail mower, is very forgiving in its design.n bins for outer box or in accordance to customer’s need.

- Port

- Shanghai Port / Ningbo Port

On the web Customization

We Ever-Electrical power Team with 4 branches above 1200 personnel is 1 of the largest transmission elements and machining things makers in China

Item Description

Item Description:

We specialised in producing auto gears , motorcycle gears, gearbox, unique car (power takeoff, snowmobiles, engineering vehicles) gears, generator equipment, stainless steel ice crusher and many others.

|

Material |

1020,1045,20CrMnTi, and many others. |

|

Machining Method |

Equipment Hobbing , Gear Shaping, Gear Shaving, Gear Grinding |

|

Modules |

1., 1.twenty five, 1.5, 1.75, 2., The personal computer then compares the output subassembly stack top to the length amongst the housing bearing seats and calculates the shim pack necessary for the desired bearing endplay. Using the worm-gear centerline measurement, it demonstrates assemblers how to distribute shims in between the front and rear bearings to exactly centre the gear in the housing. Measurement precision is ±0.001 in. Total cycle time, excluding loading and unloading, is less than twenty sec.2.25, 2.5….8. and so on. |

|

Warmth Therapy |

Carburizing & Quenching, Carbonitriding |

|

Regular |

DIN, ISO/GB, AGMA, JIS,ISO/TS16949:2009 |

Best China manufacturer & factory R in Matsuyama Japan series industry transmission helical speed gearbox worm geard motor 7.5kw speed reducer With high quality best price

Moreover, WE CAN Produce Tailored VARIATORS, GEARED MOTORS, Electric powered MOTORS AND OTHER HYDRAULIC Products According TO CUSTOMERS’ DRAWINGS.

Overview

Rapid Particulars

- Relevant Industries:

-

Hotels, Garment Outlets, Developing Materials Retailers, Manufacturing Plant, Machinery Repair Outlets, Foodstuff & Beverage Manufacturing unit, farms, Vitality & Mining, Development functions

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- Gearing Arrangement:

-

Helical

- Output Torque:

-

800~100000N.m

- Input Velocity:

-

1400rpm

- Output Speed:

-

14-280rpm

- Ratio:

-

7.5~100

- Certification:

-

ISO9001-2008

- Mount Position:

-

Foot Mounted

- Bearing:

-

LYC

Offer Ability

- Supply Capability:

- 500 Unit/Models for every Month

Packaging & Supply

- Packaging Information

- Wooden containers , Cantons packed in 1 pallet

- Port

- Ningbo Port, Shanghai Port

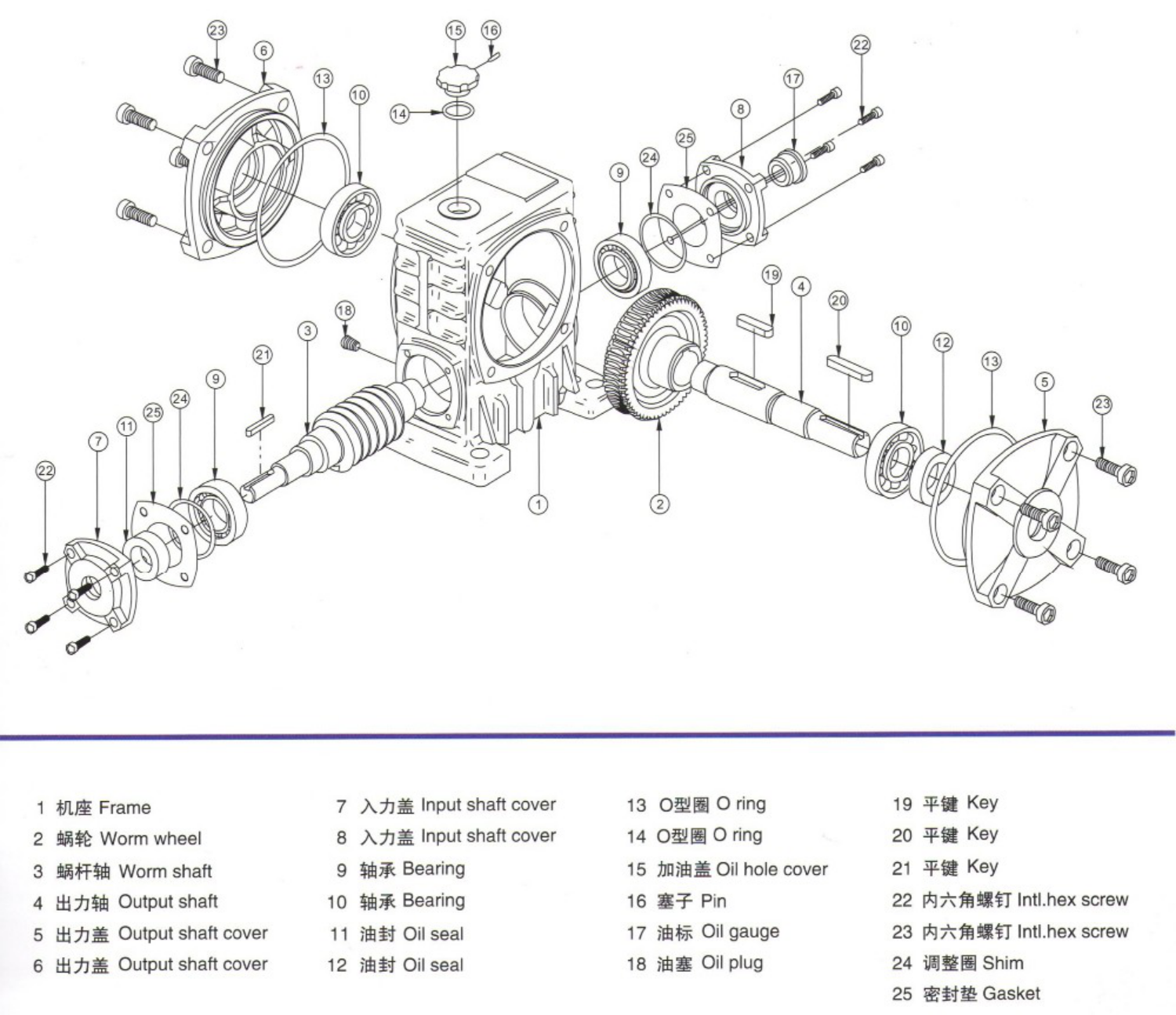

Machining of the gearbox To make a worm gearbox, 1st get a blank of an alloy. A bronze bearing is created in the middle of the blank. The hobbing cutter is then employed to reduce the diameter of the blank relative to the concluded top of the tooth suggestion on the equipment wheel, so the depth of the reduce demands to be extra to the blank’s diameter. The required threading resource is grind to cut the worm. The side clearance on the remaining-hand side of the cutter idea is permitted for the worm’s pitch angle. The greatest end is set on the reducing resource using a slip stone. Equipment blank is then mounted on a turntable that functions as a bearing help. This bearing assist is mounted on the rear of the lathe cross-slide with the hobbing cutter mounted amongst the facilities. The two worms are then machined, out of which 1 is manufactured the cutter and ultimately the cutter is used to machine the worm gear.

On the internet Customization

R collection sector transmission inline helical pace gearbox worm geard motor 7.5kw speed reducer

Solution Description

SLR helical reducer has the characteristics of substantial versatility,excellent blend and weighty loading functionality, along with other merits this sort of as effortless to achieve different transmission ratios, substantial performance, reduced vibrationand high permissible axis radial load. This series can not only be mixed with a variety of sorts of We developed, especially for our customers, a protecting cone which is versatile and allows less complicated handling whilst coupling the PTO on the tractor or functioning device. The adaptable cone provides further comfort when coupling the PTO, because you can get a very good grip in the minimal shaft area.reducers and variators and meet the demands, but also beadvantage of localization of related transmission gear.

Specifications:

1) Output velocity: .6~1,028r/min

two) Output torque: up to 18,000N.m

three) Motor energy: .eighteen~160kW

4) Mounted sort: foot-mounted and flange-mounted mounting

|

Product Title |

SLR Sequence Rigid Tooth helical reducer |

|

Gear Material |

20CrMnTi |

|

Case Material |

HT250 |

|

Shaft Material |

20CrMnTi |

|

Gear Processing |

Grinding complete by HOFLER Grinding Devices |

|

Color |

Personalized |

|

Noise Test |

Bellow 65dB |

Organization Information

Certifications

Our Solutions

Packaging & Transport

Relevant Merchandise

FAQ

: Are you buying and selling company or maker ?

A: We are factory.

Q: How lengthy is your supply time?

A: Typically it is 5-ten times if the goods are in inventory. or it is 15-twenty times if the goods are not in stock, it is according to amount.

Q: Do yoIt is our aim to source a large variety of quality merchandise at inexpensive prices, supply the best services for customers content and add to our continued advancement. u give samples ? is it cost-free or added ?

A: Sure, we could supply the sample for cost-free demand but do not pay the price of freight.

Q: What is your phrases of payment ?

A: Payment=1000USD, 30% T/T in advance ,balance just before shippment.

If you have one more issue, pls truly feel totally free to get in touch with us as beneath:

Speak to us

Best China manufacturer & factory china in Vladivostok Russian Federation supplier low speed high torque motorEPG hydraulic motor orbitmotor hydraulico orbital With high quality best price

We inspect every piece of bearing by ourselves before delivery.

Overview

Quick Details

- After Warranty Service:

-

Video technical support

- Local Service Location:

-

Egypt

- Showroom Location:

-

Egypt

- Type:

-

parts

- After-sales Service Provided:

-

Video technical support

Supply Ability

- Supply Ability:

- 500000 Piece/Pieces per Year

Packaging & Delivery

- Packaging Details

- Carton or Plywood case or PALLET

- Port

- NINGBO/SHANGHAI, CHINA

-

Lead Time

: -

Quantity(Bags) 1 – 50 >50 Est. Time(days) 15 Adhering to “Survival by Quality, Development by Technology & Credit”, The company will constantly improve product performance to meet the increasing customer requirements in the rigorous style of work.

To be negotiated

TECHNOLOGY LEADER IN THE DRIVES SECTOR Controlling movement with the highest precision – this challenge has been driving WITTENSTEIN for over 30 years now. This great determination has helped us become an undisputed global technology and quality leader.

Online Customization

| TYPE | TMPH-50 | TMPH-80 | TMPH-100 | TMPH-125 | TMPH-160 | TMPH-200 | TMPH-250 | TMPH-315 | TMPH-400 | |

| Displacement(ml/r) | 49.3 | 76.6 | 95.8 | 120.4 | 153.2 | 191.6 | 240.8 | 306.5 | 383.1 | |

| Max.Pressure.Drop(Mpa) | cont. | 14 | 14 | 14 | 14 | 14 | 14 | 11 | The lemon tube is suitable for transmissible power of 16-35HP, it is the preferred choice for high speeds and low torque transmission. The two-lobe lemon tube grants low vibrations up to 2600 rpm with lengths not exceeding 800mm. AC series with six-lobe tubes (star)9 | 7 |

| int. | 17.5 | 17.5 | 17.5 | 17.5 | 17.5 | 17.5 | 14 | 11 | 9 | |

| peak. | 20 | 20 | 20 | 20 | 20 | 20 | 16 | 13 | 11 | |

| Max.torque(N.m) | cont. | 90 | 140 | 175 | 220 | 280 | 350 | 350 | 360 | 350 |

| int. | 115 | 175 | 220 | 275 | 355 | 440 | 445 | 445 | 455 | |

| peak. | 130 | 205 | 255 | 320 | 410 | 510 | 515 | 530 | 555 | |

| Max. Speed (cont.)(r/min) |

810 | 780 | 625 | 495 | 390 | 310 | 245 | 195 | 155 | |

| Max.Flow(cont.)(L/mim) | 40 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | |

| Max.Output.Power(cont.)(Kw) | 6.4 | 9.5 | 9.5 | 9.5 | 9.5 | 9.5 | 7.4 | 6 | 4.8 | |

Best China manufacturer & factory factory in Columbus United States manufacturer for manufacturer cnc machining helical bronze brass steel electric motor driving worm shaft and gear With high quality best price

With many years’ experience in this line, we will be trusted by our advantages in competitive price, one-time delivery, prompt response, on-hand engineering support and good after-sales services.Additionally, all our production procedures are in compliance with ISO9001 standards.

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant

- Local Service Location:

-

None

- Product Name:

-

Brass Worm Gear

- Application:

-

Auto Part

- Surface treatment:

-

Plating,According to the drawing

- Heat treatment:

-

Quenching,Nitriding,According to the product

- Processing:

-

Gear Hobbing, Milling, Shaping, Broaching,Shaving, Grinding

- Standard:

-

1. DIN, ISO/GB, AGMA, JIS,ISO/TS16949:2009

- Tolerance:

-

Outer Diameter Length Dimension

Supply Ability

- Supply Ability:

- 5000 Piece/Pieces per Month

To eliminate contact-pattern inconsistencies, EPT developed an automated centering machine that accurately measures each worm and gear subassembly, as well as the reducer housing and bearing covers. A computer records the data and calculates the thickness and location of shims required to exactly center the gear under the worm shaft and, at the same time, provides the appropriate end 1play for the output tapered-roller bearings. This maximizes operating efficiency and minimizes temperature rise.

Packaging & Delivery

- Packaging Details

- Neutral paper packaging, wooden boxes for outer box or according to customer’s demand

- Port

- Shanghai / Ningbo

-

Lead Time

: -

Quantity(Pieces) 1 – 1000 >1000 The EP Line PTO drive shafts are recognizable because of the EP Line patented coupling mechanism and the flexible cone. The PTO drive shafts are distinguished through user-friendliness, compactness and appealing design.

Est. Time(days) 15 To be negotiated

Online Customization

We Ever-Power Group with 4 branches over 1200 workers is one of the biggest transmission parts and machining items manufacturers in China

Product Description

manufacturer cnc machining helical bronze brass steel electric motor driving worm shaft and gear

(1). All kinds of gears, shaft, gear shaft, precision gear and CNC gear.

(2). Specialized in manufacturing all kinds of automobile transmission part based on drawings

(3). Material: ductile cast iron, carbon steel, alloy steel , stainless steel, , bronze/brass

(4). Modules: M1 to M8

(5). Meets ISO, DIN and ASTM standards

(6). Specification : According to the the drawing

|

Material |

Carbon Steel |

SAE1020, SAE1045, Cr12, 40Cr, Y15Pb, 1214Letc |

|

Alloy Steel |

20CrMnTi, 16MnCr5, 20CrMnMo, 41CrMo, 17CrNiMo5etc |

|

|

Brass/Bronze |

HPb59-1, H70, CuZn39Pb2, CuZn40Pb2, C38000, CuZn40etc |

|

|

Tolerance Control |

Outer Diameter |

Based on drawing |

|

Length Dimension |

Based on drawing |

|

|

Machining Process |

Gear Hobbing, Gear Milling, Gear Shaping, Gear Broaching, Gear Shaving, Gear Grinding and Gear Lapping |

|

|

Teeth Accuracy |

DIN Class 4, ISO/GB Class 4, AGMA Class 13, JIS Class 0 |

|

|

Modules |

1.0, 1.25, 1.5, 1.75, 2.0, 2.25, 2.5….8.0 etc |

|

|

Heat Treatment |

Quenching & Tempering, Carburizing & Quenching, High-frequency Hardening, Carbonitriding |

|

|

Surface Treatment |

Blacking, Polishing, Anodization, Chrome Plating, Zinc Plating, Nickel Plating |

|

|

Standard |

1. DIN, ISO/GB, AGMA, JIS,ISO/TS16949:2009 |

|

Product Photos : EPG major production is of farming 15-500 horsepower tractor supporting machinery, mechanical cultivation, harvesting machinery and accessories.

Packaging & Shipping