EPG is a professional manufacturer and exporter that is concerned with the design, development and production.

Overview

Quick Details

-

Applicable Industries:

-

Manufacturing Plant

-

Pole:

-

SIt is our aim to supply a vast range of quality products at affordable prices, provide the best service for customers satisfied and contribute to our continued improvement. ingle/Double/Three Stage Speed Reducer

-

Ratio:

-

8.23 – 48.57

-

Housing Material:

-

Cast Iron

-

Working temperature:

-

-40~45℃

-

Application:

-

mining, chemical industry,steel metallurgy,lifting transpor and ect.

-

Process:

-

Carburizing, Nitriding , Grinding

-

Efficiency:

-

94%~98%

-

Mounting Position:

-

Horizontal,Vertical,Flange

-

Color:

-

Blue,Green,Gray,Red

-

Type:

-

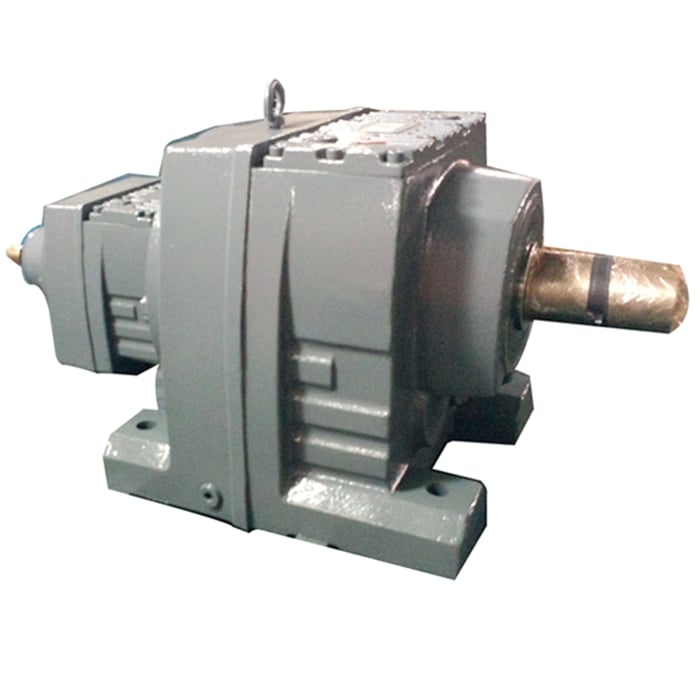

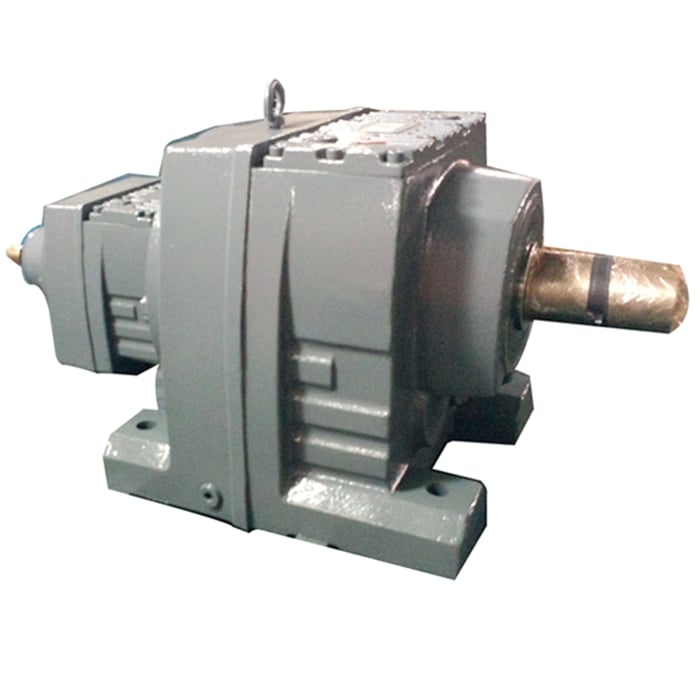

High torque ZS ZSC Series 3 stages cylindrical gear gearbox

Packaging & Delivery

-

Lead Time

:

-

| Quantity(Bags) |

1 – 1 |

>1 |

| Est. Time(days) |

15 |

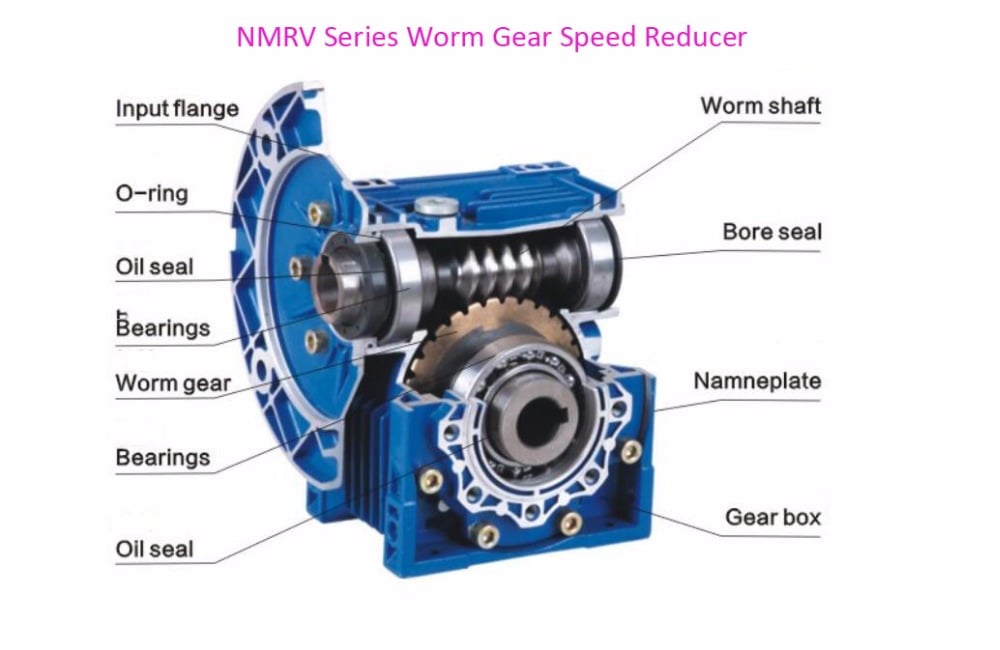

helical-worm gearboxes Low noise, robust and versatile.

To be negotiated |

Online Customization

Product Description

YOUR PROFESSIONAL MANUFACTURE

—— SINCE 1995

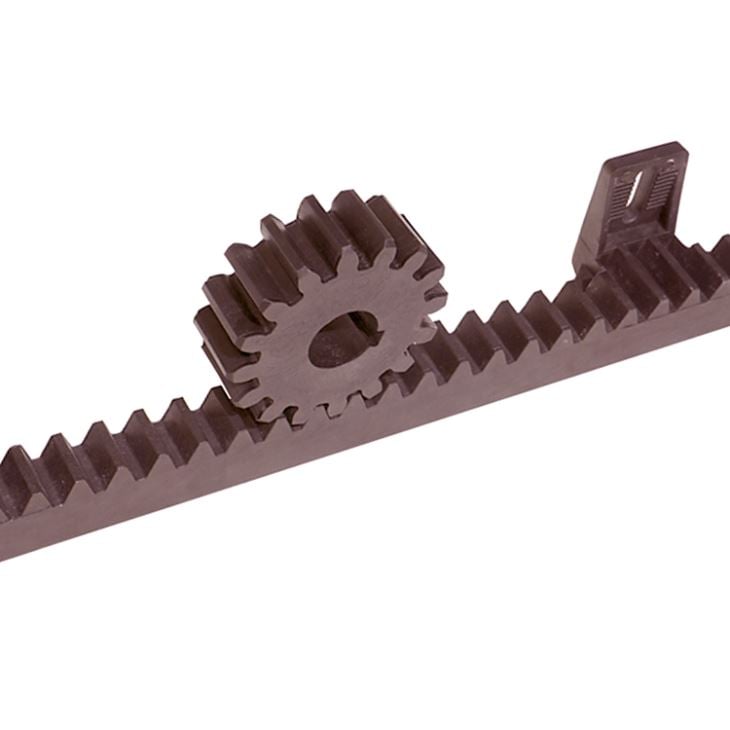

Z Series Helical Gear Reducer

Z (ZDY, ZLY, ZSY, and ZFY) serieshard tooth surface cylindrical gear reducer

D (DBY and DCY) series hard tooth surface cone gear reducer

EPG——industrial gearbox manufacturers

High torque ZS ZSC Series 3 stages cylindrical gear gearbox for wind turbine

Chinese electric motor speed reducer is widely used in mining machinery, chemical industry,steel metallurgy, light industry,environmental protection, paper making, printing, lifting transport, food industry and so on.

Main Series Product: R series helical gear reducer, K series spiral bevel gear reducer, NGW, P series planetary reducer, H B series gearbox, Z (ZDY, ZLY, ZSY, and ZFY) serial hard tooth surface cylindrical gear reducer, D (DBY and DCY) serial hard tooth surface cone gear reducer, cycloid reducer, etc. Meanwhile, map sample processing business can be undertaken.

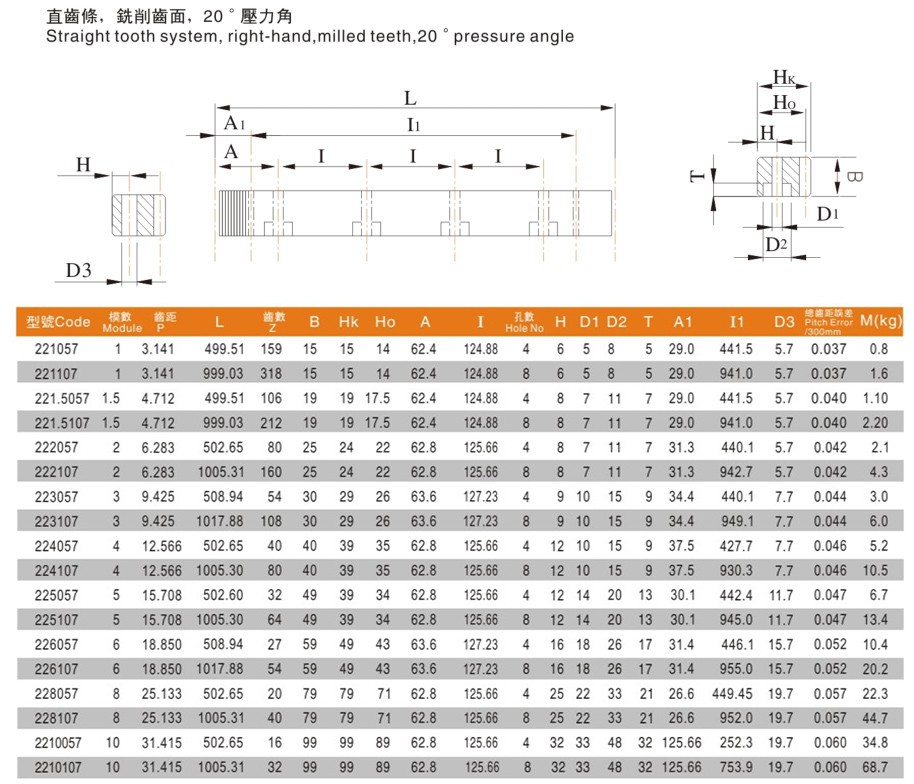

Specification

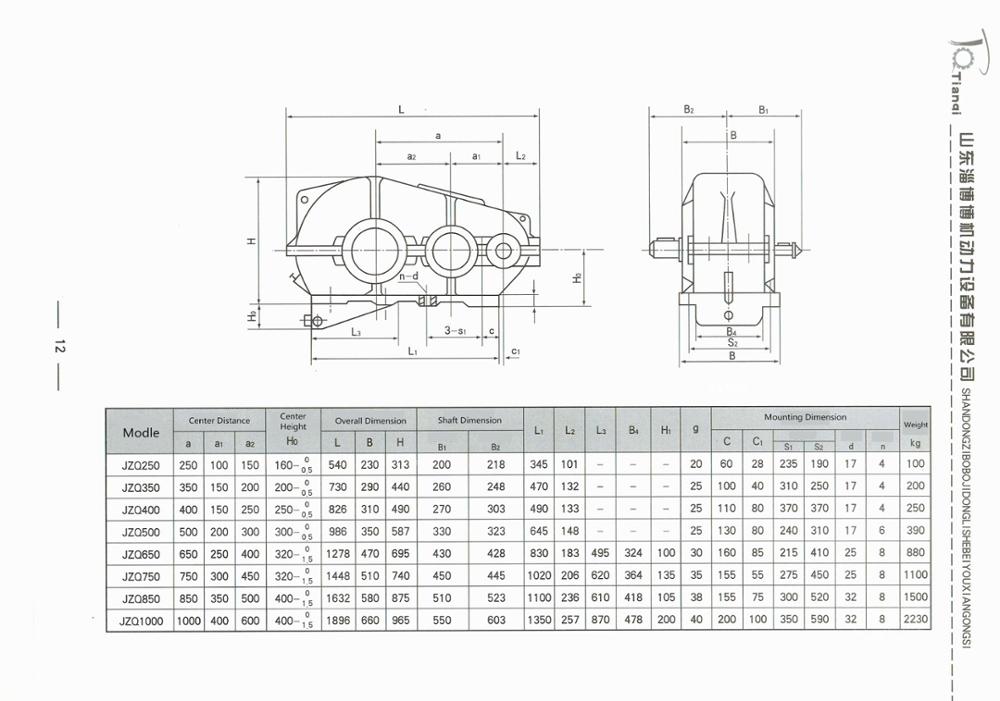

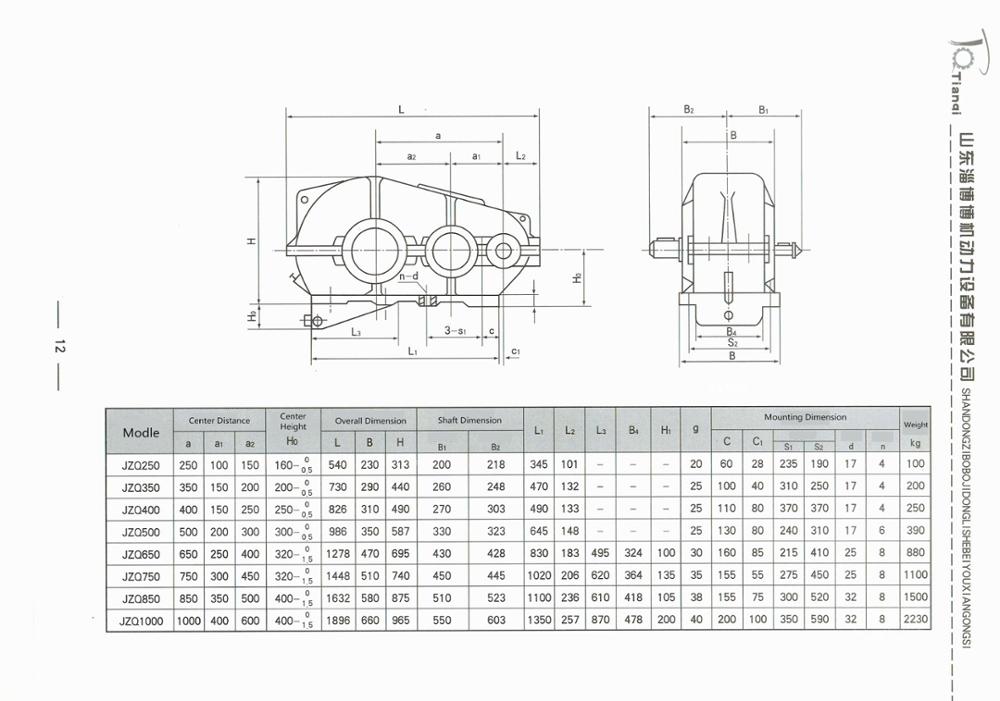

ZheJiang ZQD 3 stage higher ratio Gearbox speed reducer made in ZiBo:

(please contact us for more types & model) Mounting Diamensions

Model selection for gear box traAre you searching for a PTO water pump or PTO- driven generator? Hundreds of PTO parts from EPG mean you can find PTO shaft parts and accessories for whatever kind of equipment you’re working with. From PTO drive shafts to shield parts, we have dozens of replacement PTO parts. We stock Eurocardan parts as well as Neapco parts because those are names you can trust. Whether you need flex couplers or PTO shaft assemblies, we can help.nsmission:

Closely using the ideal reduction ratio.

Reduction ratio = servo motor speed / reducer output shaft speed

Torque calculation: Torque calculation is very important for the life of reducer, and pay attention to whether the maximum torque value (TP) of acceleration exceeds the maximum load torque of the reducer.

The applicable power is usually the applicable power of the servo models on the market, the applicability of the reducer is very high, the working coefficient can be maintained above 1.2, but the choice can also be based on their own needs to decide. High torque ZS ZSC Series 3 stages cylindrical gear gearbox for wind turbine.

| Driven machines |

| Waste water treatment |

Thickeners,filter presses,flocculation apparata,aerators,raking equipment,combined longitudinal and rotary rakes,pre-thickeners,screw pumps,water turbines,centrifugal pumps |

Dredgers |

Bucket conveyors, dumping devices, carterpillar travelling gears, bucket wheel excavators as pick up, bucket wheel excavator for primitive material, cutter head, traversing gears |

| Chemical industry |

Plate bending machines, extruders, dough mills, rubbers calenders, cooling drums, mixers for uniform media, agitators for media with uniform density, toasters, centrifuges |

Metal working mills |

plate tilters, ingot pushers, winding machines, cooling bed transfer frames, roller straigheners, table continuous intermittent, roller tables reversing tube mills, shears continuous, casting drivers, reversing blooming mills |

| Metal working mills |

Reversing slabbing mills. reversing wire mills, reversing sheet mills, reversing plate mill, roll adjustment drives |

Conveyors |

Bucket conveyors, hauling winches, hoists, belt conveyors, good lifts, passenger lifts, apron conveyors, escalators, rail travlling gears |

| Frequency converters |

Reciprocating compressors |

| Cranes |

Slewing gears, luffing gears, travelling gears, hoisting gear, derricking jib cranes |

Cooling towers |

Cooling tower fans, blowers axial and radial |

| Cane sugar production |

Cane knives, cane mills |

Beet sugar production |

Beet cossettes macerators, extraction plants, mechanical refrigerators, juice boilers, sugar beet washing machines, sugar beet cutter |

| Paper machines |

Pulper drives |

Cableways |

Material ropeways, continuous ropeway |

| Cement industry |

Concrete mixer, breaker, rotary kilns, tube mills, separators, roll crushers |

|

|

Technology

Chinese Speed Reducer is a mechanical transmission in many fields of the national economy. The product categories covered by the industry include all kinds of gear reducer, planetary gear reducer and worm gearbox, as well as various special transmission devices such as speed increasing device, speed control Devices, including various types of flexible transmission devices, such as compound transmission. Products and services in the field of metallurgy, nonferrous metals, coal, building materials, ships, water conservancy, electricity, construction machinery and petrochemical industries.

In all fields of national economy and national defense industry, gearbox products have a wide range of applications. Food light industry, electric machinery, construction machinery, metallurgy machinery, cement machinery, environmental protection machinery, electronic appliances, road construction machinery, water conservancy machinery, chemical machinery, mining machinery, conveyor machinery, building materials machinery, rubber machinery, petroleum machinery and other industries have strong demand of Reducer products. High torque ZS ZSC Series 3 stages cylindrical gear gearbox for wind turbine.

Packaging & Shipping

Company Information

Established in 1995 , HangZhou Ever-Power Machinery is a professional manufacturer and exporter that is concerned with the design, development and production of Gearbox Speed Reducer. We are located in HangZhou of ZheJiang Province, with convenient transportation access. With our own brand “EPG”, all of our products comply with international quality standards and are greatly appreciated in a variety of different markets throughout the world.

Our company possesses complete machining center, lathe, gear shaping machine, gear milling machine, gear grinding machine and assembling lines. Our well-equipped facilities and excellent quality control throughout all stages of production enables us to guarantee total customer satisfaction.

Besides, In 2005,we attained ISO9001 certification. As a result of our high quality products and outstanding customer service, we have gained a global sales network reaching South America, Saudi Arabia, Vietnam, Pakistan, Philippines, South Africa and other countries and regions.

With rich export experience, high quality products, competitive prices, good service and in-time delivery, we certain that we can meet all of your requirement and exceed your expectations. Our feature is bright with new cooperative relationships with companies from all over the world. We look forward to speaking with you to future discuss how we can be of service to you.

Our Services

FAQ

1.Q:Are you the factory or trading company?

A:We are the Factory, with 23 years of production experience.

2.Q:Can you customize according to our requirements?

A:Yes, we can design nonstandard products according to customer’s drawing and sample.

3.Q:How long is the delivery date?

A:10-20 working days. Cutomized type need to according to the quantity.

4.Q:Where is your factory?

A:We are in HangZhou of ZheJiang Province, you can get here by high speed train or fly to Jinan.

Welcome to visit us!

5.Q:What’s your payment terms?

A:TT 30% as deposite, 70% banlance paid before delivery.