The new products include a series of high-tech and high quality chains and sprockets and gears, such as chains and gearboxes for agricultural machineries, metallurgical chains, escalator step-chains, high-speed tooth chains, timing chains, self-lubrication chains, among which have type high speed tooth chain for car branch dynamic box and aerial chains fill in the blanks of chain in China.

Overview

Quick Details

-

Applicable Industries:

-

Manufacturing Plant

-

Teeth Type:

-

Spur gear or Helical gear

-

Heat treatment:

-

Teeth hardened HRC50-55

-

Module:

-

0.4-20

-

Our company is located in XiHu HangZhou Zhejiang Province. T Normal material:

-

20CrMnTi

-

More material:

-

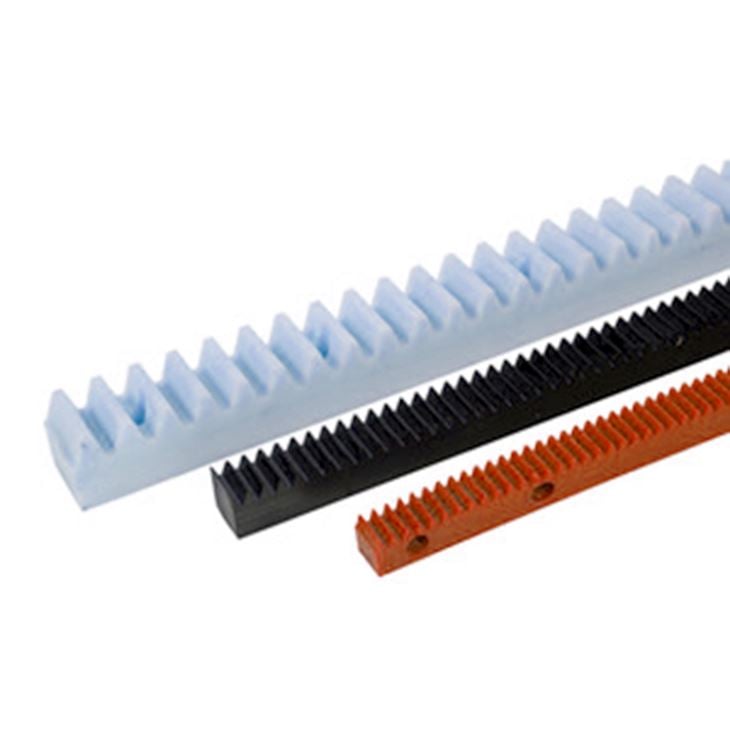

Steel, Stainless steel, brass, POM, Nylon etc.

-

Color:

-

Natural, black, galivanized etc.

-

Quality:

-

Teeth ground or not as request

-

Bore:

-

Ground

-

MOQ:

-

1 Pc

-

Service:

-

Reply in 12 hours at any time

Supply Ability

-

Supply Ability:

- 5000 Piece/Pieces per Month

Packaging & Delivery

- Packaging Details

- Antirust oil + paper bag + Wooden case

- Port

- Ningbo, Shanghai or as request

-

Lead Time

:

-

| Quantity(Bags) |

1 – 200 |

201 – 500 |

501 – 2000 |

>2000 |

| Est. Time(days) |

20 |

30 |

45 |

To be negotiated |

Online Customization

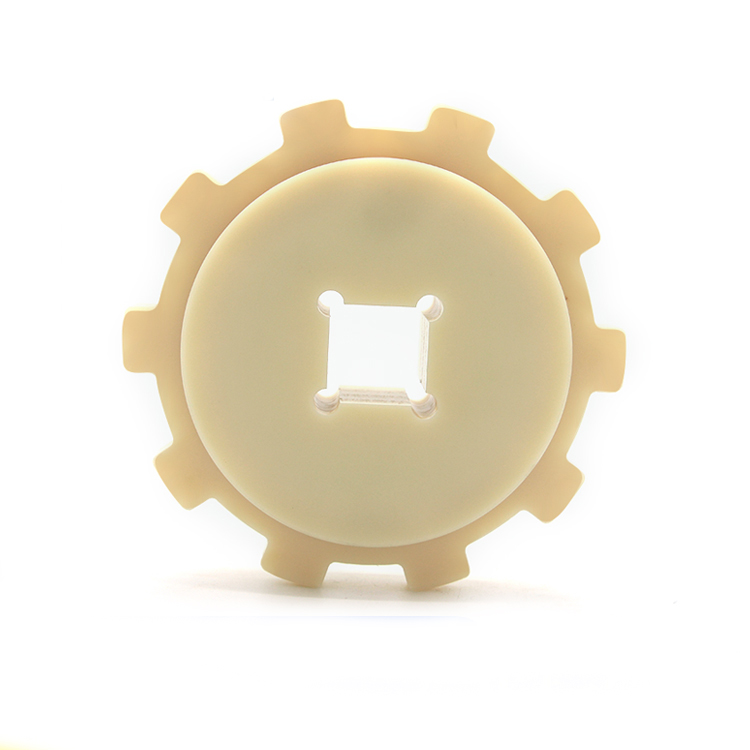

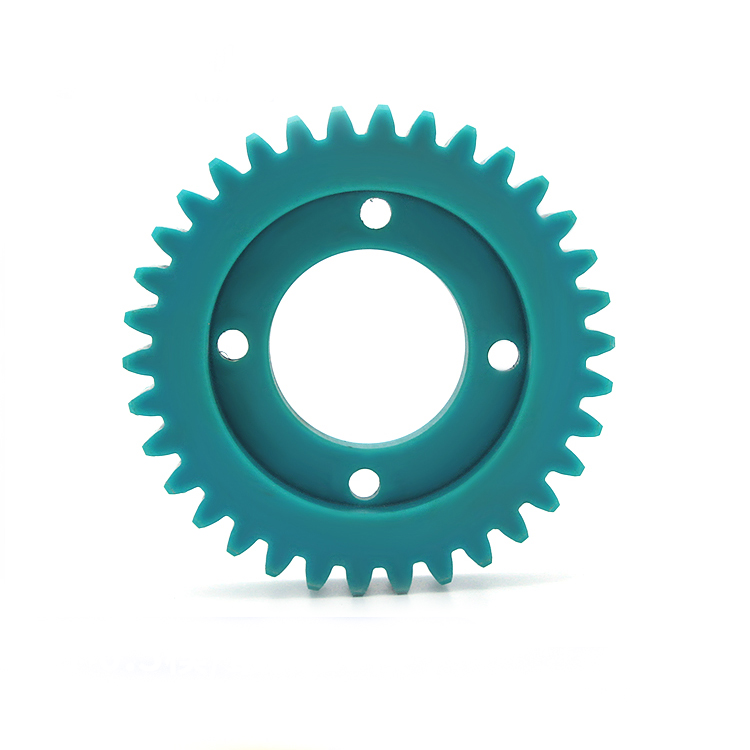

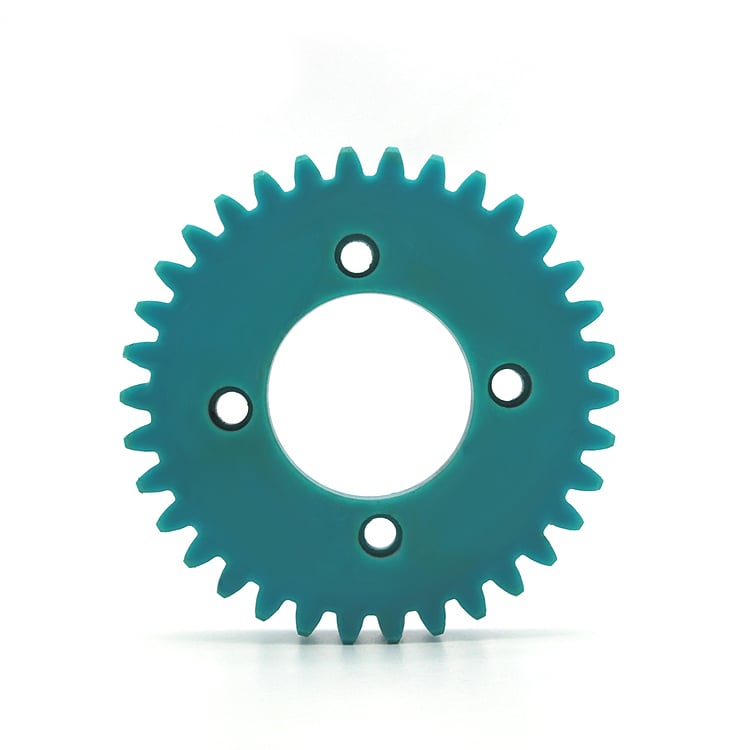

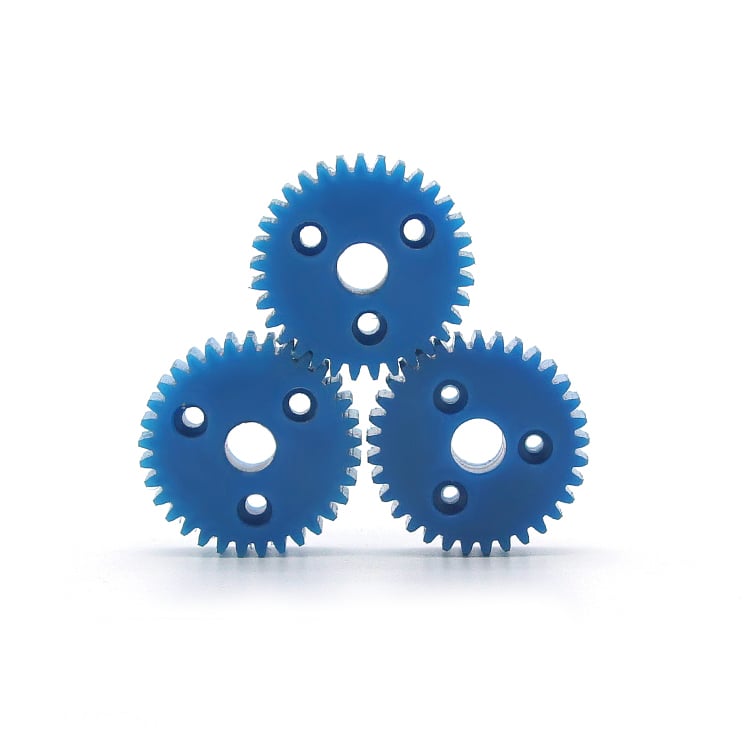

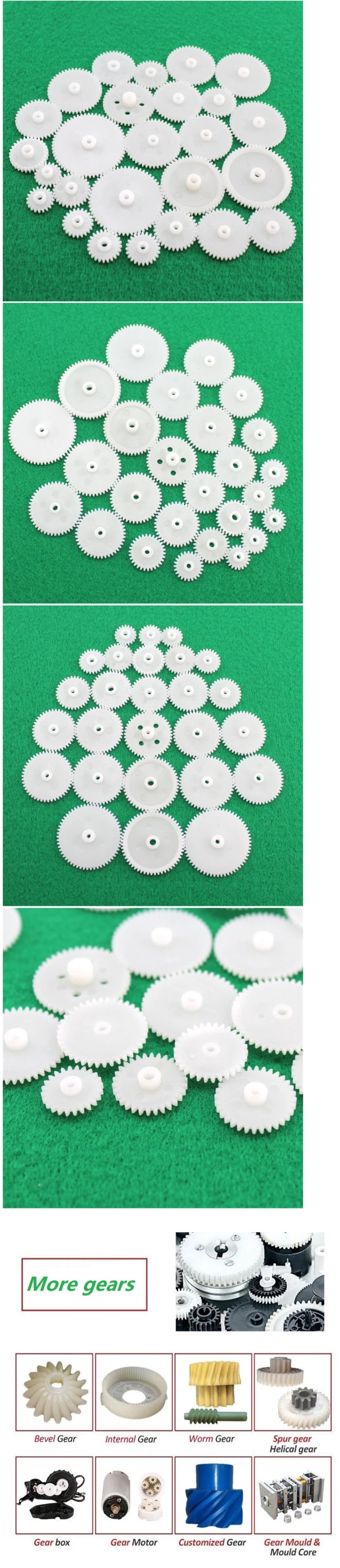

China precision metal steel drive gear and spur helical pinion gears

Product description

Our spur and helical gears are welcomed by many customers for its stable high quality and competitive price.

The producing character of JH gears:

1. Gear size: the biggest diameter is 1500mm;

2. Material: Most common steel is high strength steel 20CrMnTi. Others can be steel C45, stainless steel, high strength steel, copper, aluminium, plastic, POM etc;

3. Gear module: 0.3-8 (pitch from 0.942-25.12mm, DP 3.175-85);

4. Surface: zinc (galvanized), black, chromium plating, nickel plating, quenching and tempering etc.

5. Quality: stable and high, grade 7 for without teeth grinding, grade 6 after teeth grinding, grade 5 for precise grinding.

Prices for above quality are very competitive for us.

6. Heat treatmentThis way of working creates synergies between the different products; if we add a very dynamic and professional policy, the result is a high profitability in strategic deals, that warrants the benefit of our customers.: teeth can be hardened to HRC 55-63.

The quality character of JH gears:

1. Stable transmission and low noise;

2. Effectively avoid normal tolerance based on high precision;

3. The teeth can be ground to grade 6 and grade 5 quality;

4. The bore will be polished to smooth and high precision;

5. The price is competitive even the quality is high.

| Facilities |

Machining center;

CNC gear hobbing machine;

CNC gear shaper;

CNC gear grinding machine;

CNC turning machine;

CNC milling machine.

Y58200 CNC large gear rack shaper,

Y58125A gear rack shaper,

England gear rack shaper

and Russia gear rack shaper.

Gleason machine

|

| Gear types |

Helical gears (more and more widely used for its stable transimission);

Spur gears;

Hub gears;

Bevel gears;

Bevel spiral gears;

Gear ring; etc.

|

| Material |

Steel: C45, Q235, 40Cr, 20CrMnTi, etc.

Stainless steel: 301, 201, 304, 316 etc.

Brass: H59 H68 H80 H90 etc.

Aluminium: 6082, 6061, A380 etc.

Aluminium alloy: 6061, 5083, 7050, etc.

More: PA6, PA66, POM, ABS etc.

|

| Surface |

Polishing; Plating; Galvanized; Blacken; chromium plating, nickel plating; painting etc. |

Actual photos

Actual photos

Our Advantage is high quality gears:

grade 5-6 with teeth precise grinding.

Our Services

1. Delivery time: 15-25 days for small order;

The quality of products is for us and for our customers of high significance. This is why we use European made components in our products. We also perform constant control of incoming materials and the control of finished products. In our company we work according to ISO 9001. 30-45 days for big order. (Never delayed till now)

Can be discussed for more urgent order.

2. Response time: usually in 1 hour and in 12 hours even in our holidays.

3. Process feedback: Photos or vedios will be sent for 2-3 times to inform you the producing situation.

4. Test report: The test report can be offered as request.

5. Payment terms: T/T, L/C, D/P, D/A, O/A, M/T, D/D etc.

6. Trade terms: FOB, CFR, CIF, FCA, CPT, CIP, DDU, DDP etc.

Company Information

FAQ

Q: Manufacturer?

A: Yes. Since 2004 only focus on producing high quality gears and racks.

Q: Response time?

A: Reply very soon, and reply in 12 hours at any time.

Our technicians are always together with salesmen, so your any questions can be replied very soon.

Q: Price?

A: Drawings are more appriated for quotation. Or, please inform us your request, we will make drawings for your check.

Q: Delivery time?

A: 15-25 days for small order (<200 pcs), 30-45 days for large order.

Orders never be delayed, the products will be sent on time as agreement.

Q: Quality?

A: Middle and high quality is more competitive.

Q: Payment terms?

A: T/T for less than US$20,000 order, and L/C, D/P, D/A, O/A, M/T, D/D etc. for large orders.

Q: Trade terms?

A: FOB, CFR, CIF, FCA, CPT, CIP, DDU, DDP etc. are all accepted.

Hot related products

Contact us