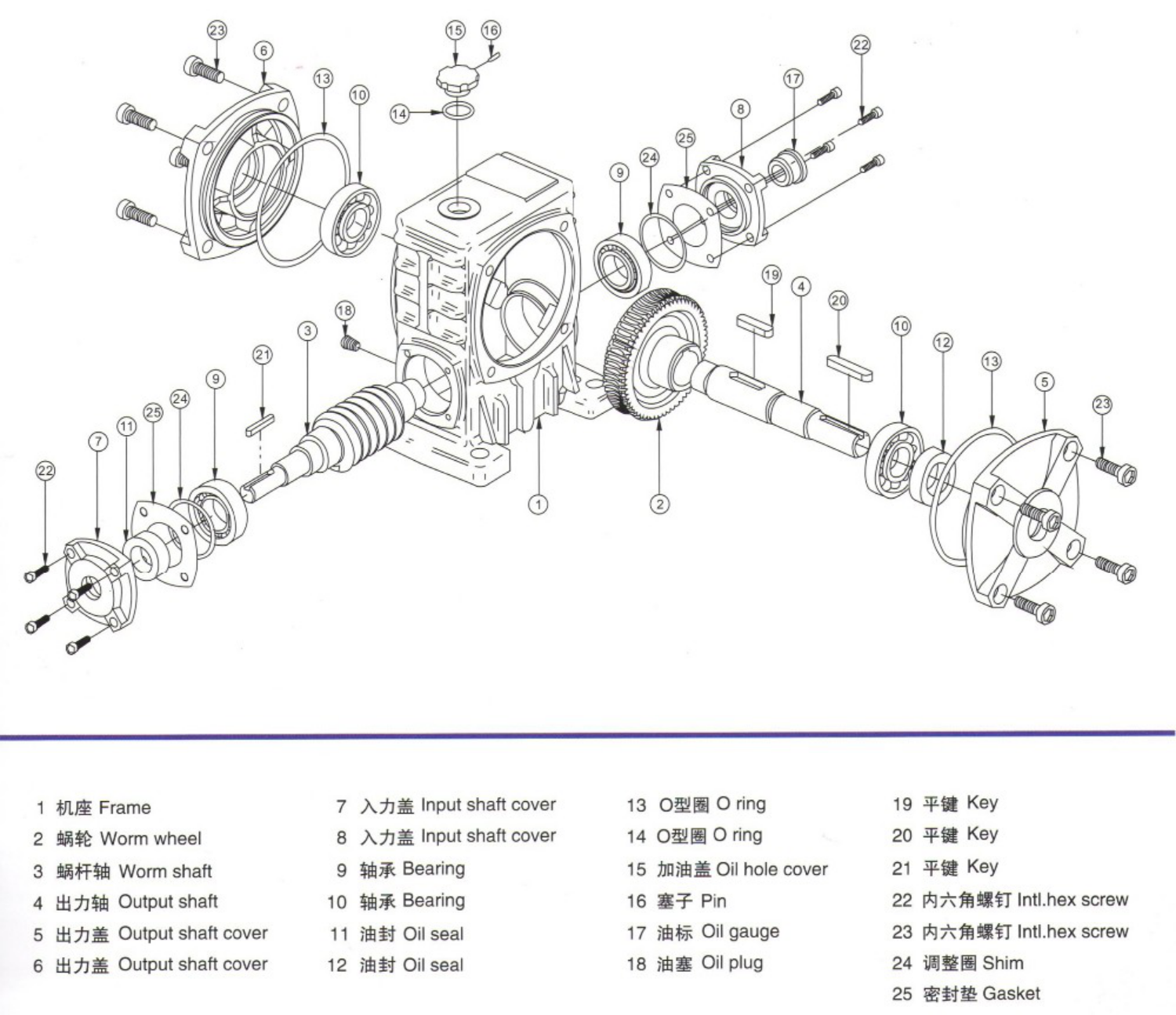

Product Description

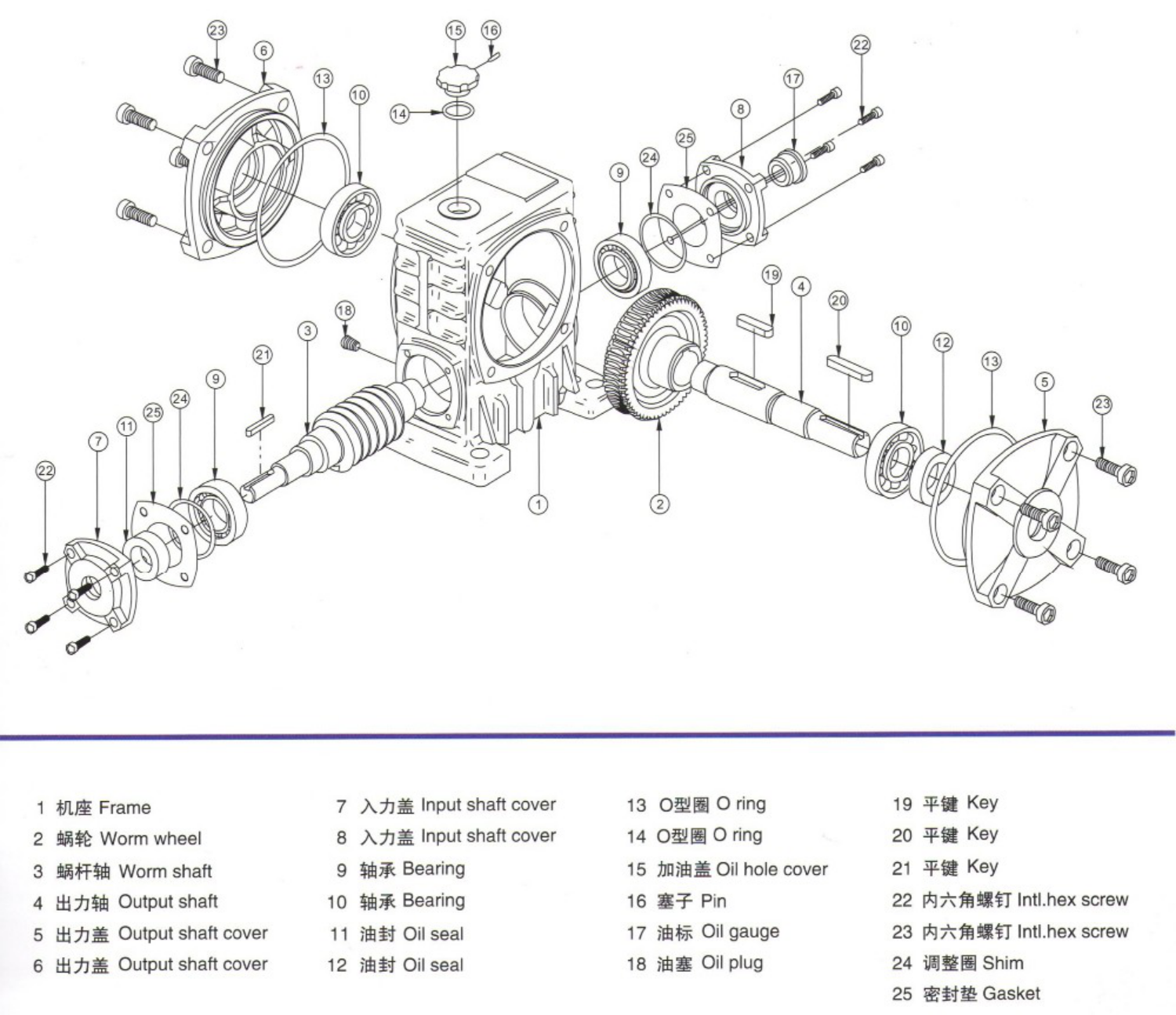

Product Description

Internal Gear Processing

Internal Gear Ring drawing CHECK, Make Forging Mold, Forging Mold Quality Inspection Check, Machine Processing, Check Size\Hardness\Surface Finish and other technical parameters on drawing.

Inner Gear Package

Spray anti-rust oil on large internal girth Gear, Wrap waterproof cloth around , Prepare package by shaft shape & weight to choose steel frame, steel support or wooden box etc.

OEM Customized Large Inner Gear Ring

We supply OEM SERVICE, customized internal helical gear with big module, more than 1tons big weight, more than 3m length, 42CrMo/35CrMo or your specified required material inner gear ring.

Detailed Photos

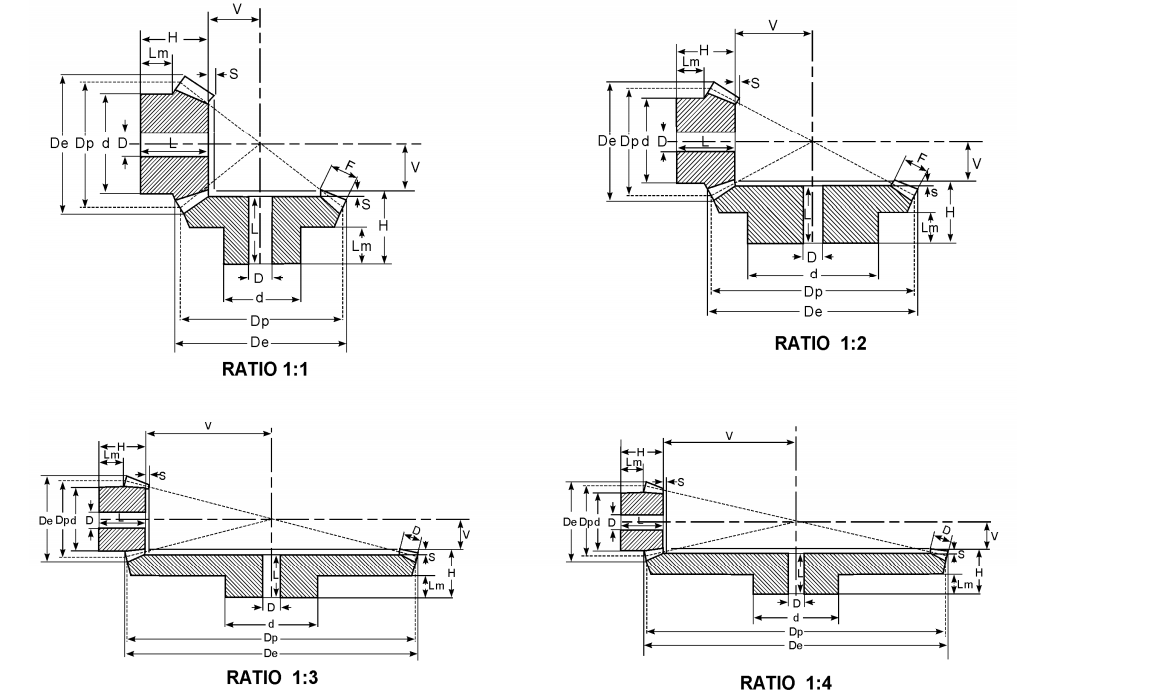

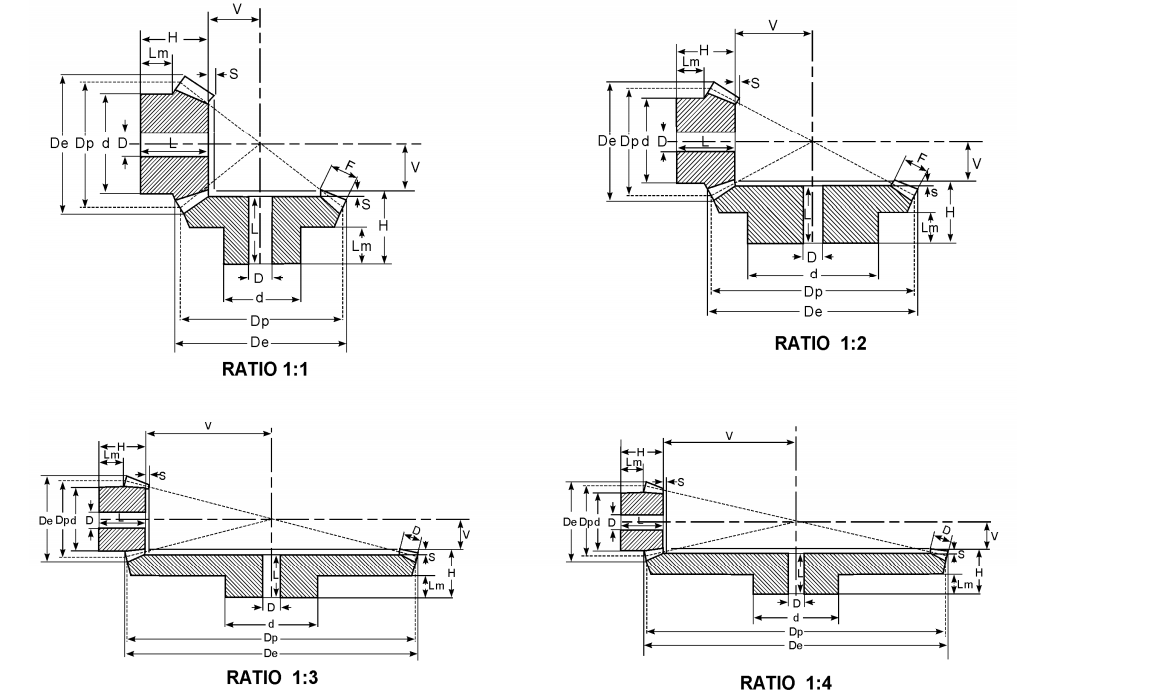

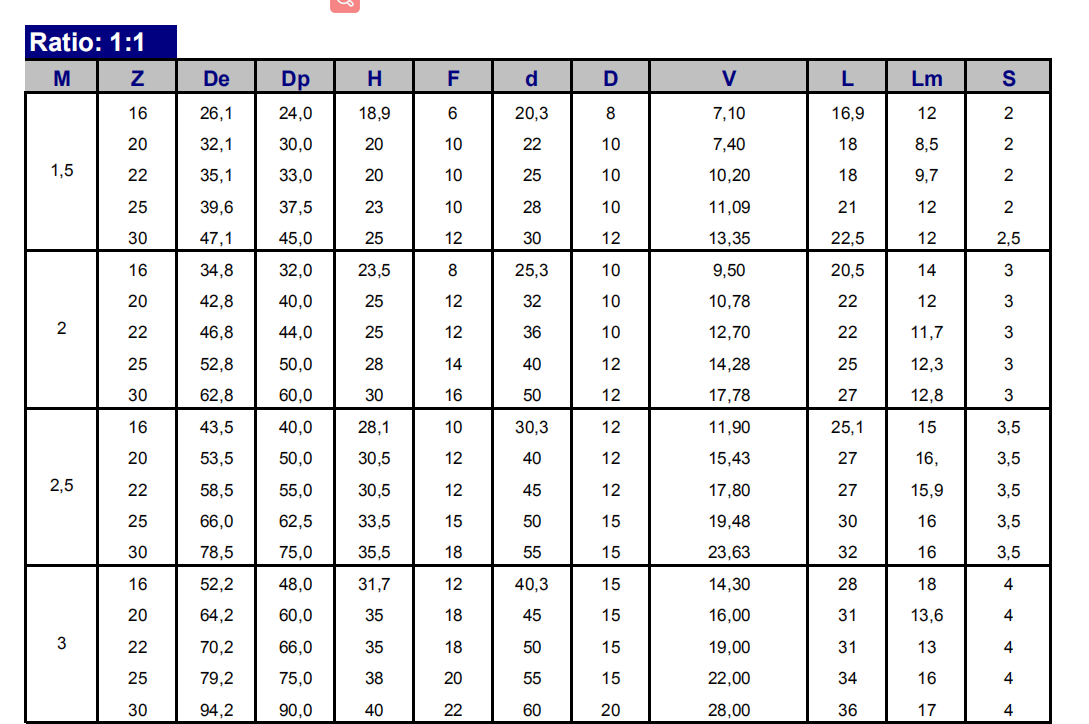

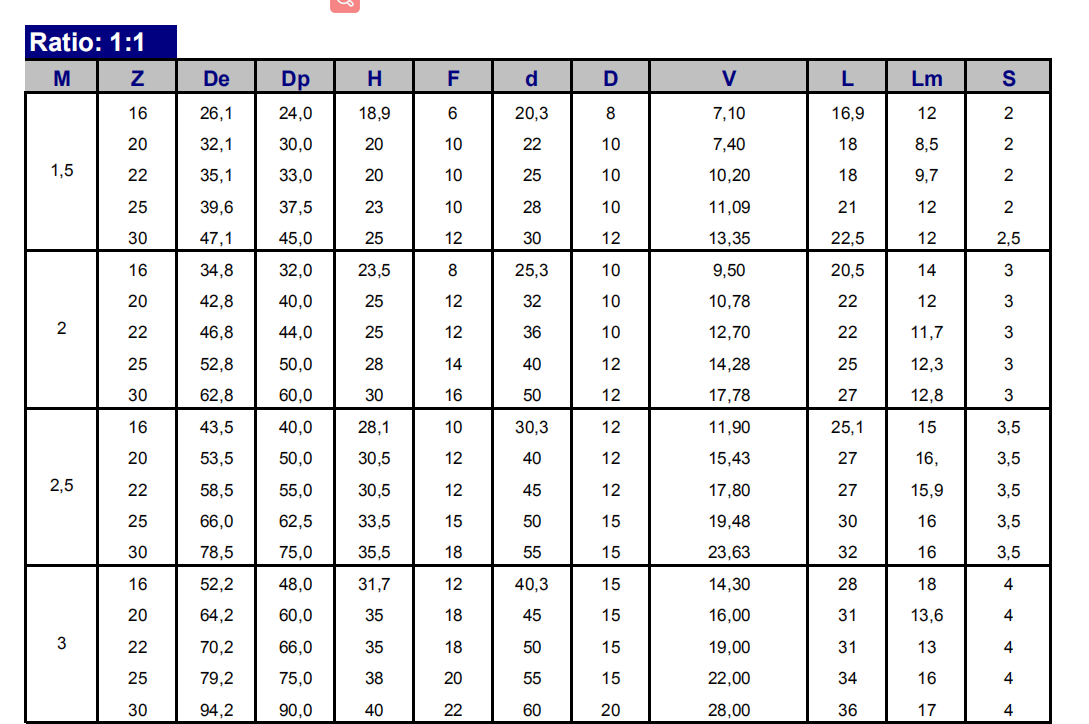

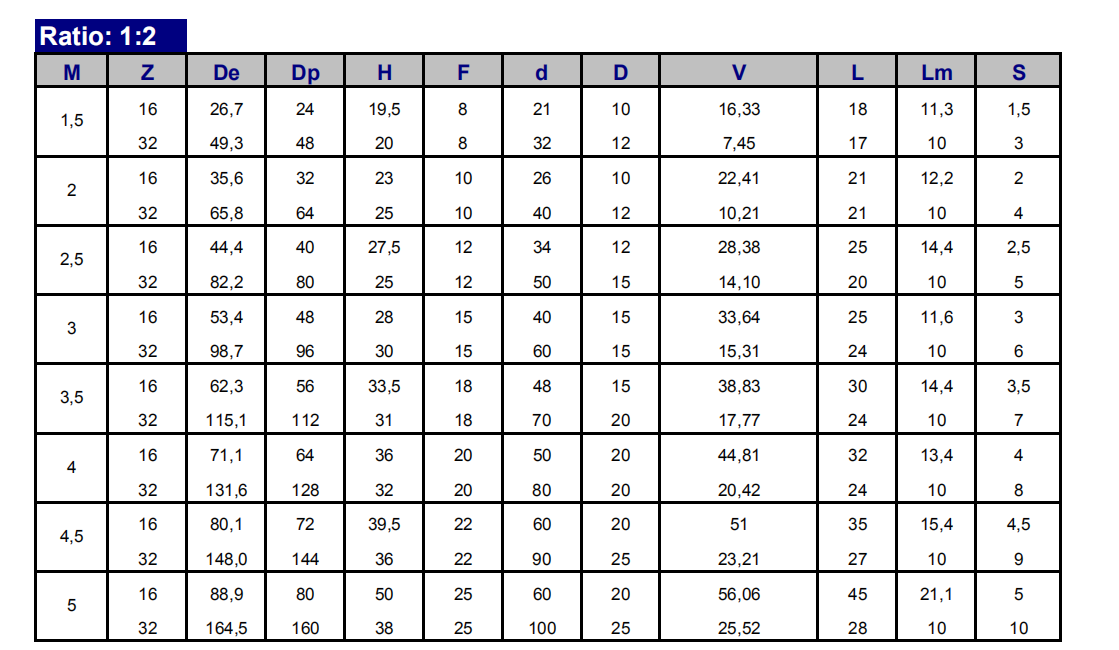

Product Parameters

| Module | m | Range: 5~70 |

| Gear Teeth Number | z | OEM/Customized |

| Teeth Height | H | OEM/Customized |

| Teeth Thickness | S | OEM/Customized |

| Tooth pitch | P | OEM/Customized |

| Tooth addendum | Ha | OEM/Customized |

| Tooth dedendum | Hf | OEM/Customized |

| Working height | h’ | OEM/Customized |

| Bottom clearance | C | OEM/Customized |

| Pressure Angle | α | OEM/Customized |

| Helix Angle, | OEM/Customized | |

| Surface hardness | HRC | Range: HRC 50~HRC63(Quenching) |

| Hardness: | HB | Range: HB150~HB280; Hardening Tempering/ Hardened Tooth Surface |

| Surface finish | Range: Ra1.6~Ra3.2 | |

| Tooth surface roughness | Ra | Range: ≥0.4 |

| Gear Accuracy Grade | Grade Range: 5-6-7-8-9 (ISO 1328) | |

| Diameter | d | Range: >1m |

| Weight | Kg | Range: >100kg/ Single Piece |

| Toothed Portion Shape | internal, inner gear ring | |

| Material | Casting 42CrMo/45# steel or Customized | |

| Gear Teeth Milling | √ | |

| Gear Teeth Grinding | √ | |

| Heat Treatment | Quenching /Carburizing | |

| Sand Blasting | Null | |

| Testing | UT\MT | |

| Trademark | TOTEM/OEM | |

| Application | Gearbox, Reducer etc | |

| Transport Package | Export package (steel frame, wooden box, etc.) | |

| Origin | China | |

| HS Code | 8483409000 |

CHINAMFG SERVICE

TOTEM Machinery all the time works to supply GEAR SHAFT, ECCENTRIC SHAFT, HERRINGBONE GEAR, BEVEL GEAR, INTERNAL GEAR and other parts for transmission device & equipment (large industrial reducer & driver). Which mainly use to industrial equipment on fields of port facilities, cement, mining, metallurgical industry etc.

TOTEM Machinery invests and becomes shareholders of several machine processing factories, forging factories, casting factories, relies on these strong reliable and high-quality suppliers’ network, to let customers worry-free purchase.

TOTEM Philosophy: Quality-No.1, Integrity- No.1, Service- No.1

24hrs Salesman on-line, guarantee quick and positive feedback. Experienced and Professional Forwarder Guarantee Log. transportation.

About CHINAMFG

1. Workshop & Processing Strength

2. Testing Facilities

3. Customer Inspection & Shipping

Contact CHINAMFG

ZheJiang CHINAMFG Machinery Co.,Ltd

Facebook: ZheJiang Totem

FAQ

What’s CHINAMFG product processing progress?

Drawing CHECK, Make Forging Mold, Forging Mold Quality Inspection Check, Machine Processing, Check Size\Hardness\Surface Finish and other technical parameters on drawing.

How about TOTEM’s export package?

Spray anti-rust oil on Herringbone Gear Shaft, Wrap waterproof cloth around Gear Shaft for reducer, Prepare package by shaft shape&weight to choose steel frame, steel support or wooden box etc.

Could I customize gear\gear shaft on TOTEM?

We supply customized Gear Shaft,Eccentric Shaft,Herringbone Gear,Internal Gear,Bevel Gear with big module, more than 1tons big weight, more than 3m length, forging or casting 42CrMo/35CrMo or your specified required material.

Why can I choose TOTEM?

TOTEM has 24hrs Salesman on-line, guarantee quick and positive feedback.

TOTEM Machinery invests and becomes shareholders of several machine processing factories, forging factories, casting factories, relies on these strong reliable and high-quality supplier’s network, to let customers worry-free purchase.

Experienced and Professional Forwarder Guarantee Log. transportation.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Applications of Helical Couplings in Various Industries

Helical couplings find wide use in numerous industries and applications due to their versatility, reliability, and ability to handle misalignment and transmit torque:

- Manufacturing: Helical couplings are used in CNC machines, mills, lathes, and other manufacturing equipment to ensure precise power transmission and minimize vibration.

- Robotics: Robotic arms and joints often employ helical couplings to connect motors and actuators, allowing for flexibility while maintaining accurate motion control.

- Medical Equipment: Imaging devices, surgical robots, and medical equipment often use helical couplings to ensure precise movement and positioning.

- Aerospace: Helical couplings are used in aerospace applications such as satellite systems, UAVs, and aircraft systems where lightweight yet durable coupling solutions are required.

- Automotive: Helical couplings find use in automotive testing equipment, vehicle assembly lines, and robotics for manufacturing and testing automotive components.

- Packaging and Conveyors: Packaging machinery, material handling systems, and conveyors utilize helical couplings to ensure efficient and accurate movement of products.

- Printing: Printers and labeling machines benefit from helical couplings’ ability to handle misalignment and transmit motion accurately.

The broad range of applications highlights the adaptability and reliability of helical couplings across various industries.

Utilization of Helical Couplings in Mechanical Systems

A helical coupling, also known as a beam coupling, is a type of flexible coupling that is used in mechanical systems to transmit torque and motion between shafts while accommodating misalignment. Here’s how it is utilized:

Helical couplings consist of two hubs, each with helical slots that interlock with the other hub’s slots. The interlocking design allows for flexibility in multiple directions while maintaining torsional rigidity.

When utilized in mechanical systems:

- Misalignment Compensation: Helical couplings can handle angular, axial, and parallel misalignments between shafts. The helical slots provide flexibility, allowing for small amounts of misalignment without transmitting excessive stress to connected components.

- Torque Transmission: Helical couplings transmit torque from one shaft to another while minimizing backlash. The helical slot design distributes torque evenly across the coupling’s surface, ensuring efficient power transmission.

- Reduced Vibration: The helical design of the coupling helps absorb shocks and vibrations, contributing to smoother operation and reduced wear on connected components.

- Compact Design: Helical couplings have a compact and lightweight design, making them suitable for applications with limited space.

- Simple Installation: These couplings are relatively easy to install, with minimal maintenance requirements.

- Various Applications: Helical couplings are commonly used in robotics, motion control systems, CNC machines, and other applications where precision and flexibility are essential.

In summary, helical couplings provide an effective solution for transmitting torque and motion between shafts while accommodating misalignment and reducing vibrations in various mechanical systems.

Diagnosing and Addressing Issues with Helical Couplings in Machinery Systems

Diagnosing and addressing issues related to helical couplings in machinery systems require a systematic approach:

- Visual Inspection: Regularly inspect the coupling for signs of wear, misalignment, or damage, such as cracks, corrosion, or deformation.

- Noise and Vibration: Unusual noise or increased vibration can indicate coupling problems. Use vibration analysis tools to identify issues and their severity.

- Power Transmission Issues: If you notice a decrease in power transmission efficiency or sudden changes in torque, it may be due to coupling problems.

- Temperature Changes: Abnormal temperature increases in the coupling area could indicate friction or misalignment issues.

- Lubrication: Check the lubrication of the coupling regularly. Insufficient or contaminated lubricant can lead to increased wear and poor performance.

- Alignment: Ensure that the coupling is properly aligned. Misalignment can cause premature wear and reduce the coupling’s lifespan.

- Fasteners: Examine fasteners like set screws or clamping elements. Loose or damaged fasteners can affect coupling performance.

- Replace Damaged Parts: If you identify worn or damaged parts, replace them promptly with genuine replacement components.

- Balancing: Imbalance can lead to vibration and wear. Balance the coupling if necessary.

- Proper Installation: If the coupling was recently installed, ensure it was installed correctly and according to the manufacturer’s guidelines.

- Consult Experts: If you’re unsure about diagnosing or addressing issues, consult with experts or engineers who specialize in coupling systems.

By conducting regular inspections, monitoring performance, and addressing issues promptly, you can maintain the optimal functioning of helical couplings in your machinery systems.

editor by CX 2024-03-14

China best CNC Turning Pure White Gear Coupling / Linear Threaded Boot

Product Description

CNC Turning Pure White Gear Coupling / Linear Threaded Boot

Products Type

We can custom shape,size,color material and quantity for plastic gear coupling as your requirment.

Products Specification

1. Various hardness for your choice.

2. Good abrasion, heat and oil resistance.

3. Good anti-aging performance and gas tightness.

4. Ease of bonding to other material.

5. Excellent oxygen and CHINAMFG resistance.

6. Non-flammable,self-extinguish.

| Material | PA,PA6,PA66,PP,PE,LDPE,HDPE,UWHDPE,PTFE,POM,ABS,or Custom Compound (Any custom compound plastic is available) |

| Size | According to samples or drawings |

| Color | Black,white,red,green,transparent or any color according to Pantone colors |

| Finish | High Gloss,Fine Grain,Electroplating,Painting,Printing,Texture etc,or as request |

| Type | Round,square,rectangular,or any nonstandard shape as request |

| Logo | Debossed,embossed,printed logo or as request |

Plastic Material Properties

Company Profile

Zhongde (ZheJiang ) Machinery Equipment Co.,LTD is a company integrated in design,OEM&ODM plastic&rubber&CNCparts production.We can provide the best products and service at a competitive price.

Main Products

We can provide OEM service,which means producing base on your drawings or samples,also we can design according to its application or customer`s requirments.

Order Operation Flow

We execute each step according to the operation process flow, strictly, seriously and meet the requirements of customers with good quality on time.

For Fast Quotation,Please Inform Below Details

1. Production type

2. Material specification (or let us know the using environmental)

3. Size details? (or provide drawings or samples for refference)

4. Quantity request

5. Prefer color

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Comparison of Helical Couplings with Beam Couplings and Oldham Couplings

Helical couplings, beam couplings, and Oldham couplings are all flexible coupling types used in mechanical systems, but they differ in design and characteristics:

- Helical Couplings: Helical couplings offer high torque transmission, axial flexibility, and some angular misalignment compensation. They are known for their helical-cut grooves that provide flexibility and compensate for misalignment, making them suitable for applications with moderate misalignment.

- Beam Couplings: Beam couplings consist of one or more flexible beams that provide radial flexibility and angular misalignment compensation. They excel in applications requiring high precision and low torque. However, they have limitations in transmitting high torque and axial misalignment.

- Oldham Couplings: Oldham couplings use two hubs and a center disc to transmit torque while accommodating angular misalignment. They offer higher torsional stiffness compared to helical and beam couplings. Oldham couplings are suitable for applications with moderate torque transmission and angular misalignment.

When comparing these coupling types:

- Helical couplings are preferred for applications with moderate torque, axial flexibility, and moderate angular misalignment.

- Beam couplings are chosen for applications requiring precision motion, low torque, and minimal angular misalignment.

- Oldham couplings are used when higher torsional stiffness and moderate angular misalignment compensation are needed.

The choice depends on factors such as torque requirements, misalignment, precision, and the specific needs of the application. Each coupling type offers unique benefits and limitations, allowing engineers to select the most suitable coupling for their machinery systems.

Correct Installation and Maintenance of Helical Couplings in Machinery

Proper installation and maintenance are essential for the optimal performance and longevity of helical couplings:

Installation:

- Alignment: Ensure that the shafts to be connected are properly aligned within the specified tolerances. Misalignment can lead to premature wear and reduced coupling life.

- Coupling Insertion: Gently slide the coupling onto the shafts, ensuring that it is fully seated. Avoid forcing the coupling onto the shafts to prevent damage.

- Tightening: Follow the manufacturer’s guidelines for tightening the coupling fasteners. Use the recommended torque values to prevent overtightening or undertightening.

- Lubrication: Apply the appropriate lubricant to any contacting surfaces of the coupling, following the manufacturer’s recommendations.

- Secure Fasteners: Double-check that all fasteners are properly secured. Ensure that any set screws or locking mechanisms are correctly positioned and tightened.

Maintenance:

- Regular Inspection: Periodically inspect the coupling for signs of wear, damage, or misalignment. Address any issues promptly to prevent further problems.

- Lubrication: Maintain proper lubrication as recommended by the manufacturer. Lubrication helps reduce friction, wear, and heat buildup.

- Environmental Conditions: Consider the operating environment of the coupling. If the machinery is exposed to harsh conditions, take measures to protect the coupling from contaminants and corrosive substances.

- Load Changes: If the operating conditions change, such as increased loads or speeds, reevaluate the coupling’s suitability for the application and adjust maintenance intervals accordingly.

- Replacement: Over time, couplings may wear out due to normal usage. If wear is significant or if the coupling shows signs of failure, replace it with a new one to ensure safe and reliable operation.

By following proper installation and maintenance practices, you can maximize the performance and lifespan of helical couplings in your machinery systems.

Diagnosing and Addressing Issues with Helical Couplings in Machinery Systems

Diagnosing and addressing issues related to helical couplings in machinery systems require a systematic approach:

- Visual Inspection: Regularly inspect the coupling for signs of wear, misalignment, or damage, such as cracks, corrosion, or deformation.

- Noise and Vibration: Unusual noise or increased vibration can indicate coupling problems. Use vibration analysis tools to identify issues and their severity.

- Power Transmission Issues: If you notice a decrease in power transmission efficiency or sudden changes in torque, it may be due to coupling problems.

- Temperature Changes: Abnormal temperature increases in the coupling area could indicate friction or misalignment issues.

- Lubrication: Check the lubrication of the coupling regularly. Insufficient or contaminated lubricant can lead to increased wear and poor performance.

- Alignment: Ensure that the coupling is properly aligned. Misalignment can cause premature wear and reduce the coupling’s lifespan.

- Fasteners: Examine fasteners like set screws or clamping elements. Loose or damaged fasteners can affect coupling performance.

- Replace Damaged Parts: If you identify worn or damaged parts, replace them promptly with genuine replacement components.

- Balancing: Imbalance can lead to vibration and wear. Balance the coupling if necessary.

- Proper Installation: If the coupling was recently installed, ensure it was installed correctly and according to the manufacturer’s guidelines.

- Consult Experts: If you’re unsure about diagnosing or addressing issues, consult with experts or engineers who specialize in coupling systems.

By conducting regular inspections, monitoring performance, and addressing issues promptly, you can maintain the optimal functioning of helical couplings in your machinery systems.

editor by CX 2024-03-06

China manufacturer & factory supplier for EPT in Santa Cruz Bolivia R Series Helical Gear Parallel Shaft Speed Reducer With high quality best price & service

ISO 9001:2000 & AS 9100B qualified custom made manufacturer of roller chains. Specifications of roller chains consist of .1475 in. to .3750 in. pitch, 5.9 in. to 35.4 in. length, 180 lbs. to 1529 lbs. tensile load ability & .035 lbs. to .276 lbs. fat/ft. We are aiming to satisfy the demands of the customers close to the planet.. a specialized provider of a complete assortment of chains, sprockets, gears, gear racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….

Overview

Swift Specifics

- Relevant Industries:

-

Building Materials Stores, Manufacturing Plant, Equipment Mend Retailers

- Gearing Arrangement:

-

Helical

- Output Torque:

-

Max. 50000N.m

- Input Velocity:

-

1440rpm

- Output Pace:

-

eight-300rpm

- Location of Origin:Zhejiang, China

- Model Name:

-

OEM

- Model Number:

-

FR

- Rated Electrical power:

-

.twelve-200KW

- Product Name:

-

R Sequence Helical Gear Parallel Shaft Pace Reducer

- Mounting Situation:

-

As Essential

- Warranty:

-

12 Months

- Certificate:

-

CE ISO9001

Supply Potential

- Offer Capacity:

- 200000 Piece/Parts per Calendar year

Packaging & Supply

“EPG” manufacturer rotocultivator ploughshares in T.S. complete lines developed in our manufacturing facility have been tested and appraised by the Ministry of Agriculture and have received the license of popularizing farm equipment promulgated by the Ministry of Agriculture of the People’s Republic Worm gears are typically created by hobbing with a hob or cutting tool extremely related to the worm that the gear mates with. The worm might be turned, hobbed, milled, or floor.of China.

- Packaging Details

- Normal export packing and wood pallet packing

- Port

- SHANGHAI or NINGBO Port

Online Customization

We get a good deal of queries bordering PTO shafts and how to connect them to your tractor. In today’s post, we’ll protect the principles of PTO, PTO Shafts, and PTO adapters for your tractor mounted implements. PTO stands for “Power Take-Off” and is the main system for offering energy to an attachment or employ (these kinds of as a flail mower) by way of PTO shaft.By supplying rotational strength by way of the driveshaft (or cardan shaft) a range of tractor mounted implements can be operated by little and mid-sized tractors.

Exceptional Attributes of R Collection Helical Gear Parallel Shaft Pace Reducer

– F Sequence Decelerator is characterised by compact construction, mild bodyweight, large torque and excellent overall performance

– It is created of rib-bolstered rigid situation and quality alloy-metal gear which is hardened by carbon penetration and grinned specifically

– Secure in running, low sound, massive in load, lower in consumption, productive in transmission, reduced in temperature rise, and lengthy in service existence

– The mounting designs are footing, flange, torque arm and so on. The output design are shaft, hollow shaft, the alpine and shrink disc are for selection.

Images of R Collection Helical Equipment Parallel Shaft Velocity Reducer

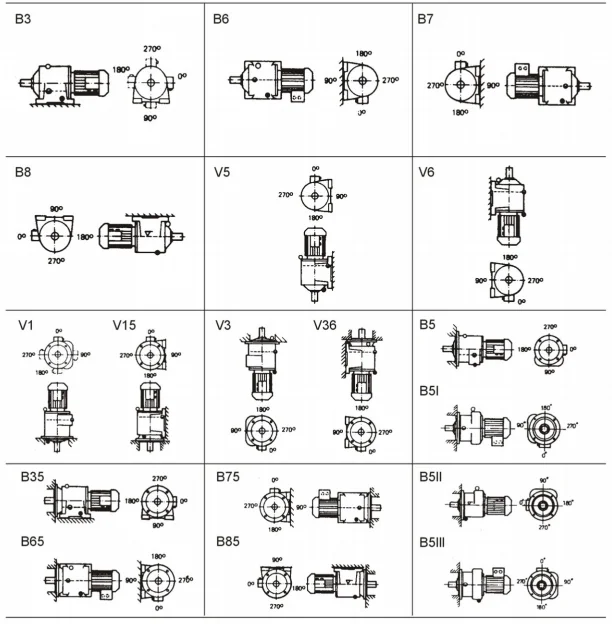

Different Mounting Postion of R Collection Helical Gear Parallel Shaft Velocity Reducer

Packing Images of R Series Helical Equipment Parallel Shaft Pace Reducer

Internal Packing: PP bag with carton

Outer Packing: Wood scenario

Shipment: fourteen-20 days on obtaining the deposit.

We can make four hundred,000 units of worm gearboxes, 100,000 units of gear reducers, 50,000 units of other speed reducers, one hundred fifty,000 models of flexible couplings, and a hundred,000 units of pace-reducer equipment every single year.

70% of our products have been exported to 40 much more international locations, and our buyers appear from Italy, Germany, Usa, Canada, Spain, United kingdom, India, Mexico, Brazil, Argentina, Turkey, Singapore and other major industrial countries. 30% of them are OEM made for direct producers of other items.

Q1. Is your high quality excellent?

A1: High quality in no way explain to lies, we are the largest maker and exporter of worm gear reducer in Asia, the very first reducers and gearboxes maker in China, who has been given license since 1993. Also, we experienced accomplished ISO9001 and CE Certificate amongst all companies.

Q2. How is your price? Can you provide any price reduction?

A2: We will give the best cost we can base on your wants and the quantities.

Q3. Do you offer you any visiting?

A3: Yes! We sincerely invite you to pay a visit to us! We can select you from airport, railway station and so on. Also, we can arrange housing for you. Remember to let us know in advanced.

This fall. When is the best time to make contact with you?

A4: You can speak to us by e-mail any time, we will reply you ASAP. If you want speak to by cellphone, our operating hour is Mon-Sat 9am-seventeen:30pm.

At any time_power Group

Tackle: No.789-B8Shenhua Road, XiHu Dsitriction Enco&Tech Advancement Zone HangZhou Town, ZJ, P.R.

Tel: 0086-571-88220971/Mob: +86 13083988828

WhatsApp/Skype: +86 13083988828

Internet site: www.hzpt.com

China manufacturer & factory supplier for factory in Bur Sa’id Egypt manufacturer for high quality metal steel spur gear pinions and double spur gear machining parts spur gear With high quality best price & service

ISO 9001:2000 licensed. Stocking distributor of electricity transmission merchandise including roller & several strand roller chains. Items also consist of brakes, push components, gears, torque limiters, U-joints, pulleys, sheaves, encoders, belt drives, clutches & motors are also available.Hangzhou EPG Co.,Ltd. , was founded in November, 1997. With its five wholly owned subsidiaries.

Overview

Rapid Details

- Applicable Industries:

-

Manufacturing Plant

- Nearby Services Location:

-

None

- Application:

-

Mechanical Tools

- Surface area remedy:

-

Polishing

- Processing:

-

Turning

- Tolerance:

-

Customer’s Drawing Request

- Heat treatment method:

-

Substantial Frequency Induction Hardening

- Certification:

-

Underneath the guidance of managerial perception of “Serving agriculture, scoring a achievement via high quality of merchandise and honesty in organization”, our merchandise have been trustworthy by clients and have gained a larger share of market.

ISO9001:2009/TS 16949

- Services:

-

24 Several hours On the web

Supply Ability

- Source Capacity:

- 5000 Piece/Items per Thirty day period

Packaging & Delivery

- Packaging Details

- Neutral paper packaging,wooden boxes for outer box or according to buyer desire

- Port

- shanghai Port/Ningbo Port

-

Guide Time

: -

Amount(Parts) 1 – a thousand >1000 Est. Time(days) fifteen To be negotiated

On the internet Customization

We Ever-Electricity Group with 4 branches above 1200 employees is one of the most significant transmission components and machining items companies in China

Product Description:

We specialized in producing auto gears , bike gears, gearbox, special vehicle (power takeoff, snowmobiles, engineering vehicles) gears, generator accessories, stainless metal ice crusher etCast Iron Gearbox: Soon after Portray with Red Antirust Paint, Paint with the Colour of RAL 5010 Gentian Blue Models: Hollow Shaft Enter with IEC-normalized Motor Flange c.

|

Material |

1020,1045,20CrMnTi, and so on. |

|

Machining Method |

Gear Hobbing , Equipment Shaping, Gear Shaving, Gear Grinding |

|

Modules |

1., 1.twenty five, 1.5, 1.seventy five, 2., 2.25, 2.5….8. and many others. |

|

Heat Remedy |

Carburizing & Quenching, Carbonitriding |

|

Normal |

DIN, ISO/GB EPG Team PTO shafts can be employed for speeds up to a thousand rpm. The greatest functioning duration of the PTO shafts varies in accordance to the measurement of the tubes The assortment of the PTO shafts of RPG Team contains 4 series , in accordance to the tube condition, AGMA, JIS,ISO/TS16949:2009 |

China manufacturer & factory supplier for Hot in Minsk Belarus internal gear crossed roller slewing Ring bearing four point contact ball slewing bearing 07-1304-04 For tower crane With high quality best price & service

As a outcome, we have grow to be a extensive maker in the motion and control discipline supplying an extensive lineup of items with outstanding sturdiness, atmosphere-friendliness, and high quality.Our products are used in several fields.

Overview

Swift Details

- Relevant Industries:

-

Constructing Substance Shops, Manufacturing Plant, Farms

- Brand Title:

-

OEM

- Brand name:

-

syf

- Bore measurement:

-

two hundred-1300 mm

- Exterior Diameter:

-

three hundred-8000mm

- Content:

-

50Mn/42CrMo/Customized

- Module:

-

10

- Tooth:

-

syf

- Dimension:

-

1143*1431*ninety seven mm

- Excess weight:

-

323 KG

Supply Ability

- Provide Capacity:

- 1500 Set/Sets for every Thirty day period

Packaging & Shipping and delivery

- Packaging Specifics

- 1. Bearing surface area is covered with the anti-rust oil 1st And then wrapped with the plastic film

2. And then packed with Kraft paper and skilled belts

three. At previous, with picket box totally at the outer packing to in void the rust or the moist

4. Packaging can be done according to customer’s needs.”>HGB Packaging Particulars:

1. Bearing surface area is lined with the anti-rust oil very first And then wrapped with the plastic movie

two. And then packed with Kraft paper and skilled belts

three. At last, with wood box totally at the outer packing to in void the rust or the moist

four. Packaging can be accomplished according to customer’s needs.

- Port

- China any Port

-

Direct Time

: -

Amount(Luggage) one – a hundred >100 Est. Time(times) 7 To be negotiated

On the internet Customization

Why Choose Us

Item Description

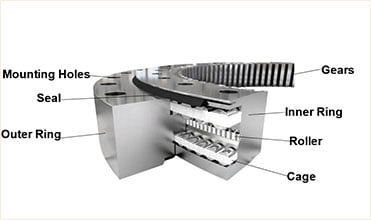

one,Solitary row 4 stage speak to ball slewing bearing

2,One row cross roller slewing bearing

3,Double-row ball slewing bearing

four,3-row roller slewing bearing

five,Roller/Ball Combination Slewing bearing.

Single row 4 point

make contact with ball slewing bearing

Single row cross

roller slewing bearing

Double Row

Ball slewing bearing

A few row

roller slewing bearing

Roller/Ball Combination

Slewing bearing

|

Sort |

Solitary row 4 stage get in touch with ball slewing bearing |

|

Rollng factors |

Metal ball / Cylinder Roller |

|

Rollng aspects Materials |

GCr5/GCr15SiMn/Tailored |

|

Bearing Materials |

50Mn/42CrMo/42CrMo4V /Custom-made |

|

Cage Material |

Nylon/ steel /copper |

|

Composition |

taper pin , Mounting holes,Interior ring ,grease fitting,load plug, seals , roller ,spacer balls or separators |

|

Outer diameter |

50-10000mm |

|

Bore dimension |

50-10000mm |

|

Mounting hole |

Through gap/Tapped hole |

|

Raceway hardness |

55-62HRC |

|

Internal and outer ring modulation hardness |

229-269HB/Custom-made |

|

Equipment variety |

No gear ,Inner equipment , External gear. |

|

Embellish grease |

EP2 lithium lubricating grease |

|

Certificate |

Stomach muscles.BV,DNV,ISO9001,GL |

|

Application area |

Ladle turret,Stacker crane,Bucket wheel equipment,Solar heliostat Tracking Program,port crane, Cabling machine,tower crane , offshore system,ferris wheel, Palletizing robot,Rotary metallurgical furnace,can packing equipment,Wind blade transporter,shield tunneling equipment,tube thrust bench,excavator |

|

Manufacturer Name |

HGB |

|

Spot of Origin |

HangZhou Henan |

|

Guarantee |

12 months |

|

Payment expression |

T/T is our 1st option |

|

Packing details |

1,Filling with anti-rust oil two.Corved with Plastic paper 3.Corved with kraft paper four.Corved with Blue tie five.Put in wooden box |

Item Details

|

Excavator Slewing Bearings are extensively employed for all manufacturers of excavators, suit for follows types |

|||

|

Slewing Bearings For Hita chi |

EX40-1 EX60-1-2-3-5 EX70-5 EX90 EX100-1-2-3-5 EX110-5 EX120-1-2-3-5 EX130-5 EX200-1-2-3-5 EX210-5 EX220-5 EX270 EX300-1-2-3-5 EX-330 EX330-3 EX350-5 EX400-3 EX400-5 EX470-3 EX870 ZAX60 ZX55-R ZAX70 ZAX80 ZAX110 ZAX120 ZAX130 ZAX200-3-6 ZAX210 ZAX220-5 ZAX230 ZAX240 ZAX240-3 ZAX250-3 ZAX270-3 ZAX450-1 ZAX450-3 ZAX450-5 ZAX750 UH063 UH07-7 UH083 |

||

|

Slewing Bearings For E |

E45 E60 E70B E80 E110 E120B E305 E311 E312B/C E307B/C/D E308 E315 E200 E200B E320 E320B E320C E320D E320L E324D E325/B/C/D E330/B/C E345/B E350 E365 E380 E385 |

||

|

Slewing Bearings For Laptop |

PC30 PC30-2 PC35 PC40 PC45 PC50 PC50-7 PC55 PC60-5-6-7 PC70 PC75 PC78 PC100-3-5 PC120-3-5-6-6E PC128 PC130-7 PC150-5-7 PC160-7 PC200-1-2-3-4-5-6-7-8 PC210-7 PC220-3-5-6 PC240-8 PC227 PC228 PC270-7 PC300-1-2-3-4-5-6-7 PC350-6-7 PC360-6-7 PC400-3-5-6-7-8 PC450-5-6 PC460-7 PC600-6 PC650-3 PC650 PC800 PC1000 PC1200 PC1250 |

||

|

Slewing Bearings For Sumitomo |

SH50 SH60-1 SH120-1-2/A1/A2/A3/Z3/C3 SH120C3 SH260 SH200 A1/A2/A3/C2/C3/Z3 SH210-5 SH210-A5 SH220-3 SH225 SH240-3-5 SH280 SH350 |

||

|

Slewing Bearings For Hyundai |

R55-5-7 R60-5-7 R70-7 R80-7 R110-7 R130-5-7 R130LC-3-5 R150-7 R170-5 R200-3-5-7 R205-7 R210 R215-7 R220-5-7-9 R225LC-7 R260-7 R280 R290-7 R290LC-3 R290LC-7 R300LC R305LC-7 R320 R330LC R335-7 R375 R360LC-7 R450-7 R450LC R962 |

||

|

Slewing Bearings For Kato |

DH35 DH55 DH60 DH80-7 DH150-5-7 DH200 DH215-7 DH220-2-3-5-7-9 DH258-7 DH280-5 DX60 DX200 DX225 DX260 DX300 DH280 DH290-5 DH300LC-7 DH340 |

||

|

Slewing Bearings For Kobelco |

SK60-3-5 SK100 SK120-1-2-3-5 SK130-8 SK140-8 SK200-6 SK210-6 SK200-6E SK07 SK200-3-5-8 SK210-8 SK220 SK230-6 SK235 SK250-6-8 SK260-8 SK330-6 SK350-8 SK480-eight |

||

|

Slewing Bearings For LIUGONG & For XCMG |

CLG906 CLG907 CLG908 CLG915 CLG915D CLG205C CLG225C CLG220LC CLG225 CLG200 CLG200-3 CLG920D CLG922D CLG925D CLG936LC CLG936D XE60 XE210 XE215 XE150A/B XE230 XE370 210-8 220-8 |

||

|

Slewing Bearings For SANY |

SY65 SY75 SY135 SY185 SY195 SY200 SY205 SY210 SY215-7-8-9 SY235 SY300 SY305 SY310 SY335 SY360 SY365 SY420 |

||

|

Slewing Bearings For Volov |

EC55 EC210 EC210B EC240 EC290 EC360 |

||

|

Slewing Bearings For Liebherr |

R914 R916 R924 R944 |

||

|

Slewing Bearings For Yuchai |

YC15 YC20 YC35 YC60 YC6-5T YC85 YC210-8 YC230-8 YC350 YC400-8 |

||

|

Slewing Bearings For XGMA and For LONKIN |

XG60 XG808 XG815 XG820 XG822 XG823 XG825 LG6060 LG6075 LG6085 LG6090 LG6210 LG6230 LG6225 LG6235 |

||

|

Slewing Bearings For Atlas and For Sunward |

for Atlas3306LC 2006 TC360 2306 SWE50 SWE60 SWE70 SWE80 SWE90 SWE150 |

||

|

A lot more Versions for |

For LovolFR85 FR150 FR210 For Bobcat80 For SW210 SW230 For Takeuchi135 one hundred seventy five For Circumstance CX210B For JCM906D JCM921 JCM922 For EPG75 161 For ZY80 ZY210 For JCB8056 JCB220 For ZW60 ZE80 JV60 SC360 HL60 |

||

Bearing Elements

Metal ball/Roller:carbon-chromium bearing steel GCr15SiMn or GCr15 for rolling Substance

Cage: incorporate integral cage, section cage and spacer-variety cage. twenty# metal or copper for integral and phase cages, PA 1010 resin or QA110-3-a hundred and five albronze for spacer-variety cages.

Seals:makes use of NBR or VITON, number of felted wool.

One row cross roller slewing bearing

Composed of two or 3 rings. compact structure, light-weight fat, higher production precision, tiny assembly hole and higher prerequisite for set up precision. Rollers are 1:1 cross-organized.

Can be bear axial pressure, overturning moment and massive radial drive at the exact same time,and broadly employed in lifting transportation, construction machinery and navy products.

Three row roller slewing bearing

3 row roller bearing in a position to bear all varieties of masses at the very same time, it is the largest one of the 4 structural items with massive axle and radial proportions and agency structure. Specifically suited for large machinery necessitating larger diameter, this sort of as bucket wheel stacker and reclaimer, wheel crane, marine crane, port crane, ladle turret,big tonnage truck crane,heavy machinery and so on.

Solitary row 4 point contact ball slewing bearing

Single row 4 level composed of two seat rings. has compact structure, light excess weight, and four-point speak to amongst steel ball and arc raceway. It can bear axial pressure, radial pressure and overturning instant at the identical time. The development machinery of rotary conveyor, welding manipulator, small and medium-sized crane and excavator can be chosen.

More Items

Much more Items

Far more Goods

More Items

About Us

Vast creation workshop and sturdy creation staff as a assistance,guarantee the products can be produced by required top quality and amount. andThereby improve the buyer rewards.

The over is our production equipment with sophisticated technological innovation , the steady and longevity bearinOur manufacturing facility has acquired the certificate of China’s Farm Machinery Items Quality Authentication promulgated by the Farm Equipment Merchandise Top quality Authentication CentOur PTO drive shafts enable the user effortless routine maintenance. The greasing nipples on normal crosses are positioned below angle to allow the person better accessibility. Easier obtain is also possible since of the flexible cone. We listened to the needs of our buyers and placed the greasing nipple at wide-angle PTO’s into the cross bearing. The other novelty, we launched with extensive-angle PTO push shafts is in line greasing. We wanted to furthermore simplify the upkeep and increase the lifespan of joints.re of China. g create from these equipment .

We focus in the generation of producing slewing ring bearings or turntable Bearings.The Independent R&D and product sales team in HGB , also do our ideal for specific needsWe offer you large-precision and large-good quality slewing bearings, which are widly employed in many fields,these kinds of as hoisting and conveying equipment, design engineering equipment, harbour machinery, wind electrical power technology, radar and missile launchers and so on.

Certificate

FAQ

one.Q: Are you investing company or company ?

A: We are expert slewing bearing producer with 20 years’ expertise.

two.Q: How prolonged is your shipping time?

A: Generally it is 4-5 times if the goods are in inventory. or it is forty five days if the goods are not in

stock, Also it is in accordance to amount.

3.Q: Do you offer samples ? is it totally free or extra ?

A: Sure, we could supply the sample, it is extra.

4.Q: What is your conditions of payment ?

A: Payment=1000USD, 30% T/T in progress, equilibrium just before shipment.

5.Q: Can you give special customization according to the doing work circumstances?

A: Certain, we can design and style and produce the slewing bearings for different working situations.

six.Q: How about your promise?

A: We provide lifelong right after-revenue technical services.

Get in touch with Us

Wechat/Whatsapp: +86 13083988828

Skype: +86 13083988828

Company Title: HangZhou EPG – One of the bigggest transmission company in China – Ever-Energy Transmission Bearing Technology Co., Ltd

Business office Tackle: Place B8F, Block B, shenhua road 789 – jianqiaogongshe International, XiHu District, HangZhou Metropolis,China

Phone: +86 13083988828

Worm Gear reducers are used in electrical power transmission apps necessitating high ratio speed reduction in a constrained place. The gears are utilised on correct angle, non-intersecting shafts. When effectively aligned, worms and worm gears are the quietest and smoothest sort of gearing. One drawback of worm gearing is as the ratio of this gearing boost, the effectiveness of the gearing decreases. A worm gear reducer is a proper angle velocity reducer that permits the highest pace reduction in the smallest package.Factory Address: Bearing zone in XiHu County, HangZhou Town, China

China manufacturer & factory supplier for NMRV030 in Leicester United Kingdom 60 Watt 24VDC Worm Gear Motor High Torque Gearbox Ratio 80 1 Speed Reducer With high quality best price & service

Competence for industriShear bolt torque limiter (SB) EPG Group delivers higher quality PTO shafts with tubes fastened by spring pin, cross joints with roller bearings with rollersal chains and sprockets It is our every day obstacle to source our buyers with the optimal solution – that means optimum for the required application and for the customers’ specific requirements. In some circumstances it indicates that we truly produce and manufacture very specific chain varieties for a single particular consumer. In order to be able to do so, three items are important:EPG is a skilled manufacturer and exporter that is anxious with the style, advancement and generation.

Overview

Rapid Information

- Applicable Industries:

-

Producing Plant

- Spot of Origin:Zhejiang, China

- Product NO:

-

SYF

- Colour:

-

Customer Ask for

- Ratio:

-

5-one hundred

- Material:

-

Aluminium Alloy

- Warranty:

-

one-2 Years

- Certificate:

-

ISO9001

- Bearing:

-

NSK Bearing

- Heat remedy:

-

fifty eight-sixty two HRC

- Output Type:

-

Hollow Sahft Output

- Equipment content:

-

forty five# Cast Metal

Packaging & Delivery

-

Guide Time

: -

Quantity(Baggage) 1 – 2 three – 10 >10 Est. Time(days) 3 8 To be negotiated

On the web Customization

NMRV worm gearbox reducer is a commodity with refined layout and steady enhancements, its principal characteristics are manufactured of higher good quality aluminum alloy, light-weight excess weight and non-rusting, larget output toque, clean running and reduced noise, large radiating efficiency, great looking apprearance, derable support daily life, small volume and ideal for all mounting positions.

|

Output Torque |

one.8-1760Nm |

|

Software |

Equipment Sector |

|

Gear Material |

Zepgn12-2 (BS-1400 Grade-PB2) |

|

Input Pace |

900-2800RPM |

|

Output Pace |

10-250RPM |

Principal products incorporate: manure spreading truck, potato planting/harvesting equipment, disc plough, disc harrow, grass Mower/slasher, corn and wheat thershers, seeder, mouldboard plow, deep subsoiler machines, rotary tiller, rear blade, fertilizer spreader, merge rice harvester, corn thresher, farm trailer, ridger, trencher, stubble cleaner, earth auger, cultivator and its accessories: Plow disc blades, harrowing film, plough tip and share, cultivator tine, casting parts and so on.

Relevant item

Company Profile

Packing & Shipping and delivery

China manufacturer & factory supplier for China in Tbilisi Georgia manufacturer Electric gear top plastic helical tooth M10 With high quality best price & service

EPT chains, equally normal and non-standard, are produced of: ○ Large top quality steels: proportions and adapted chemical composition for the diverse chain elements ○ The most efficient manufacturing procedures: • Specific approach for the generation of bushes enhancing the chain wear resistance ( EPT know-how) • Plates made by multi-phase processing tools making certain a standard pitch ( EPT technological innovation) ○ Sufficient mechanical and heat treatment options of chain elements: • Shot peening • Floor finishing • Case hardening, carbonitriding, quenching, tempering … • EPT®treatment • Freezing treatment • Corrosion defense coatings (GEOMET, zinc, nickel plating, …)Every process, each and every segment, every single function in EPG is demanded to be accomplished 1 action following one more, cautiously and cautiously, from material variety, reformation to producing components, from components heat treatment to computerized assembly, from high quality handle to merchandise inspection and screening and from buy dealing to right after income service.

Overview

Swift Specifics

- Applicable Industries:

-

Developing Materials Stores, Producing Plant, Equipment Fix Shops, Foodstuff & Beverage Manufacturing facility, Farms, Energy–Pushed (outer) yoke exact same as travel yoke but is mounted on the put into action. There are two sorts of shafts, domestic and metric, which are identifiable by their shapes. Domestic are generally a single of 4 designs: round, square, rectangle or splined. Metric are: bell, star or football formed. In either situation the major (entrance) shaft is the same form as the secondary shaft, only greater so that the secondary shaft suits inside. This makes it possible for a telescoping impact to consider place when the employ is elevated on the 3 pt. or in the course of a turning motion this sort of as a bailer. All shafts have to be sized prior to use. Connect the put into action to the 3 pt. and increase and assistance it. Connect the correct stop to the tractor and attempt to attach the other to the implement. If the shaft is also lengthy trim one of the shafts with a hack saw and try out it once again right up until it fits. This makes it possible for for the employ to be raised without having binding. The shafts need to overlap as a lot as allowed. & Mining

- Other Country:

-

TianJin,China

- Merchandise Identify:

-

Bevel equipment

-

Software:

EPG main generation is of farming 15-500 horsepower tractor supporting equipment, mechanical cultivation, harvesting equipment and accessories. -

products machine

- processing:

-

hobbing

- Normal:

-

Regular/customized

- This novel breather plug characteristics a spring that stops oil bubbles from forming and percolating to the outside.Color:

-

Blue

- Tooth type:

-

straight/helical

- Pressure angle:

-

twenty degree

- Package:

-

Carton

- Module:

-

M1.5/M2/M2.5/M3/M4 ect

Source Ability

- Supply Capacity:

- 5000 Piece/Parts for each Working day

Packaging & Shipping

- Packaging Details

- plastic luggage +cartons+wodden case

- Port

- TIANJIN PORT/SHANGHAI PORT/QINGDAO PORT

-

Guide Time

: -

Amount(Baggage) 1 – one hundred a hundred and one – a thousand >1000 Est. Time(times) seven 15 To be negotiated

On the web Customization

EPG supply widest selection of gearbox and velocity reducers, conveyor chains and transmission components like equipment, sprocket, racks, pulley, shaves and taper bushes and many others for a variety of purposes

Solution Description

|

solution name |

bevel gear |

|

brand identify |

EPG – The largest transmission components manufacuturer in China |

|

force angle |

20 diploma |

|

processing |

hobbing, milling , drilling , grinding , threading , shaving,shaping |

|

materials |

40CR/C45/stainless metal/brass/plastic/nylon |

|

area of spot |

TianJin,China |

Various sort gear

bevel gear

equipment shaft

spiral bevel equipment

worm gear

helical gear

spur gear

Different content

plastic equipment/nylon/pom

stainless metal

brass gear

C45/42CR gear

Specification

Application

Packing

Suggest Items

roller chain

gear

timing pulley

equipment rack

linear rail and block

ball screw

worm gear

timing belt

sprocket

Payment

Firm profile

HangZhou EPG – The greatest transmission components manufacuturer in China Electrical Products Co.,Ltd was established in HangZhou in 2008 and is a skilled company and exporter that is concerned with the design and style, growth and creation.With detailed requirments, we can also build your special developed item. Our item range consists of all kinds of helical equipment, spur gear, bevel equipment, equipment rack, worm equipment, sprockets,chains, bearings.Maintaining in head that good provider is the important to cooperating with customers, we strive to fulfill higher top quality requirements, offer you aggressive prices and guarantee prompt shipping and delivery. In this way, our items have ongoing to achieve market acceptance and consumers satisfaction in excess of the past number of a long time. We are aiming to meet the calls for of the clients all around the world..If you are interested in any of our items or would like to discuss a potential get, remember to come to feel cost-free to get in touch with us. We are hunting forward to creating successful organization relationships with new customers close to the globe in the long term.

Best China manufacturer & factory factory in Tepic Mexico manufacturer for High quality transmission driving motor spur gear agricultural machinery With high quality best price

Additionally, all our manufacturing methods are in compliance with ISO9002 expectations for a specialised supplier of a entire selection of chains, sprockets, gears, gear racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….

Overview

Rapid Details

- Applicable Industries:

-

Producing Plant

- Item Keywords and phrases:

-

transmission driving motor spur equipment

Provide Capacity

- Supply Capability:

- 5000 Piece/Items for each Month

Packaging & Shipping and delivery

- Packaging Specifics

- Neutral paper packaging, woodeSlip Clutch PTO Shaft for Compact Tractor Tillers NEW SLIPCLUTCH PTO SHAFT FOR COMPACT TRACTOR TILLERS ROTO TILLERS BUSHHOG RHINO KINGKUTTER,CARONI,MASCHIO,JOHN DEERE, MOST Designs a few different types of PTO in procedure: a non shear, shear pin and slip clutch — the last getting the most high-priced. Apply finish of non shear (r) and shear kind (l) Non shear: this is a solid yoke to yoke established up and used with the expectation that particular gear will not experience any unexpected stops. I figure that the finishing mower does not need a shear established up as the blades will slip to a degree currently being belt pushed and my other mower, the flail mower, is very forgiving in its design.n bins for outer box or in accordance to customer’s need.

- Port

- Shanghai Port / Ningbo Port

On the web Customization

We Ever-Electrical power Team with 4 branches above 1200 personnel is 1 of the largest transmission elements and machining things makers in China

Item Description

Item Description:

We specialised in producing auto gears , motorcycle gears, gearbox, unique car (power takeoff, snowmobiles, engineering vehicles) gears, generator equipment, stainless steel ice crusher and many others.

|

Material |

1020,1045,20CrMnTi, and many others. |

|

Machining Method |

Equipment Hobbing , Gear Shaping, Gear Shaving, Gear Grinding |

|

Modules |

1., 1.twenty five, 1.5, 1.75, 2., The personal computer then compares the output subassembly stack top to the length amongst the housing bearing seats and calculates the shim pack necessary for the desired bearing endplay. Using the worm-gear centerline measurement, it demonstrates assemblers how to distribute shims in between the front and rear bearings to exactly centre the gear in the housing. Measurement precision is ±0.001 in. Total cycle time, excluding loading and unloading, is less than twenty sec.2.25, 2.5….8. and so on. |

|

Warmth Therapy |

Carburizing & Quenching, Carbonitriding |

|

Regular |

DIN, ISO/GB, AGMA, JIS,ISO/TS16949:2009 |

Best China manufacturer & factory Industrial in Lokoja Nigeria neway custom injection nylon ring plastic spur gear With high quality best price

Our business pays certain consideration to customers’ needs, listening to the certain requirements of every single buyer and guaranteeing whole satisfaction.

Overview

Fast Specifics

- Relevant Industries:

-

Manufacturing Plant

- Brand Identify:

-

OEM

- Modulus:

-

1mm

- Depth:

-

50mm

- Width:

-

2mm

- Excess weight:

-

.2Kg

- Area hardness:

-

hard tooth line

- Line shape:

-

straight

- Station:

-

exterior

- Use:

-

Car

Our business is located in XiHu HangZhou Zhejiang Province. T

Provide Capability

- Supply Capacity:

- 10000000 Piece/Pieces per Thirty day period

Packaging & Supply

- Packaging Information

- pp bag, carton, personalized carton

- Port

- nb

-

Lead Time

: -

Quantity(Parts) one – 20000 >20000 EPG is a loved ones owned tiny firm that is positioned in China We supply mechanical electrical power transmission components such as: V-Belts – All types Chains – ANSI, Conveyor, Metric, Leaf Sprockets – ANSI standard, Conveyor, Cast Gears – Spur, Rack, Miter, Bevel, Worm, Metric Couplings – Flange, Jaw, Chain, Rigid, Zero Backlash AC & DC Motors and Controls Belt Drives, Synchronous and Non-Synchronous Bearings – Ball, Roller, and Mounted Est. Time(days) 15 To be negotiated

On the internet Customization

Product Description

Industrial neway custom made injection nylon ring plastic spur equipment

Resistant to dress in and tear

Solution specifics

| Modulus | 1mm |

| Depth | 50mm |

| Width | 2mm |

| Bodyweight | .2Kg |

| Materials | plastic |

| Form | planetary equipment |

| Area hardness | hard tooth line |

| Line shape | straight |

| Station | exterior |

| Use | Auto |

Firm Info

HangZhou EPT Plastic Co.,Ltd was founded in 1999.It is located in Ningbo,with the practical transportation conditions.The firm is specialised in developing and producing all sorts of Plastic molds and products,which are broadly serves the industrial areas of the photoelectric,car,IT, digital and electrical appliances, health care products.In the recent many years,the firm has produced fantastic efforts on planning and production the plastic gears,this kind of as spur gear,helical gears,worms and many others.which are primarily utilized in auto headlights,rear-see mirrors,food processors,printers,espresso equipment and so on.Larger precision,reduced noise and quality support are the instructions of our attempts.

Apart from the injection workshop,the firm also has its personal mold-produced plant with the superior CAD/CAM/CAE products and a expert team for developing and developing the molds,so that it can supply the customers with the high-precision goods.

The organization aims to give the mostly and thoughtful service to buyers with the most specialised abilities and enthusiasm.Now,we sincerely welcome the customers from equally the domestic and global marketplace to cooperate and build hand in hand.

Our certificates

Our Rewards

Enthusiasm,Top quality,Honest,Services.

The company is specialised in designing and manufacturing aOnce the PTO has begun to energy the attachment, steadily enhance the throttle until you get to the functioning pace. The common working RPM (revolutions for each moment) for a tractor mounted PTO is 540 RPM, even though there are tractor models that rev larger. Often refer to your particular tractor design for recommendations prior to initial-time use.ll varieties of Plastic molds and goods,

which are broadly serves the industrial places of the photoelectric, auto, IT, digital and electrical appliances, medical gear.

The business also has innovative CAD/CAM/CAE equipment and a skilled crew for creating and creating the molds,

so that it can supply the buyers with the large-precision products and good quality service.

Best China manufacturer & factory factory in Columbus United States manufacturer for manufacturer cnc machining helical bronze brass steel electric motor driving worm shaft and gear With high quality best price

With many years’ experience in this line, we will be trusted by our advantages in competitive price, one-time delivery, prompt response, on-hand engineering support and good after-sales services.Additionally, all our production procedures are in compliance with ISO9001 standards.

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant

- Local Service Location:

-

None

- Product Name:

-

Brass Worm Gear

- Application:

-

Auto Part

- Surface treatment:

-

Plating,According to the drawing

- Heat treatment:

-

Quenching,Nitriding,According to the product

- Processing:

-

Gear Hobbing, Milling, Shaping, Broaching,Shaving, Grinding

- Standard:

-

1. DIN, ISO/GB, AGMA, JIS,ISO/TS16949:2009

- Tolerance:

-

Outer Diameter Length Dimension

Supply Ability

- Supply Ability:

- 5000 Piece/Pieces per Month

To eliminate contact-pattern inconsistencies, EPT developed an automated centering machine that accurately measures each worm and gear subassembly, as well as the reducer housing and bearing covers. A computer records the data and calculates the thickness and location of shims required to exactly center the gear under the worm shaft and, at the same time, provides the appropriate end 1play for the output tapered-roller bearings. This maximizes operating efficiency and minimizes temperature rise.

Packaging & Delivery

- Packaging Details

- Neutral paper packaging, wooden boxes for outer box or according to customer’s demand

- Port

- Shanghai / Ningbo

-

Lead Time

: -

Quantity(Pieces) 1 – 1000 >1000 The EP Line PTO drive shafts are recognizable because of the EP Line patented coupling mechanism and the flexible cone. The PTO drive shafts are distinguished through user-friendliness, compactness and appealing design.

Est. Time(days) 15 To be negotiated

Online Customization

We Ever-Power Group with 4 branches over 1200 workers is one of the biggest transmission parts and machining items manufacturers in China

Product Description

manufacturer cnc machining helical bronze brass steel electric motor driving worm shaft and gear

(1). All kinds of gears, shaft, gear shaft, precision gear and CNC gear.

(2). Specialized in manufacturing all kinds of automobile transmission part based on drawings

(3). Material: ductile cast iron, carbon steel, alloy steel , stainless steel, , bronze/brass

(4). Modules: M1 to M8

(5). Meets ISO, DIN and ASTM standards

(6). Specification : According to the the drawing

|

Material |

Carbon Steel |

SAE1020, SAE1045, Cr12, 40Cr, Y15Pb, 1214Letc |

|

Alloy Steel |

20CrMnTi, 16MnCr5, 20CrMnMo, 41CrMo, 17CrNiMo5etc |

|

|

Brass/Bronze |

HPb59-1, H70, CuZn39Pb2, CuZn40Pb2, C38000, CuZn40etc |

|

|

Tolerance Control |

Outer Diameter |

Based on drawing |

|

Length Dimension |

Based on drawing |

|

|

Machining Process |

Gear Hobbing, Gear Milling, Gear Shaping, Gear Broaching, Gear Shaving, Gear Grinding and Gear Lapping |

|

|

Teeth Accuracy |

DIN Class 4, ISO/GB Class 4, AGMA Class 13, JIS Class 0 |

|

|

Modules |

1.0, 1.25, 1.5, 1.75, 2.0, 2.25, 2.5….8.0 etc |

|

|

Heat Treatment |

Quenching & Tempering, Carburizing & Quenching, High-frequency Hardening, Carbonitriding |

|

|

Surface Treatment |

Blacking, Polishing, Anodization, Chrome Plating, Zinc Plating, Nickel Plating |

|

|

Standard |

1. DIN, ISO/GB, AGMA, JIS,ISO/TS16949:2009 |

|

Product Photos : EPG major production is of farming 15-500 horsepower tractor supporting machinery, mechanical cultivation, harvesting machinery and accessories.

Packaging & Shipping