Best Male Thread With Helical Shank French Fire Hose Quick Coupling for Your Industrial Needs

The Male Thread with Helical Shank French Fire Hose Quick Coupling is designed to meet the EN14420-8 or NF E29572 standards. It is made using high-quality materials such as brass, stainless steel, aluminum, and polypropylene. It is highly efficient and can be used with DIN2817 safety clamp. The working pressure of this coupling is 10 bar. This coupling is widely used in various industries such as oil, chemical, fire protection, paper manufacture, construction, and metallurgy because of its ease of use and reliability.

Features and Benefits

The Male Thread with Helical Shank French Fire Hose Quick Coupling is a symmetrical coupling that can be easily connected by joining the lugs and turning the locking ring to ensure a good connection. Some of the key benefits include:

- Simple and easy connection

- Has a locking ring and soft seal

- Large free flow area

- Aluminum couplings are lighter in weight than stainless steel

- Suitable for water, fluids, hydrocarbons, chemicals, and dry loose materials

Additionally, this coupling is light, flexible, and interchangeable, making it an economical choice for your industrial needs.

Product Details

| Product Name: | Guillemin Camlock Coupling |

| Sizes: | 1” – 4” (DN25-DN100) |

| MOQ: | 50 pcs |

| Certificates: | CE, ISO9001:2015 |

| Standard: | EN14420-8 /NF E29572 |

| Material: | Stainless steel 316/ 304, Aluminum, PP |

| Working pressure: | 10 bar |

| Feature: | Light, flexible, and interchangeable. To connect and disconnect without a tool. Economical |

| Application: | Widely used in oil, chemical industry, fire fighting, paper manufacture, construction, and metallurgy |

| HS code: | 7609000000 |

Why Choose Us?

Our company has been in the industry for over 10 years, and we have a highly experienced team that can manufacture products according to specific drawings from customers. We are ISO9001, CE, and SGS certified, ensuring that both quality and service are highly guaranteed. We offer prompt delivery and strict control on quality. Our well-trained sale service team is always ready to assist you with any queries. We also welcome OEM/ODM projects and can produce customized products based on your needs.

We supply various industrial products such as agricultural gearboxes, power output shafts, sprockets, hydraulic couplings, worm gear reducers, racks, roller chains, pulleys, planetary gearboxes, timing pulleys, bushings, and many more. We are committed to providing high-quality products, preferential prices, and thoughtful services to meet your industrial needs. Customers are welcome to customize with drawings and samples.

Frequently Asked Questions

1. What is the working pressure of the Male Thread with Helical Shank French Fire Hose Quick Coupling?

The working pressure of this coupling is 10 bar.

2. What are the materials used to manufacture the coupling?

The Male Thread with Helical Shank French Fire Hose Quick Coupling is made using high-quality materials such as brass, stainless steel, aluminum, and polypropylene.

3. What industries can use this coupling?

This coupling is widely used in various industries such as oil, chemical, fire protection, paper manufacture, construction, and metallurgy.

4. Can I get customized products based on my needs?

Yes, we welcome OEM/ODM projects and can produce customized products based on your needs.

5. What other industrial products does your company supply?

We supply various industrial products such as agricultural gearboxes, power output shafts, sprockets, hydraulic couplings, worm gear reducers, racks, roller chains, pulleys, planetary gearboxes, timing pulleys, bushings, and many more.

Introduction to the Performance Characteristics of Helical Coupling

Helical coupling is a type of coupling that can transmit torque and motion between two shafts that are not parallel to each other. It has the following performance characteristics:

1. High Torque Transmission Capacity

Helical coupling can transmit high torque due to its high torsional stiffness and high torsion rigidity, which makes it suitable for high-power transmission.

2. Good Compensation for Axial, Radial and Angular Misalignments

Helical coupling can compensate for a certain degree of axial, radial and angular misalignments, which effectively reduces the load on the shaft and ensures the transmission accuracy.

3. High Precision

Helical coupling has high precision, which ensures the accuracy of transmission and can effectively avoid vibration and noise.

4. Easy Installation and Maintenance

Helical coupling is easy to install and maintain, which not only saves time and effort, but also reduces the cost of maintenance.

Types and Characteristics of Helical Coupling

Helical coupling can be divided into two types: single-piece helical coupling and double-piece helical coupling. The single-piece helical coupling can compensate for a small degree of misalignment, while the double-piece helical coupling can compensate for a larger degree of misalignment. The material used to make helical coupling can be divided into two types: metal and non-metal.

The metal helical coupling includes aluminum alloy, stainless steel, and carbon steel. The aluminum alloy has the advantages of light weight and corrosion resistance. The stainless steel has the advantages of high strength and corrosion resistance. The carbon steel has the advantages of high hardness and wear resistance. The non-metal helical coupling includes nylon and polyurethane. The nylon has the advantages of high toughness and impact resistance, while the polyurethane has the advantages of high elasticity and shock absorption.

Advantages of Helical Coupling Made of Different Materials

The advantages of helical coupling made of different materials are as follows:

1. Aluminum Alloy Helical Coupling

The aluminum alloy helical coupling has the advantages of light weight, corrosion resistance, and good electrical conductivity, which makes it suitable for use in servo motors, robotics, and other industries.

2. Stainless Steel Helical Coupling

The stainless steel helical coupling has the advantages of high strength, corrosion resistance, and high temperature resistance, which makes it suitable for use in CNC machines, pumps, and other industries.

3. Carbon Steel Helical Coupling

The carbon steel helical coupling has the advantages of high hardness, wear resistance, and long service life, which makes it suitable for use in packaging machinery, printing machinery, and other industries.

4. Nylon Helical Coupling

The nylon helical coupling has the advantages of high toughness, impact resistance, and good shock absorption, which makes it suitable for use in medical devices, material handling, and other industries.

5. Polyurethane Helical Coupling

The polyurethane helical coupling has the advantages of high elasticity, shock absorption, and good chemical resistance, which makes it suitable for use in transportation equipment, agricultural machinery, and other industries.

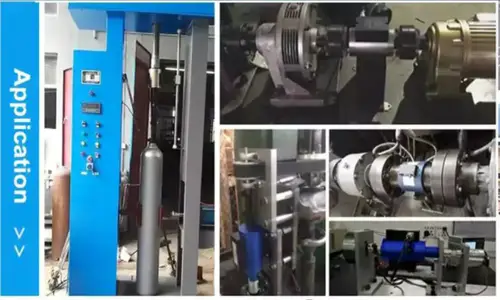

Application of Helical Coupling in Various Industries

Helical coupling has wide application in CNC machines, servo motors, material handling, medical devices, packaging machinery, and other fields. Its value and importance in various fields are reflected in the following aspects:

1. CNC Machines

Helical coupling is widely used in CNC machines, which can effectively transmit torque and motion between the spindle motor and the ball screw, ensuring the high precision and stability of the machine.

2. Servo Motors

Helical coupling is widely used in servo motors, which can effectively transmit torque and motion between the motor and the load, ensuring the high precision and fast response of the motor.

3. Material Handling

Helical coupling is widely used in material handling equipment, which can effectively transmit torque and motion between the motor and the conveyor belt, ensuring the smooth operation of the equipment.

4. Medical Devices

Helical coupling is widely used in medical devices, which can effectively transmit torque and motion between the motor and the load, ensuring the high precision and safety of the device.

5. Packaging Machinery

Helical coupling is widely used in packaging machinery, which can effectively transmit torque and motion between the motor and the packaging machine, ensuring the high precision and speed of the machine.

Future Development Trends and Opportunities of Helical Coupling

The future development trends and opportunities of helical coupling products are as follows:

1. High Precision and Miniaturization

With the continuous development of new materials and new technologies, helical coupling products will become more precise and miniaturized, which will effectively improve the accuracy and reliability of transmission.

2. Intelligent and Networked

Intelligent and networked helical coupling products will become more and more popular, which will effectively improve the efficiency and automation of equipment.

3. Customization and Personalization

With the continuous development of digital manufacturing technology, customized and personalized helical coupling products will become more and more popular, which will effectively meet the diverse needs of customers.

Suggestions and Outlook

In the future, helical coupling products will continue to develop towards high precision, miniaturization, intelligence, and customization. As an eCommerce seller of replacement parts, it is very important to keep up with the development trend of helical coupling products, and provide customers with quality products and services.

How to Choose a Suitable Helical Coupling

When choosing a suitable helical coupling, the following aspects should be analyzed:

1. Torque Requirements

The torque requirements of the application should be considered, including the maximum torque and the continuous torque.

2. Misalignment Tolerance

The misalignment tolerance of the application should be considered, including the axial misalignment, radial misalignment, and angular misalignment.

3. Operational Speed

The operational speed of the application should be considered, including the maximum speed and the continuous speed.

4. Environmental Conditions

The environmental conditions of the application should be considered, including the temperature, humidity, and corrosion.

5. Space Constraints

The space constraints of the application should be considered, including the length, diameter, and weight of the coupling.

6. Installation

The installation of the coupling should be considered, including the type of shaft connection, the type of coupling, and the method of fixing.

Summary

Helical coupling is a type of coupling that can transmit torque and motion between two shafts that are not parallel to each other. It has the performance characteristics of high torque transmission capacity, good compensation for axial, radial and angular misalignments, high precision, and easy installation and maintenance. Helical coupling can be divided into two types: single-piece helical coupling and double-piece helical coupling, and the material used to make helical coupling can be divided into metal and non-metal. Helical coupling has wide application in CNC machines, servo motors, material handling, medical devices, packaging machinery, and other fields, and its future development trends and opportunities include high precision and miniaturization, intelligence and networking, and customization and personalization. When choosing a suitable helical coupling, the torque requirements, misalignment tolerance, operational speed, environmental conditions, space constraints, and installation should be analyzed.